Patents

Literature

42 results about "Process control monitoring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the application of integrated circuits, process control monitoring (PCM) is the procedure followed to obtain detailed information about the process used. PCM is associated with designing and fabricating special structures that can monitor technology specific parameters such as Vₜₕ in CMOS and Vbe in bipolars. These structures are placed across the wafer at specific locations along with the chip produced so that a closer look into the process variation is possible.

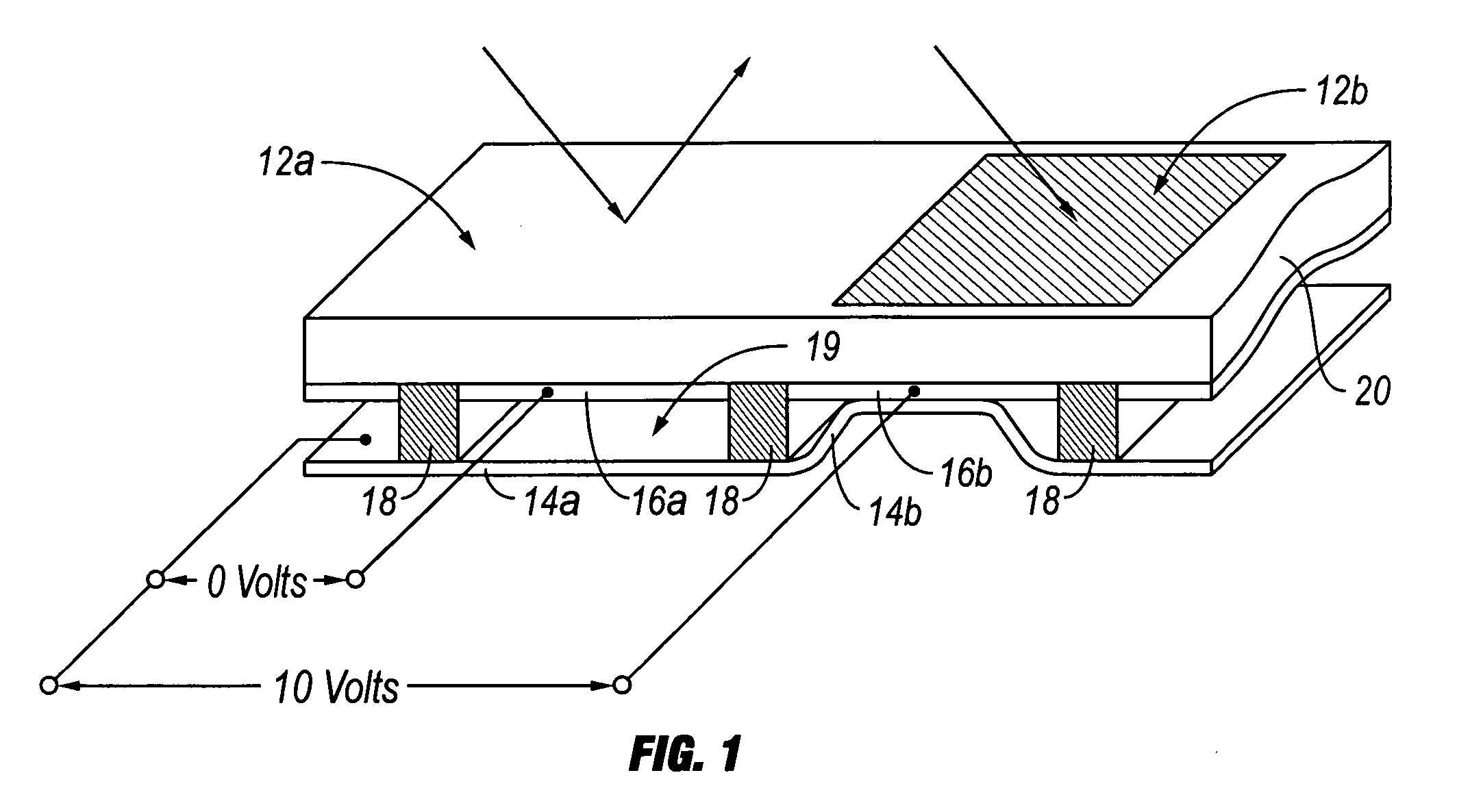

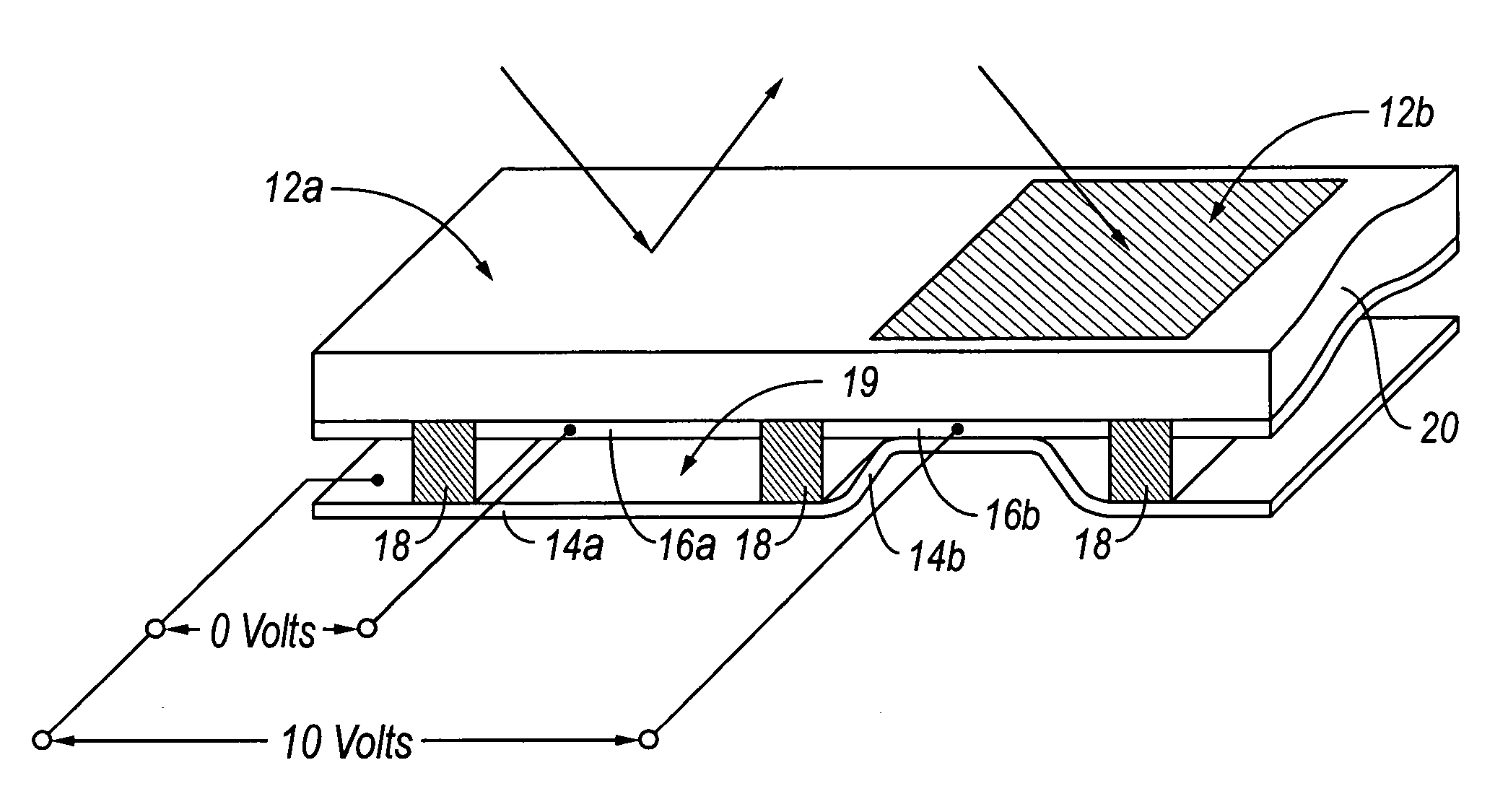

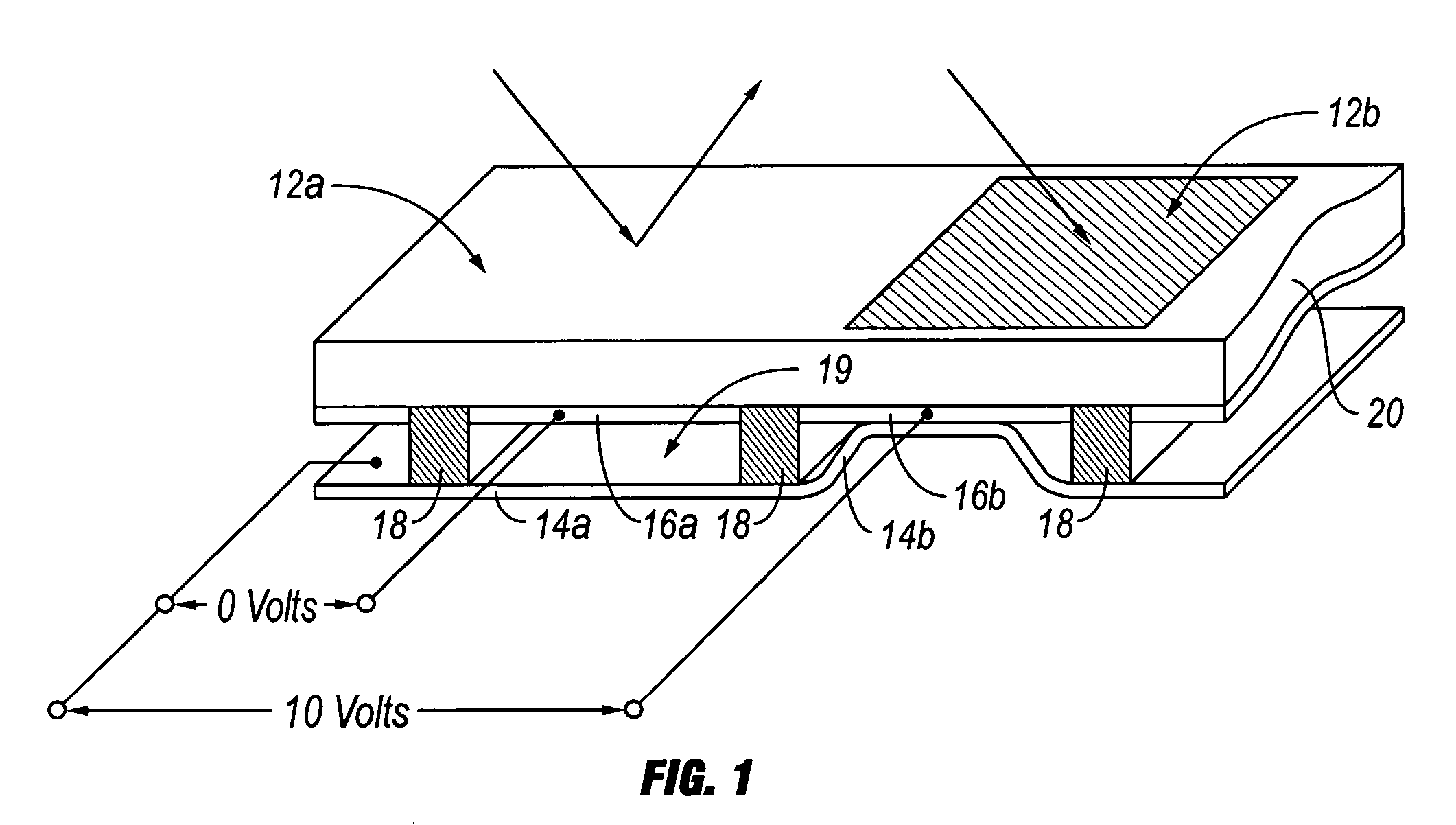

