Manufacturing method of gate controlled diode semiconductor device

A technology for gate-controlled diodes and manufacturing methods, which is applied in the manufacture of gate-controlled diode semiconductor devices and the field of semiconductor device manufacturing, can solve problems such as driving current reduction, and achieve large driving currents, small sub-threshold swings, and low manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

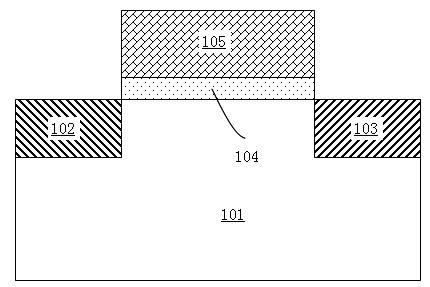

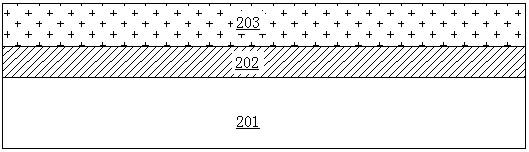

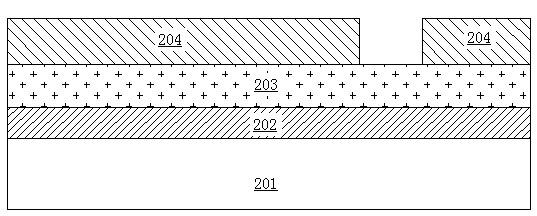

[0016] Hereinafter, an exemplary embodiment of the present invention will be described in detail with reference to the accompanying drawings. In the figure, for convenience of description, the thickness of layers and regions are enlarged or reduced, and the size shown does not represent the actual size. Although these figures do not completely accurately reflect the actual size of the device, they still completely reflect the mutual position between the regions and the constituent structures, especially the upper and lower and adjacent relationships between the constituent structures.

[0017] The reference figure is a schematic diagram of an idealized embodiment of the present invention. The embodiment shown in the present invention should not be regarded as limited to the specific shape of the area shown in the figure, but includes the resulting shape, such as deviations caused by manufacturing. For example, the curves obtained by etching usually have the characteristics of ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com