Zero offset test compensation system of multi-channel capacitor type MEMS (micro-electromechanical system) acceleration sensor

An acceleration sensor and zero offset technology, which is applied in the field of microelectronics, can solve the problems of cumbersome operation and time-consuming measurement of multiple accelerometers, and achieve the effects of simple operation, high degree of automation, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

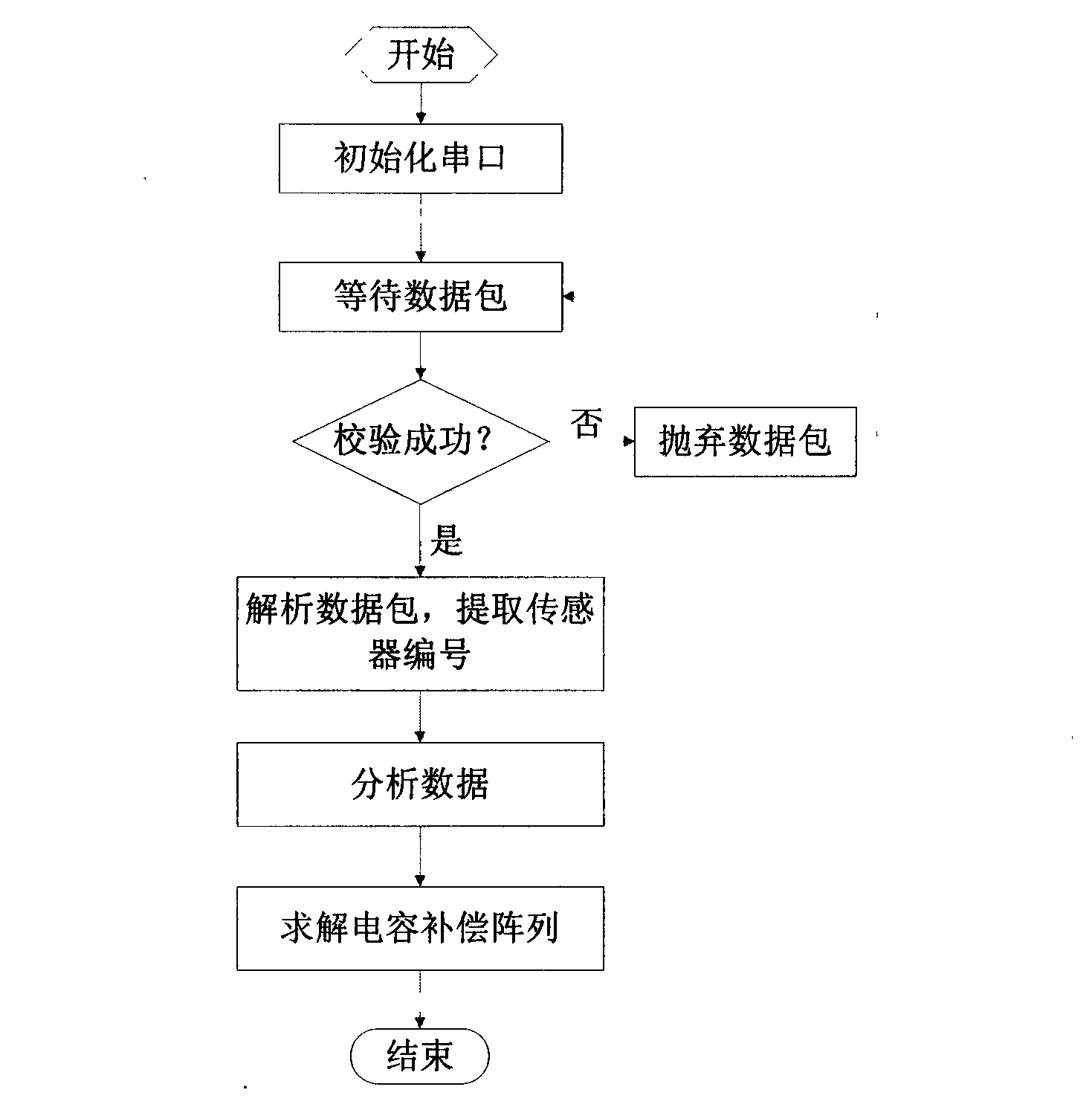

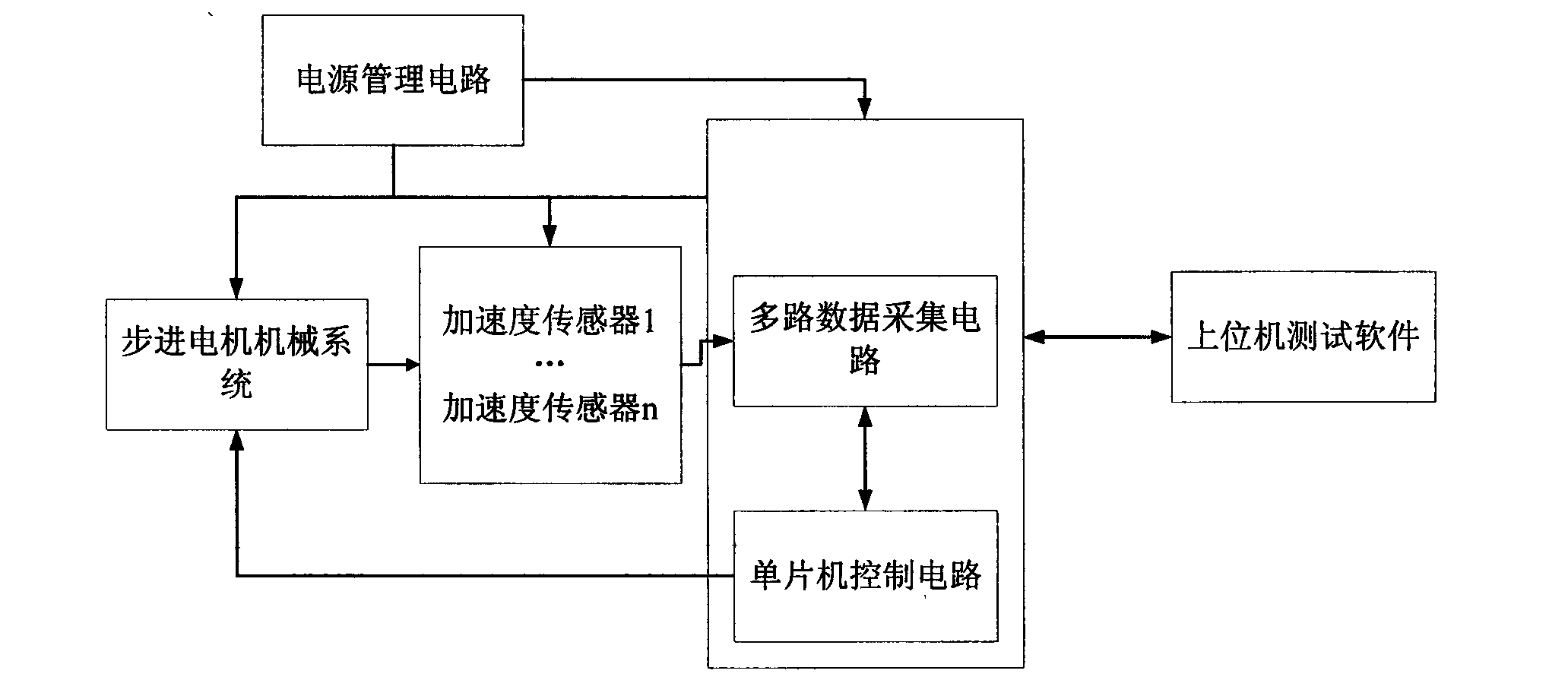

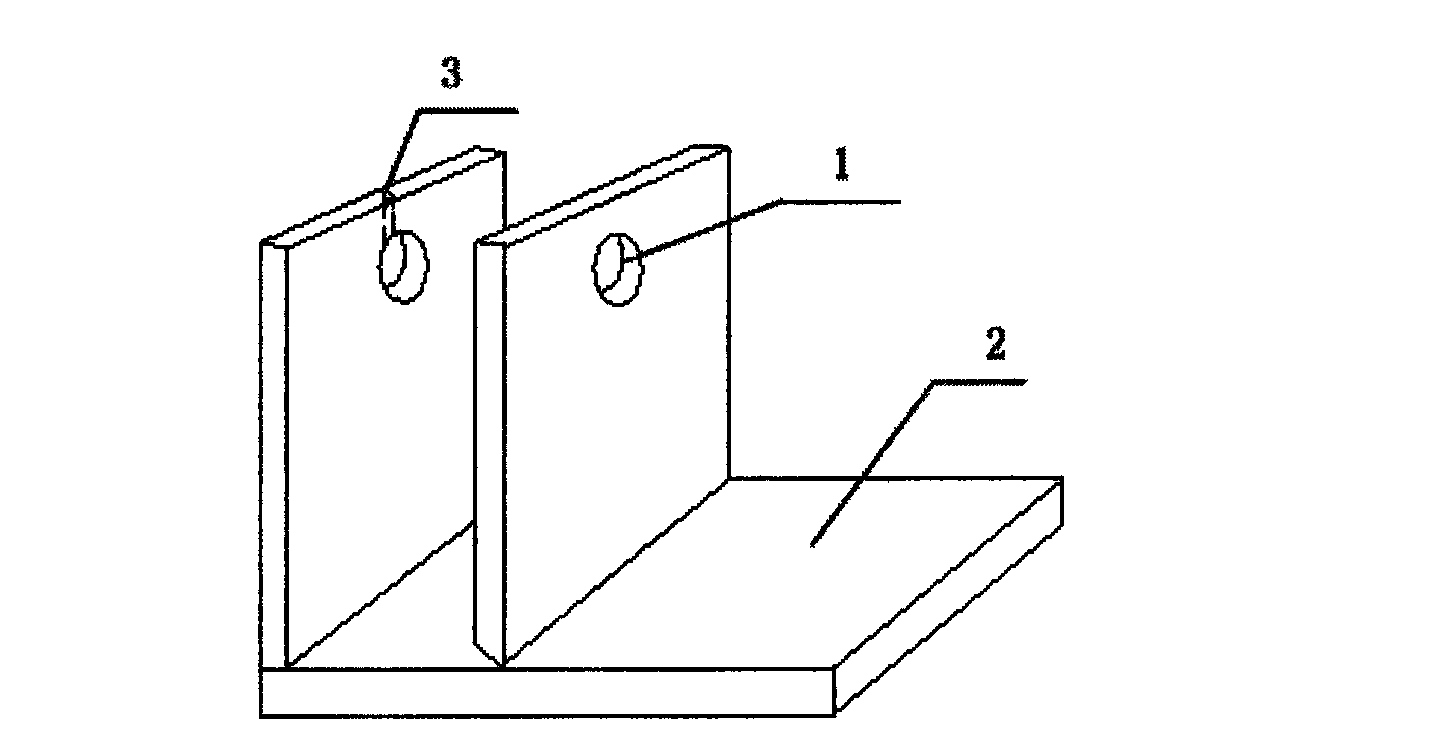

[0017] Example 1: Combining figure 1 , figure 2 , image 3 , the present invention is a multi-channel capacitive MEMS acceleration sensor zero point offset test compensation device, which is composed of a stepping motor mechanical system, a