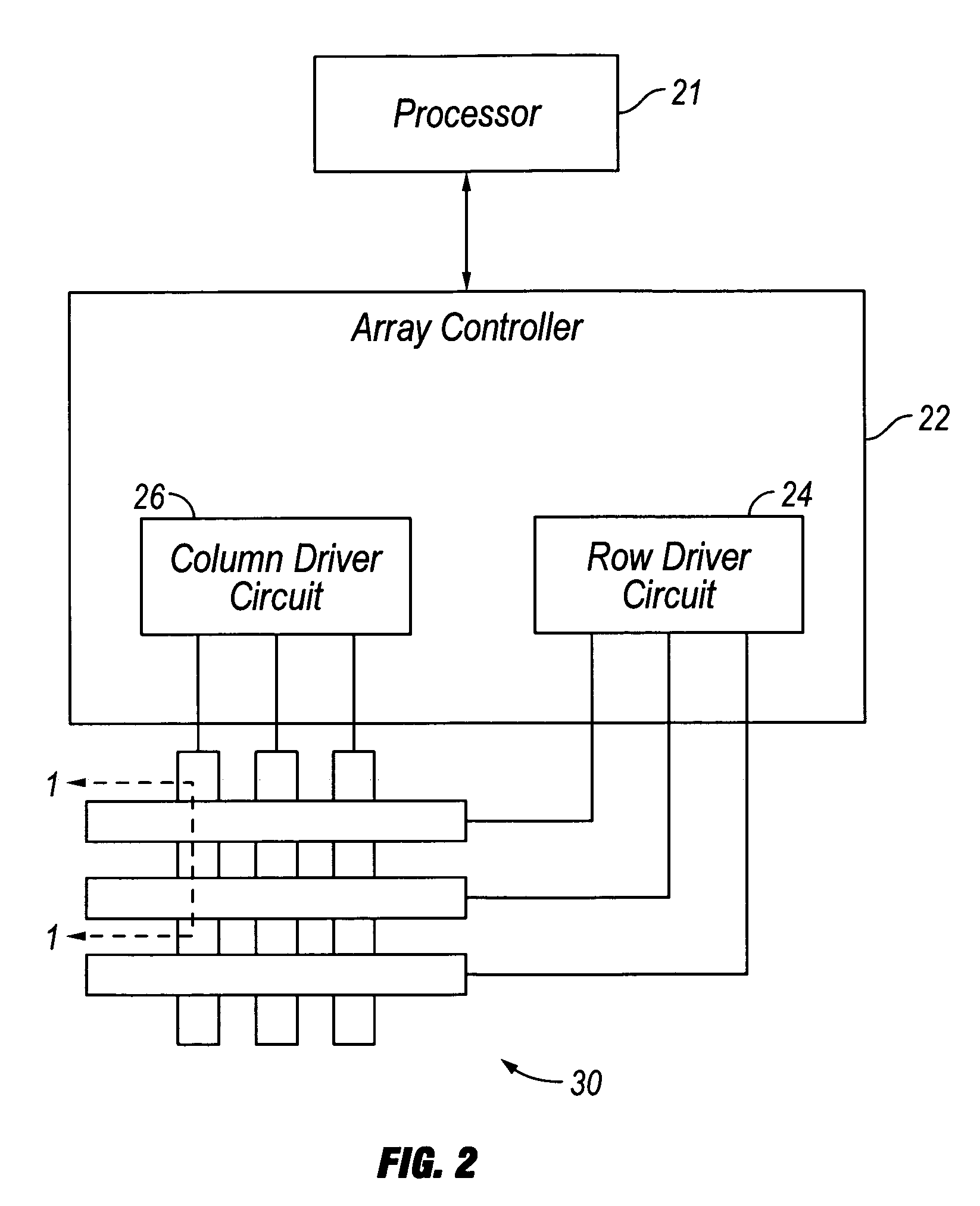

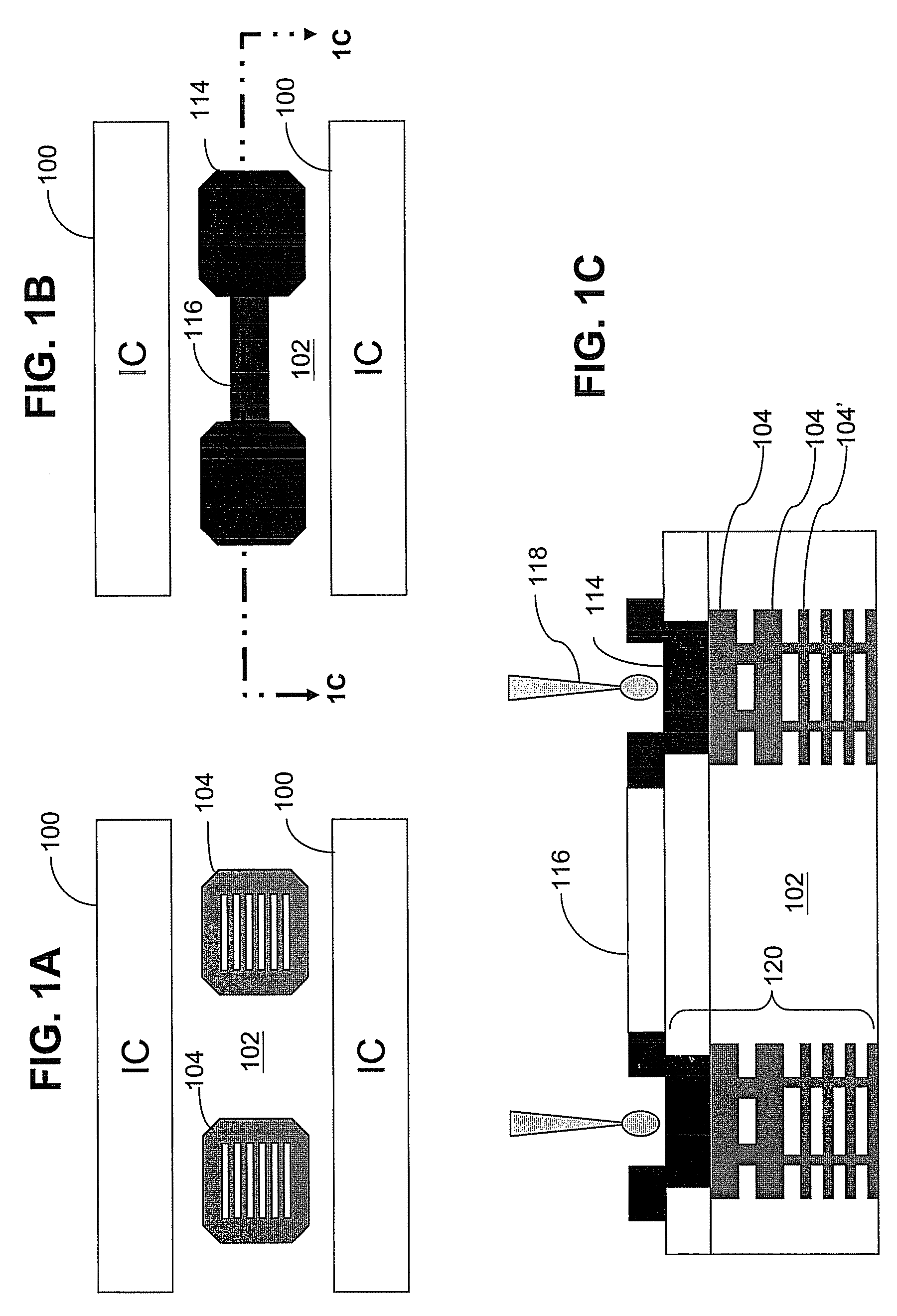

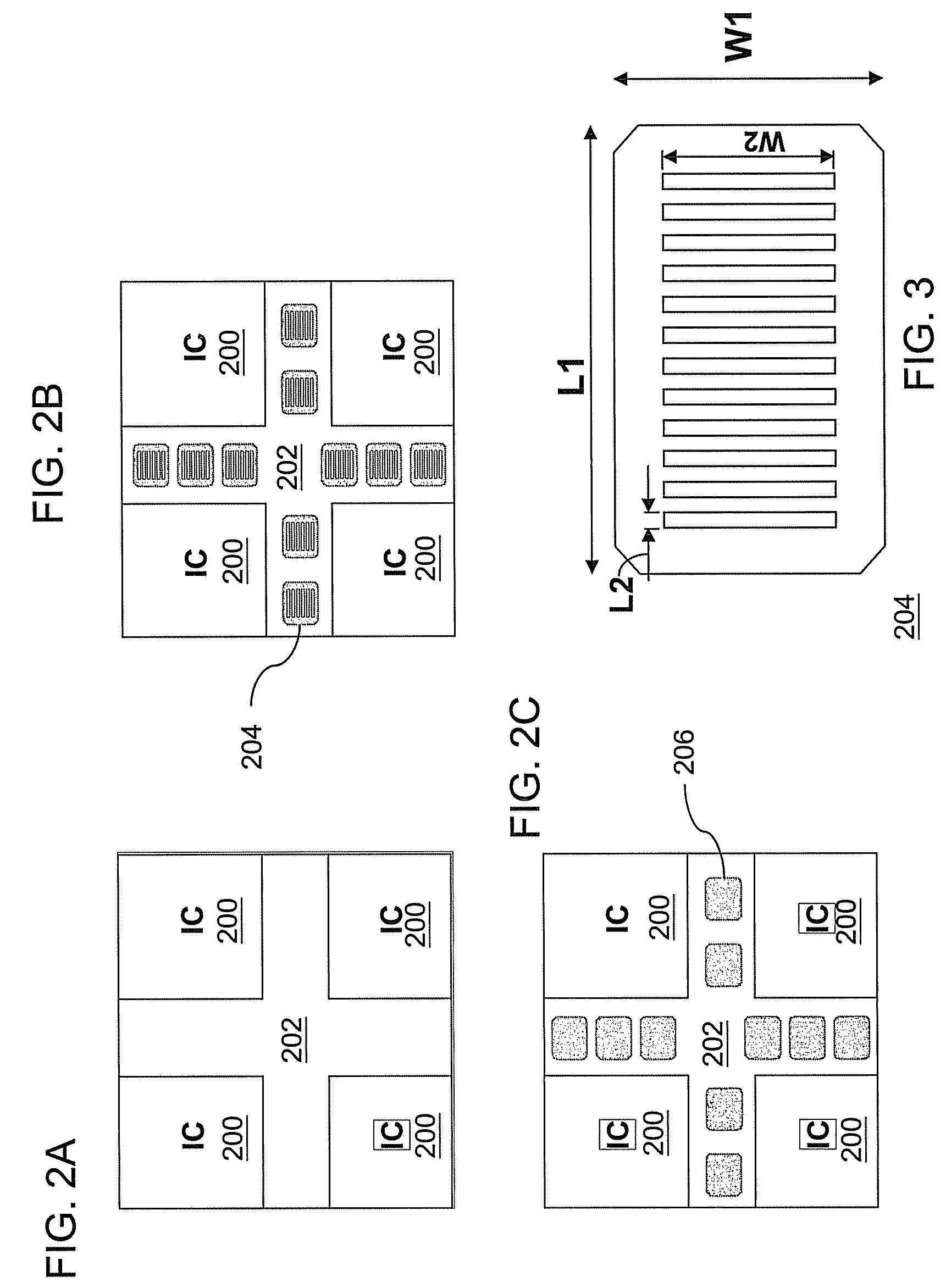

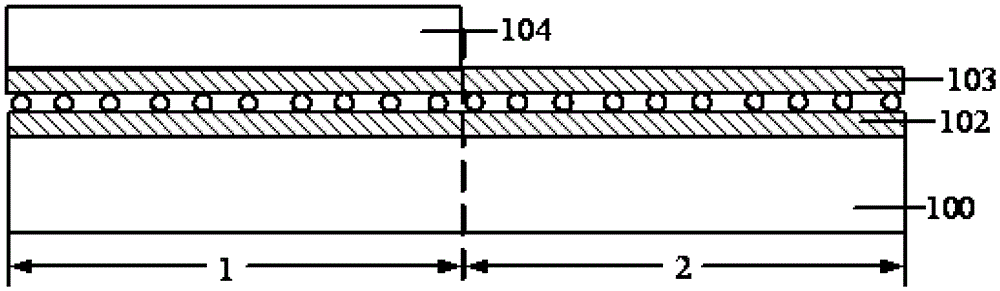

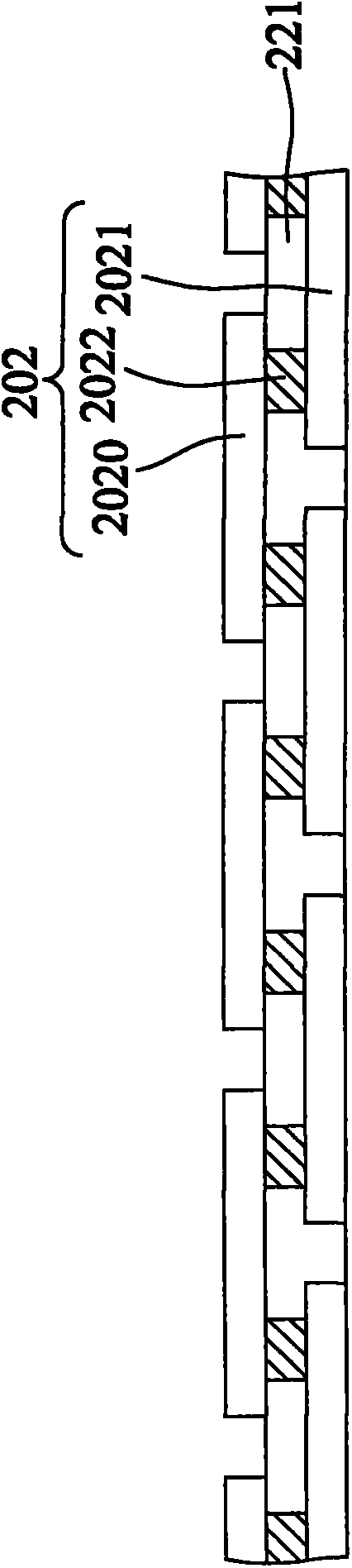

Test structure for semiconductor chip

InactiveUS20080277659A1Avoid damageSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSemiconductor chipEngineering

