Preparing method of capillary tube chromatographic columns

A technology of capillary chromatographic column and capillary column, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low preparation success rate, complicated preparation process of capillary chromatographic column, long preparation cycle, etc., and achieve the effect of simple and fast method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

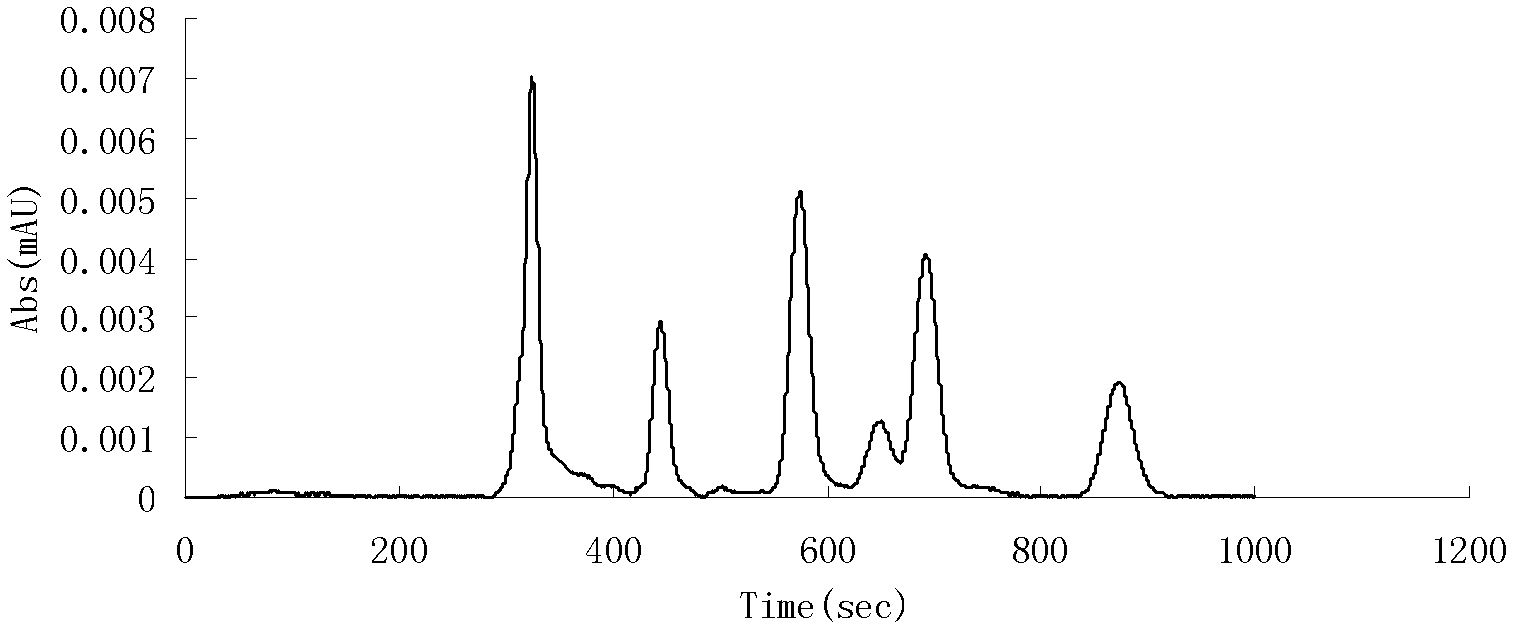

Embodiment 1

[0026] Preparation of C18 reversed-phase capillary column

[0027] 1. Preparation of homogenate

[0028] Weigh 50 mg of C18 reversed-phase silica gel bonded stationary phase with a particle size of 3 μm, add the obtained filler into 10 ml of acetone to prepare a homogenate with a concentration of 5 mg / ml, and shake the solution by hand to mix it evenly, and then Oscillate in an oscillator for 10 minutes to evenly distribute the filler in acetone.

[0029] 2. Prepare the outlet plunger

[0030] Cut 8 elastic quartz capillaries with an inner diameter of 100 μm and an outer diameter of 365 μm, each with a length of 8 cm, place one end of the capillary in a centrifuge tube containing a 110 μm porous silica gel ball, and press a single porous silica gel ball into one end of the capillary, Then use a quartz capillary with an outer diameter of 90 mm to push the single-particle stopper into the end of the capillary as an outlet plunger, and the preparation method of the plunger for ...