multi-channel capacitive MEMS acceleration sensor, a multi-channel data acquisition circuit, a single-chip microcomputer control circuit and a power management system. Yes, the stepper motor mechanical system is connected to multi-channel capacitive MEMS acceleration sensors, the multi-channel capacitive MEMS acceleration sensors are connected to multiple data acquisition circuits, the multi-channel data acquisition circuits are connected to the single-chip microcomputer control circuit, and the power management circuits are respectively connected to the stepping motor mechanical system , Multi-channel capacitive MEMS acceleration sensor, multi-channel data acquisition circuit and single-chip microcomputer control circuit.

[0018] The p...

Embodiment 2

[0022] Embodiment 2: Generally, a capacitor array that changes by a certain step size can be provided between the driving signal and the detection signal of the interface circuit of the MEMS capacitive acceleration sensor, so as to realize the compensation of the capacitance deviation of the sensitive structure. The capacitor array of the present invention includes 500fF, 250fF, 125fF, 62.5fF, 31.25fF, 15.625fF. In each subunit in the capacitor array, the capacitors in the unit can be connected to fixed electrodes and movable beams through switches. The parallel connection of compensation capacitors with different capacitances and sensor sensitive capacitors can be realized by controlling each switch. With this setting, the capacitance compensation array can adjust the zero offset caused by the production process to a certain extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com