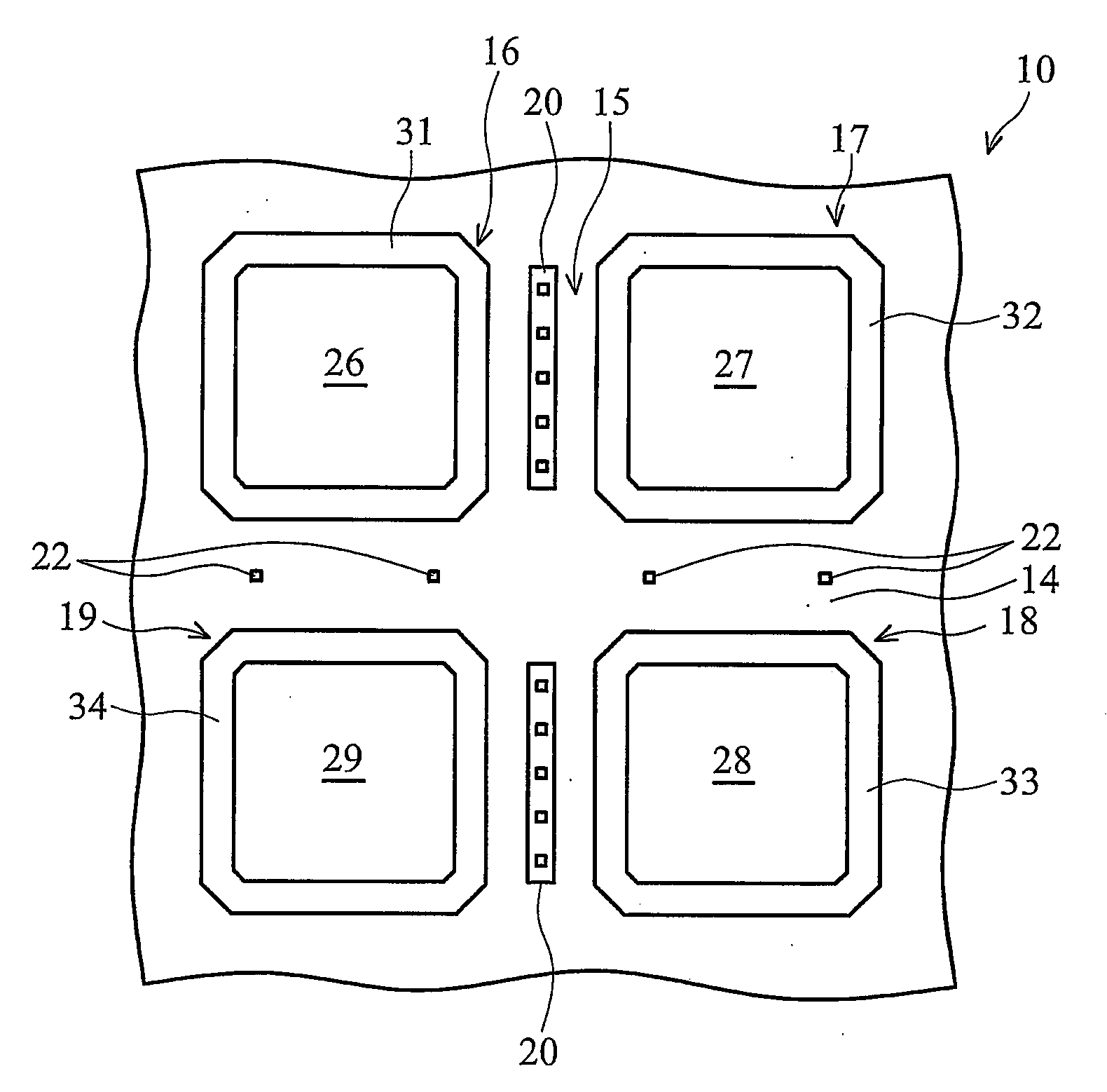

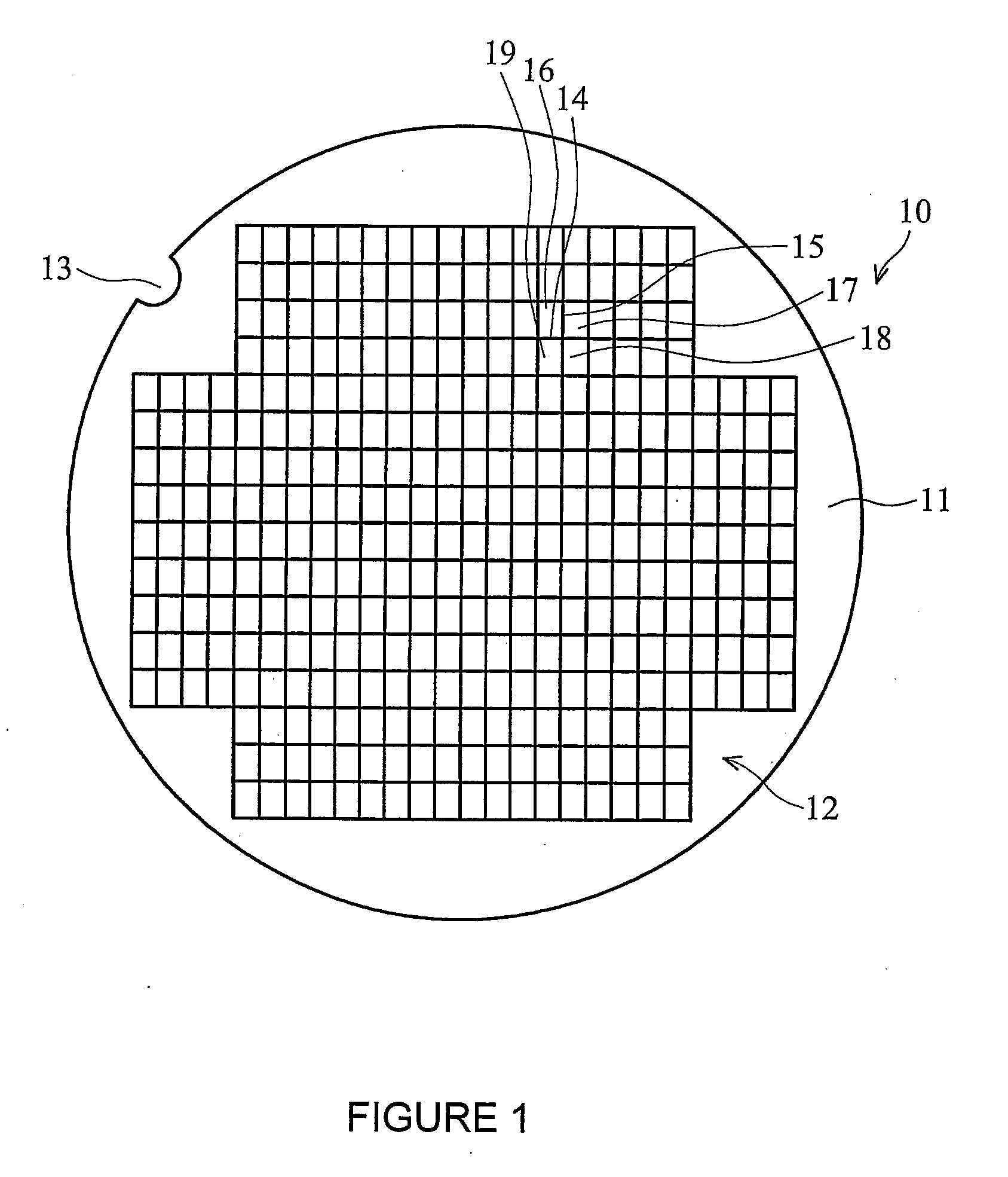

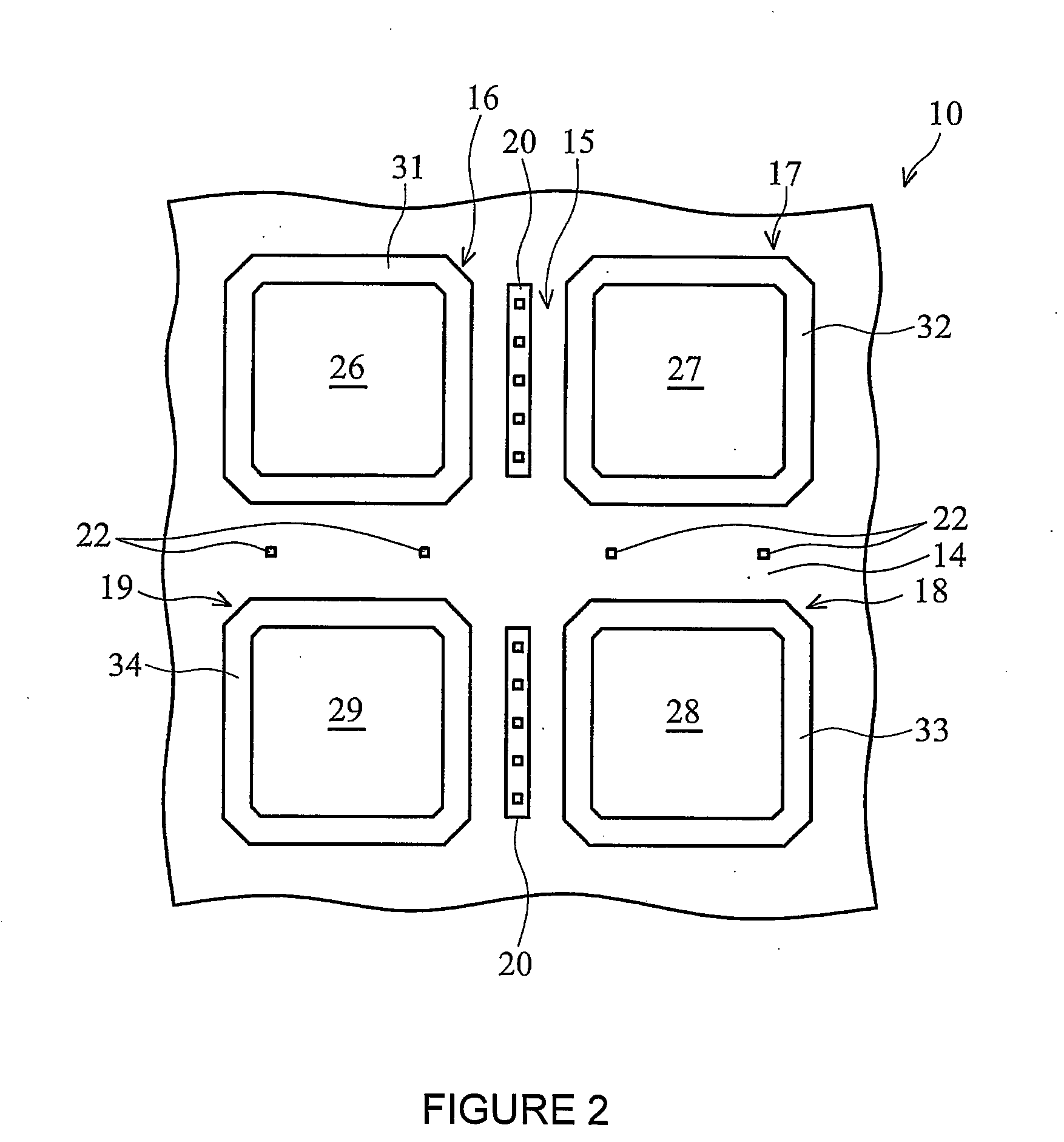

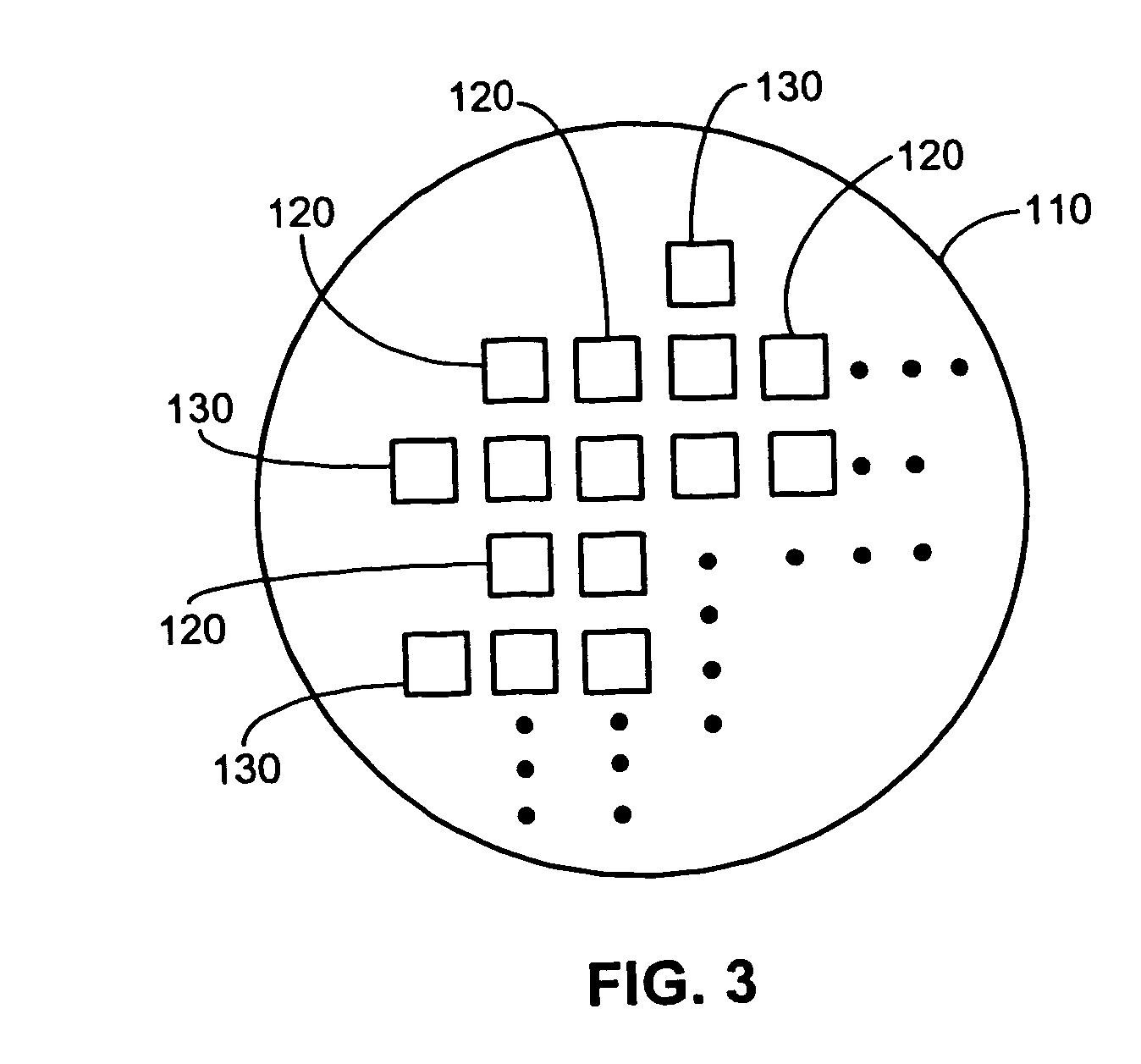

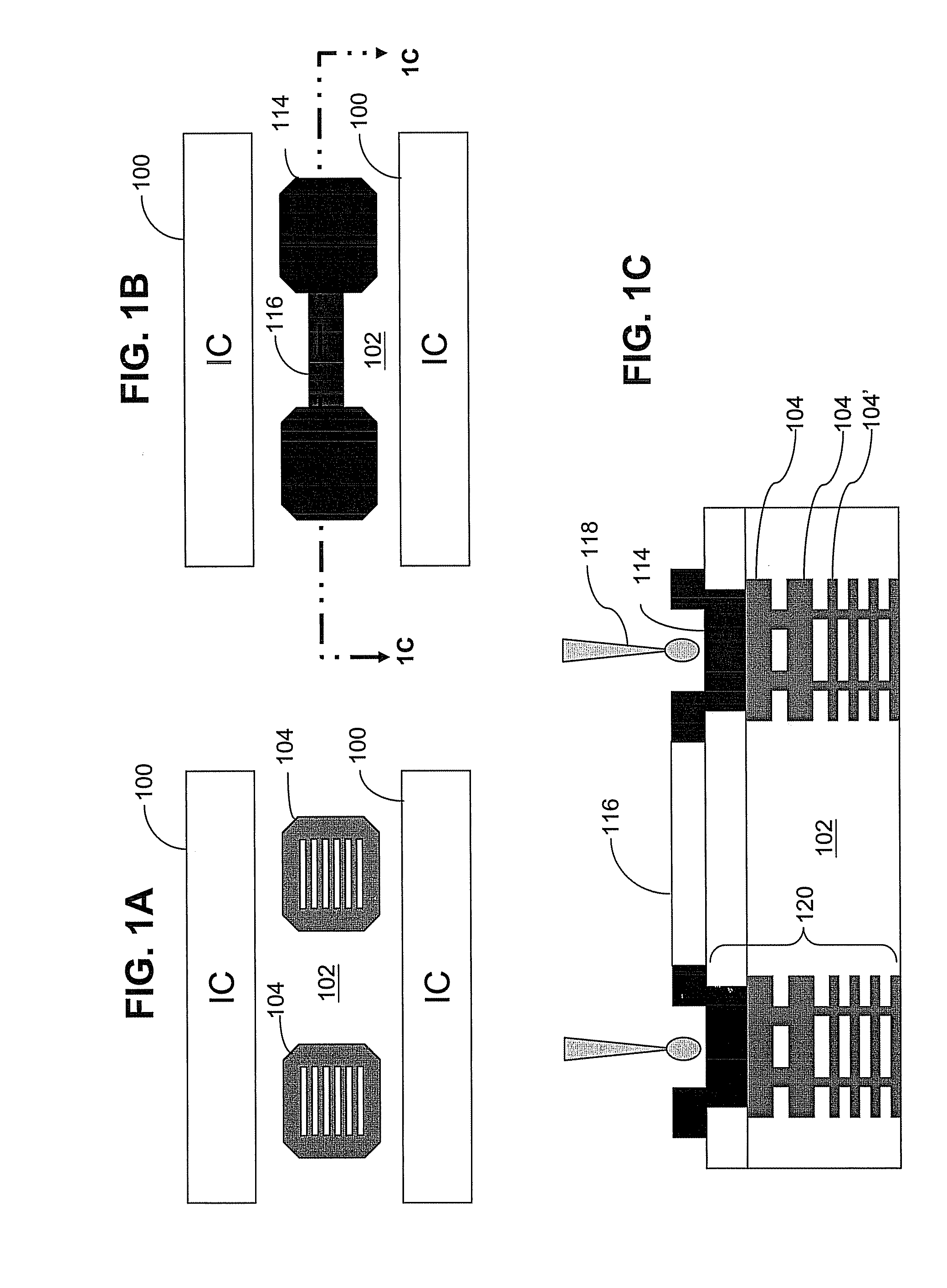

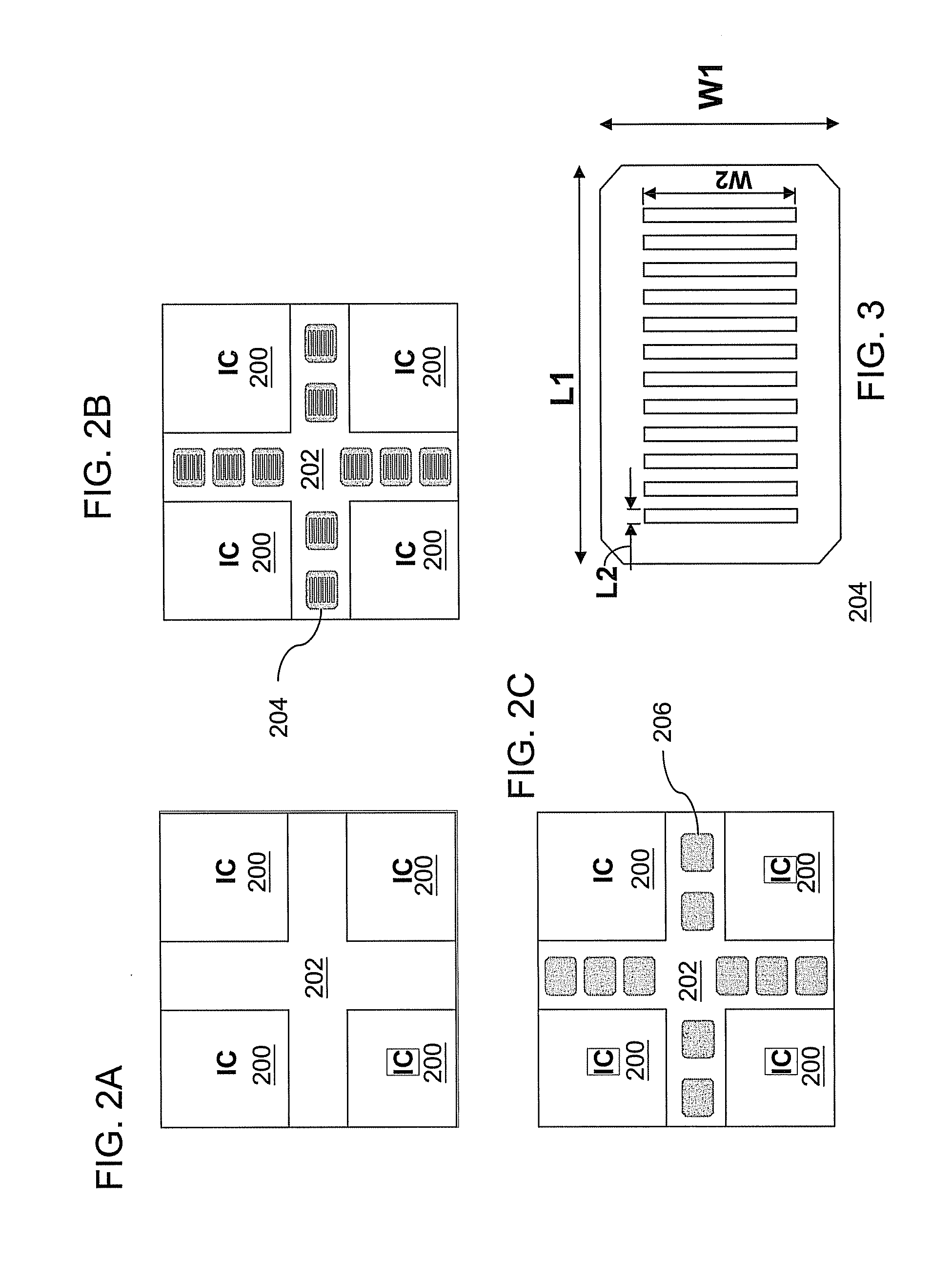

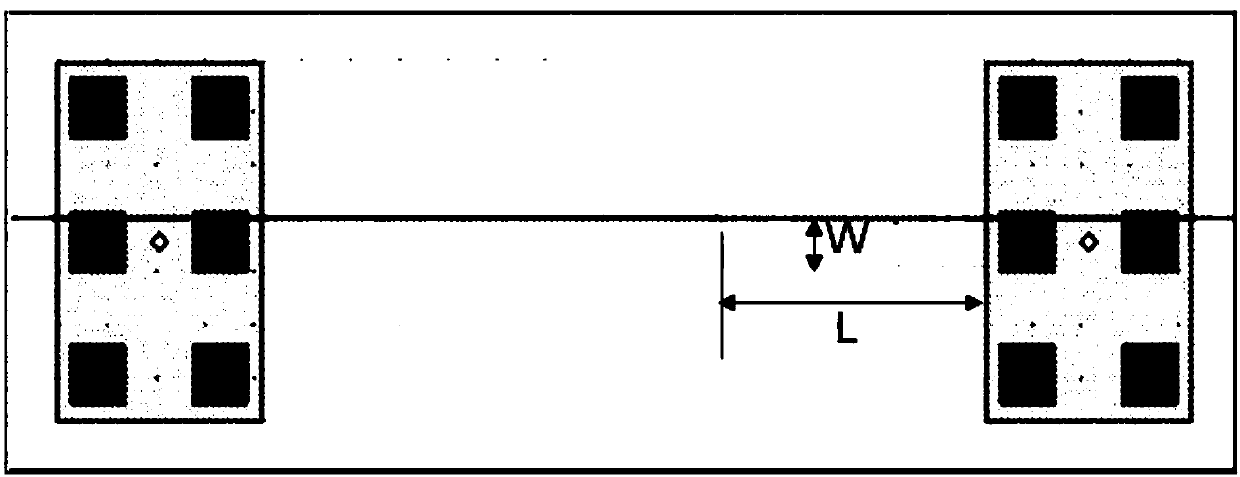

A test structure for use in a semiconductor chip. In a preferred embodiment, a number of die are formed in an array on a semiconductor wafer substrate. Each die includes an active area defined by a seal ring and is separated from those adjacent to it by a thin scribe line. In addition to the operational structures formed in the active area of each die, one or more test structures are formed. In a preferred embodiment, these test structures are formed into one or more PCM (process control monitor) test pattern layout areas that are positioned near the seal ring and outside of the operational bond pads. Some or all of individual pads in the PCM test pattern layout area may then be connected to corresponding features on adjacent dice, and in some applications enable the simultaneous performance of WAT (wafer acceptance test) and CP (circuit probe) testing.