Embodiment 2

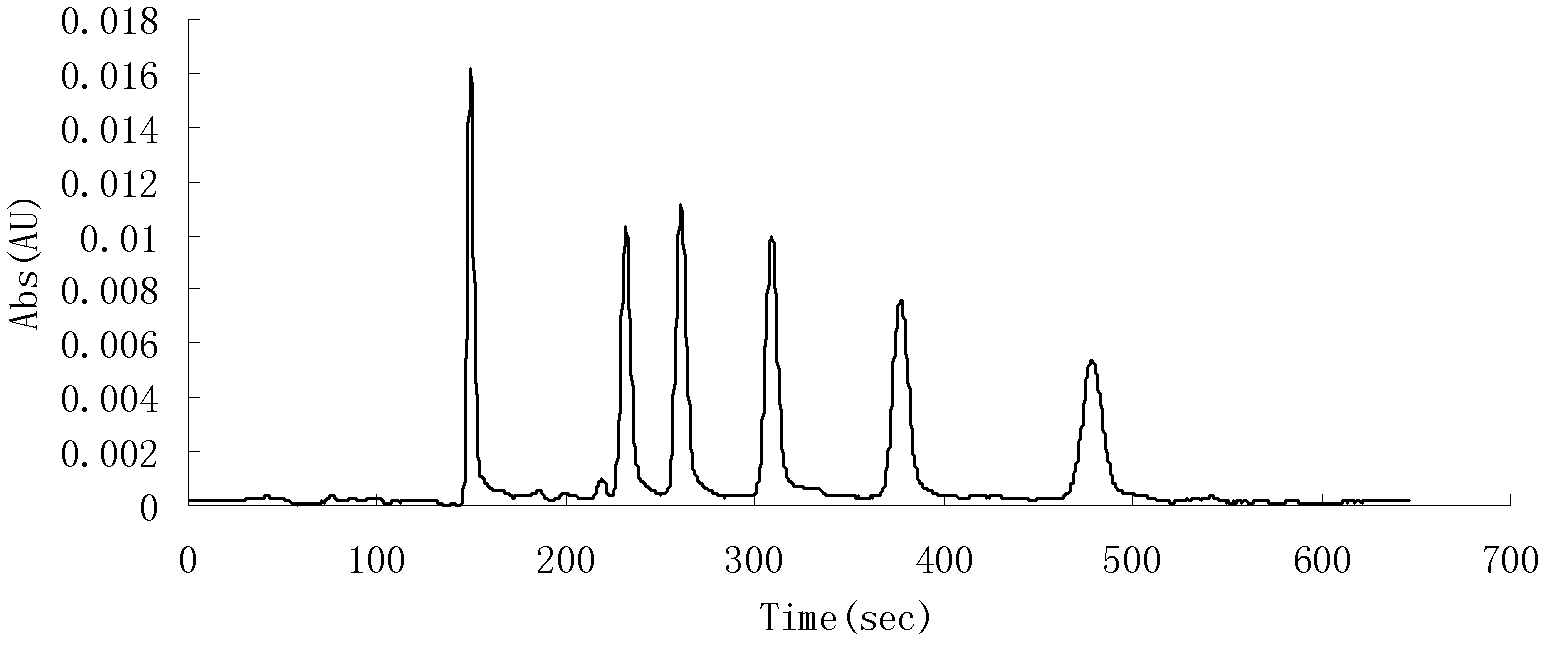

[0037] Preparation of Capillary Electrochromatographic Columns

[0038] The filler and filling method of the electrochromatographic column are the same as in Example 1, except that the length of the capillary taken is 16cm, and the filling length is 8cm. A 5mm detection window is burned behind the column for ultraviolet detection, and the prepared column is carried out. Evaluation of electrochromatographic separation modes. Sample test results: the sample is a mixture of thiourea, toluene, ethylbenzene, propylbenzene, butylbenzene, and pentabenzene, the buffer system is Tris-HCl (50mM, pH 8.0) / ACN (40 / 60), the separation voltage is 10kV, and the detection wavelength is 214nm. The result is as figure 2 As shown, the column efficiency of the last component, pentylene, is 125,800 plates per meter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com