Nanocrystalline deposition density process control monitoring method, module and manufacturing method thereof

A technology for process control and monitoring modules, applied in semiconductor/solid-state device testing/measurement, electrical components, electrical solid-state devices, etc., can solve the problem of inability to timely feedback the nanocrystal deposition process, and achieve the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

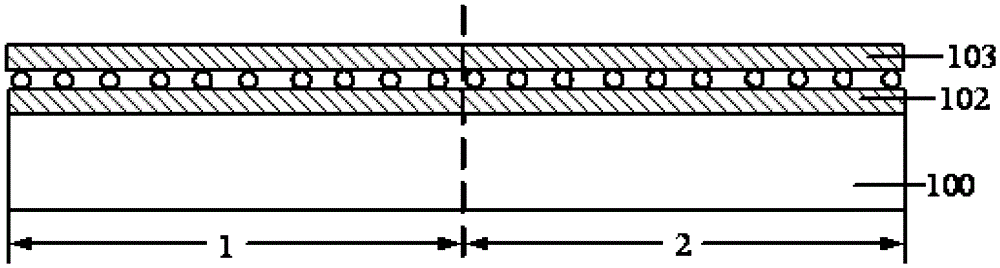

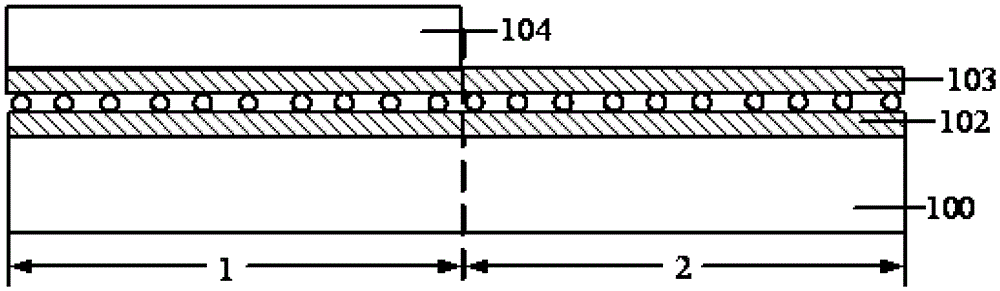

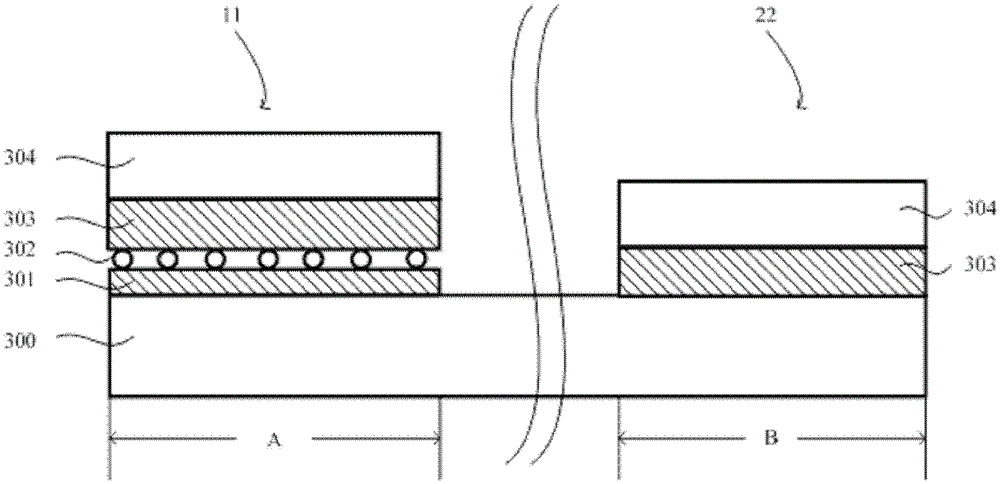

[0038] The present invention provides a testing method to realize non-destructive testing of nanocrystalline particle deposition process parameters. The invention includes the design of a nanometer process monitoring graphic module, a corresponding graphic module process flow, and an electrical testing method for the graphic module.

[0039] Specifically, the present invention designs a set of process monitoring modules in the scribe grooves of the silicon wafer, the process monitoring modules contain the deposition layer of nanocrystals, and the process of depositing particles of the nanocrystal layer is characterized by the test of the process monitoring module parameter. In the present invention, the contact holes are filled with metal on the device structure in the chip area to form electrodes, and electrodes are also formed on the process monitoring module, and then the nanocrystal deposition density is measured through the electrodes. That is, the nanocrystal deposition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com