Owner:TAIWAN SEMICON MFG CO LTD

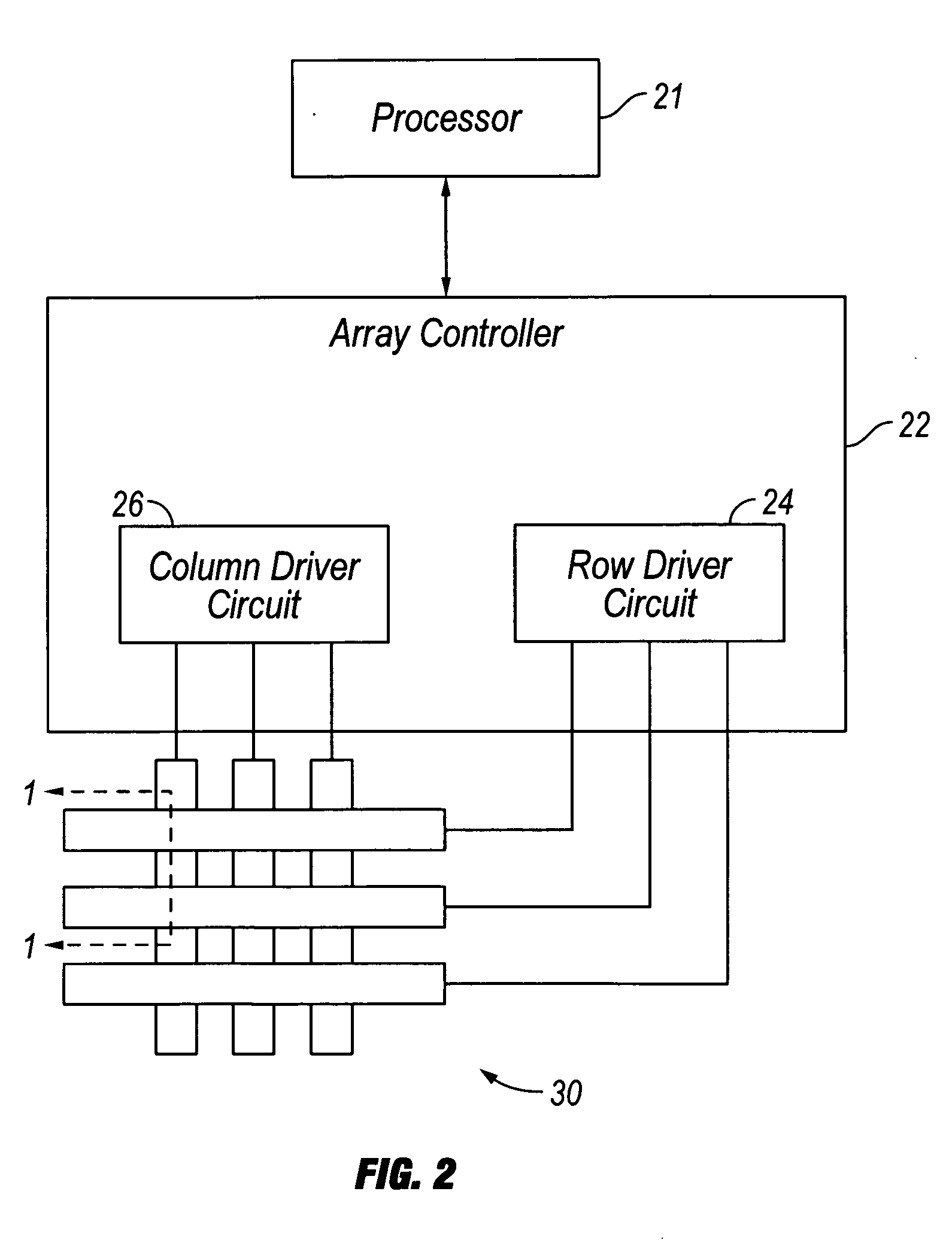

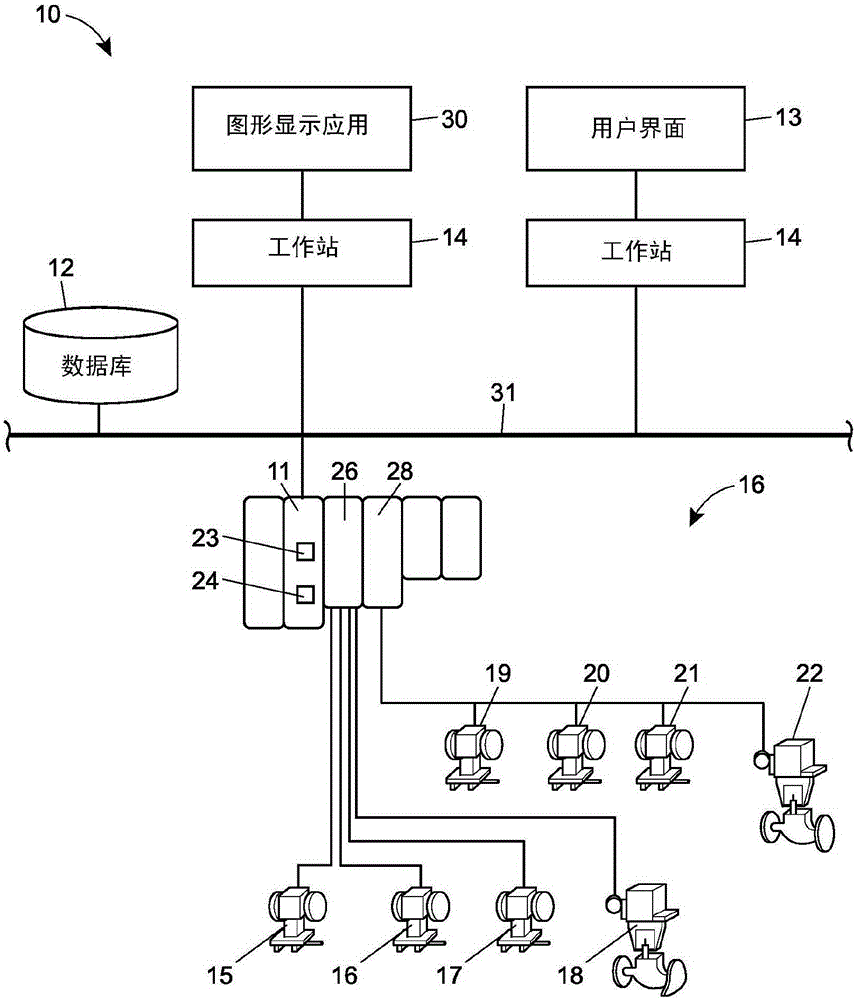

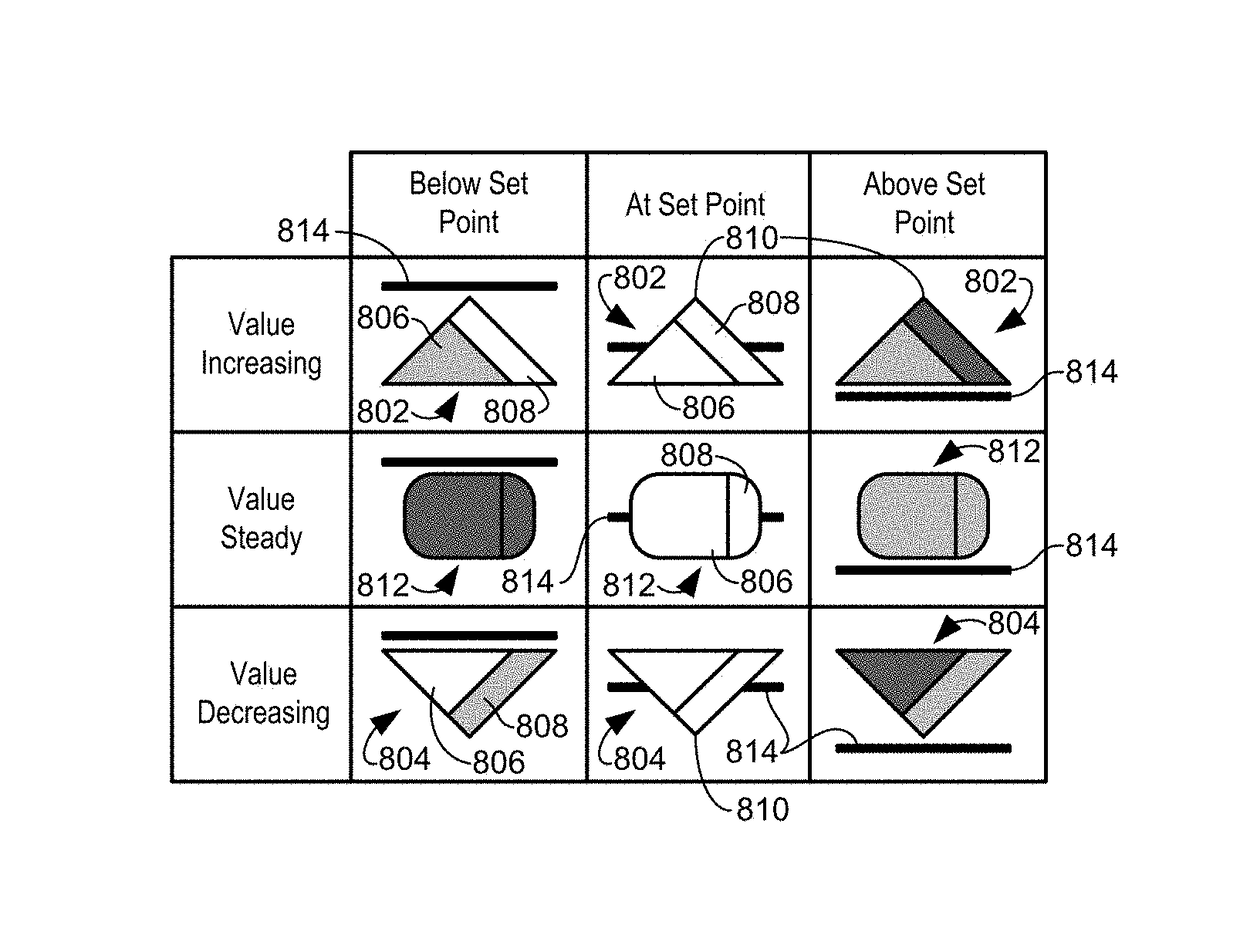

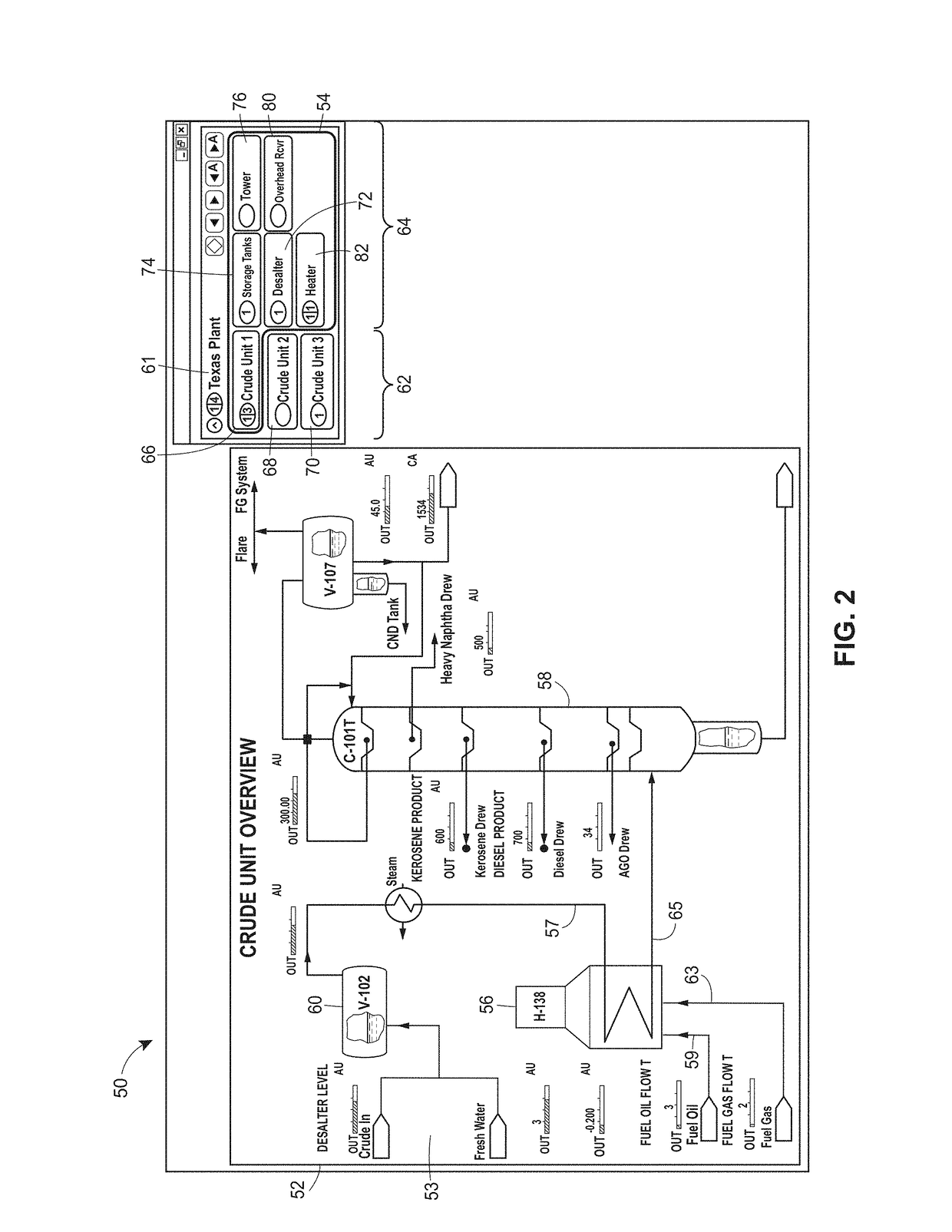

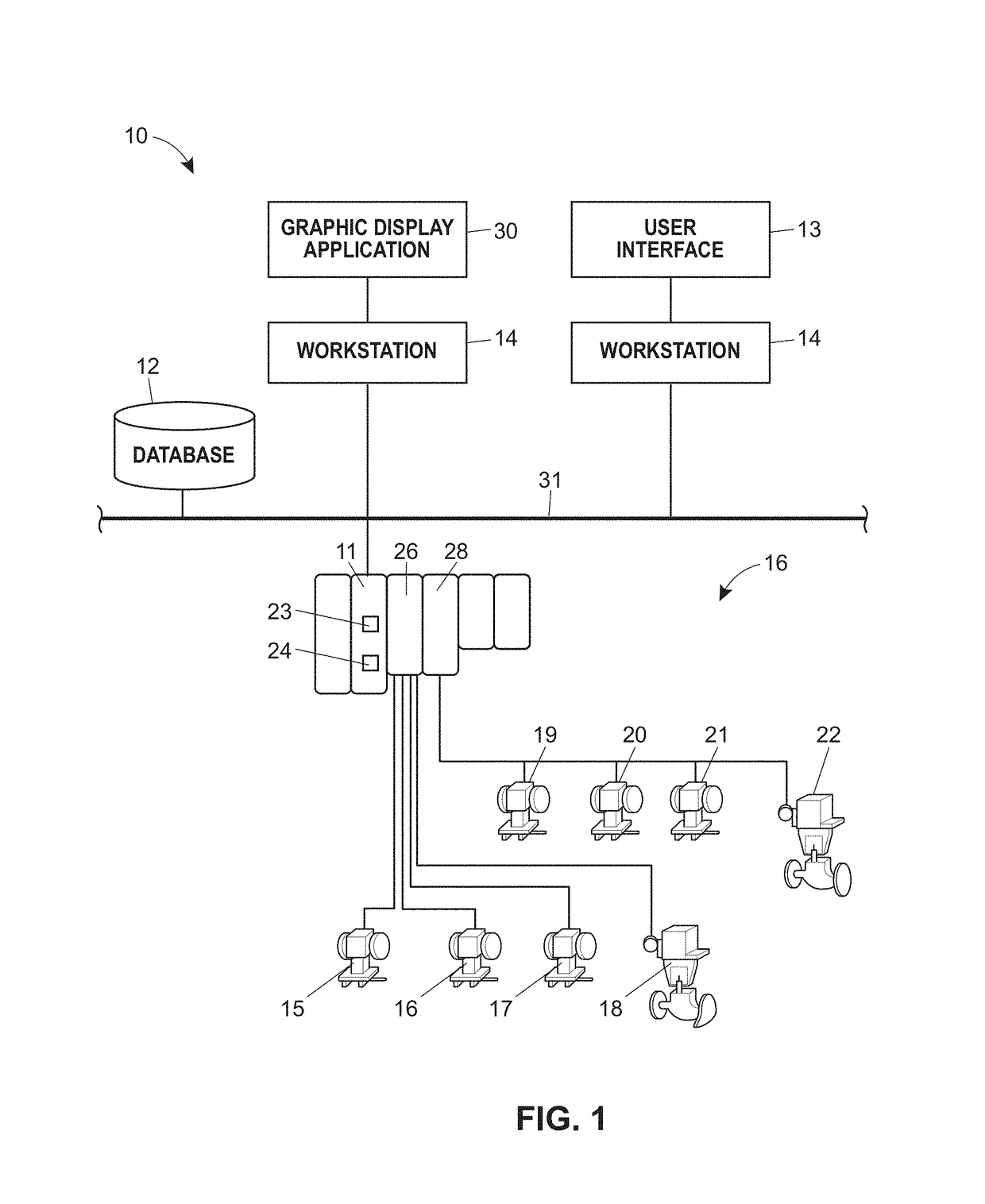

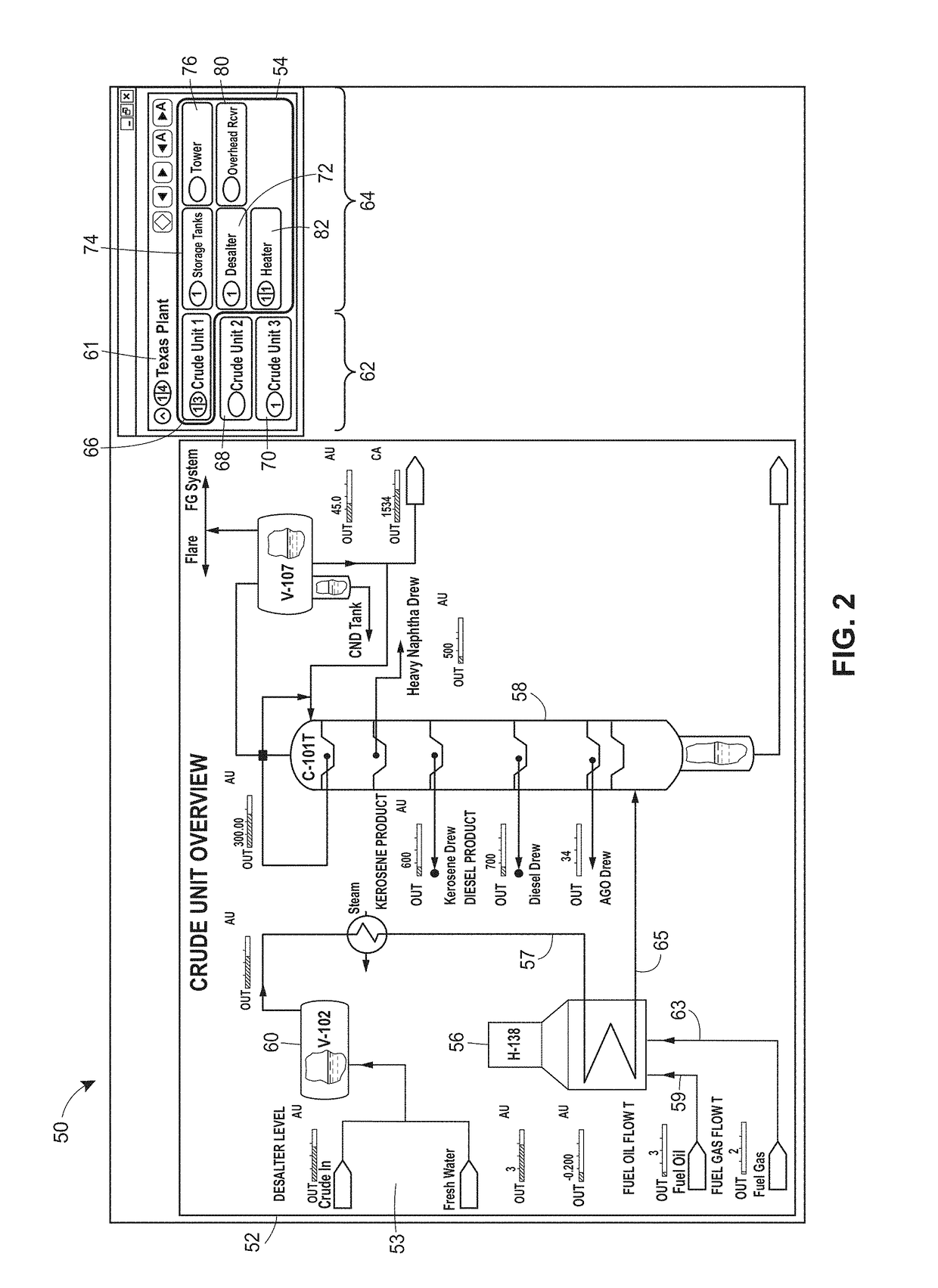

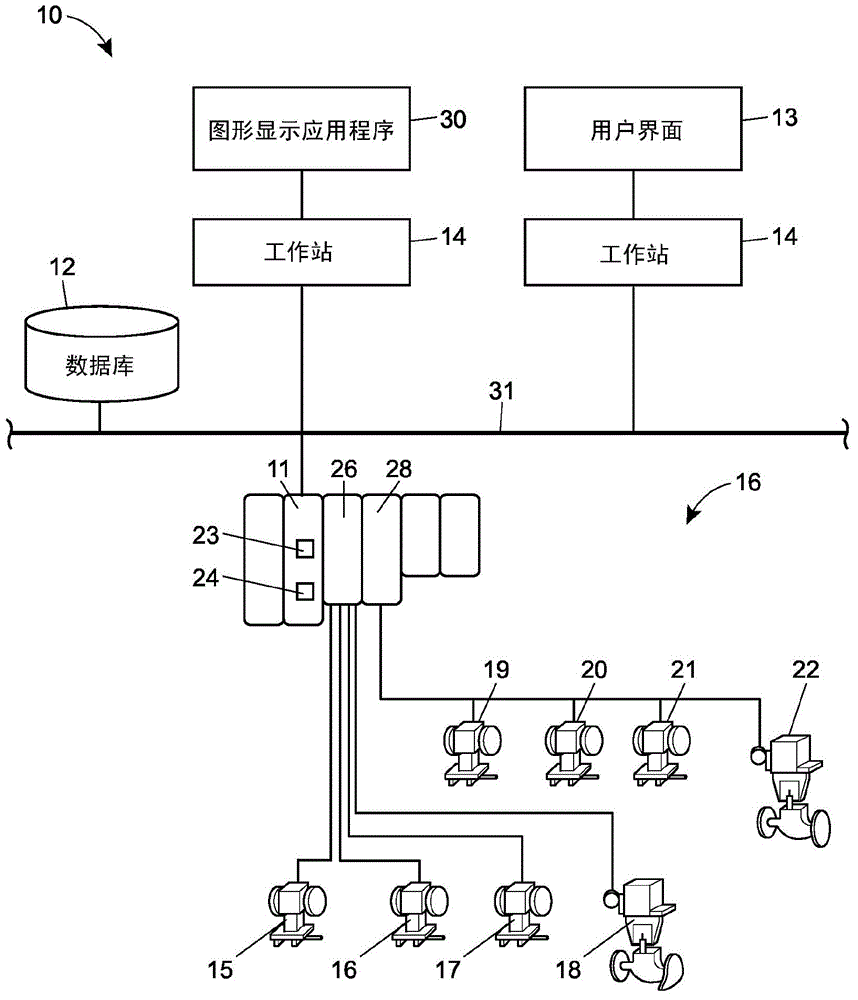

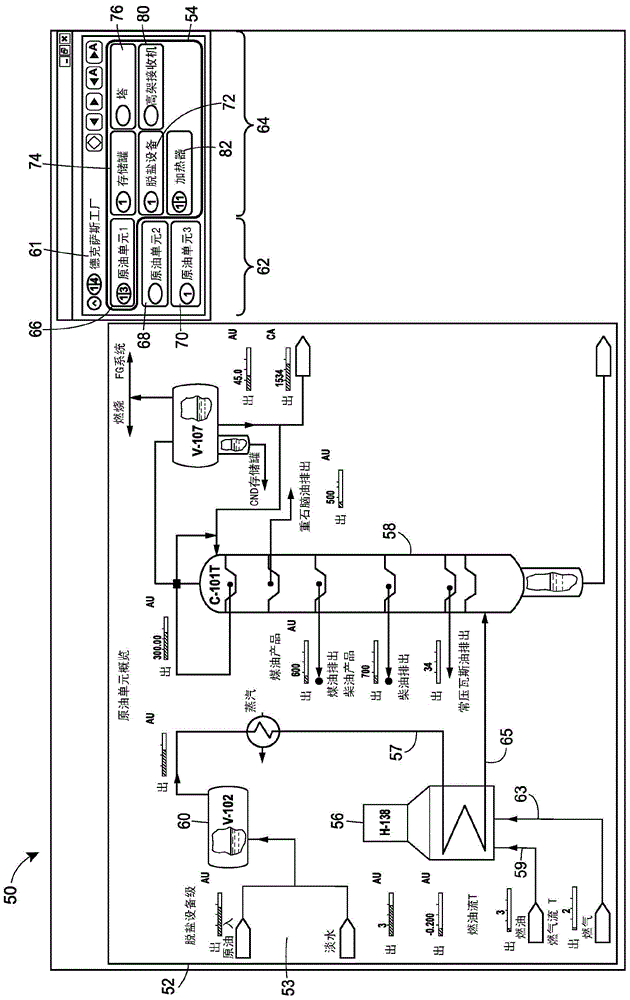

Graphical Process Variable Trend Monitoring for a Process Control System

ActiveUS20140282195A1Assist in detectingEasy to distinguishTesting/monitoring control systemsInput/output processes for data processingGraphicsDrill down

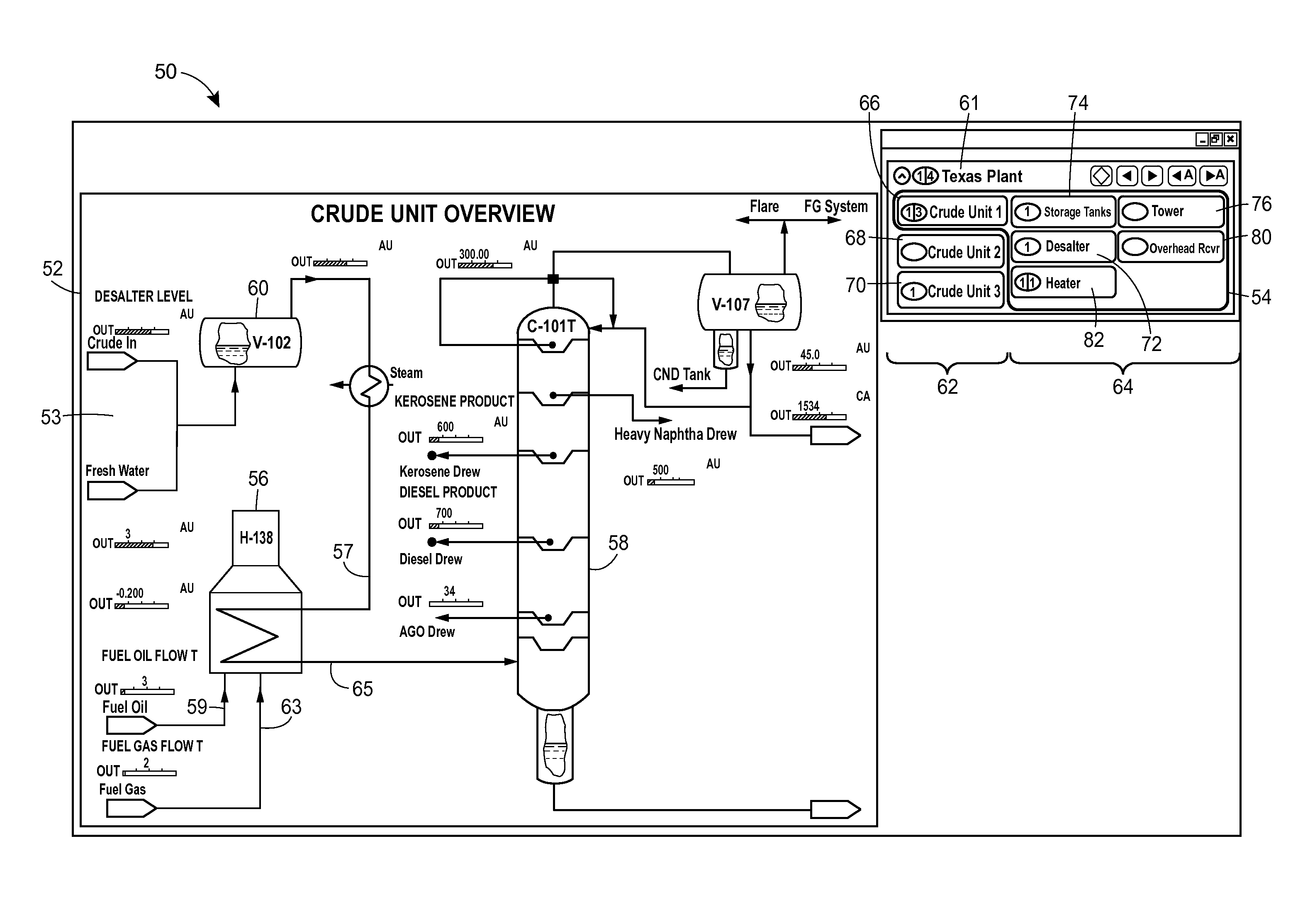

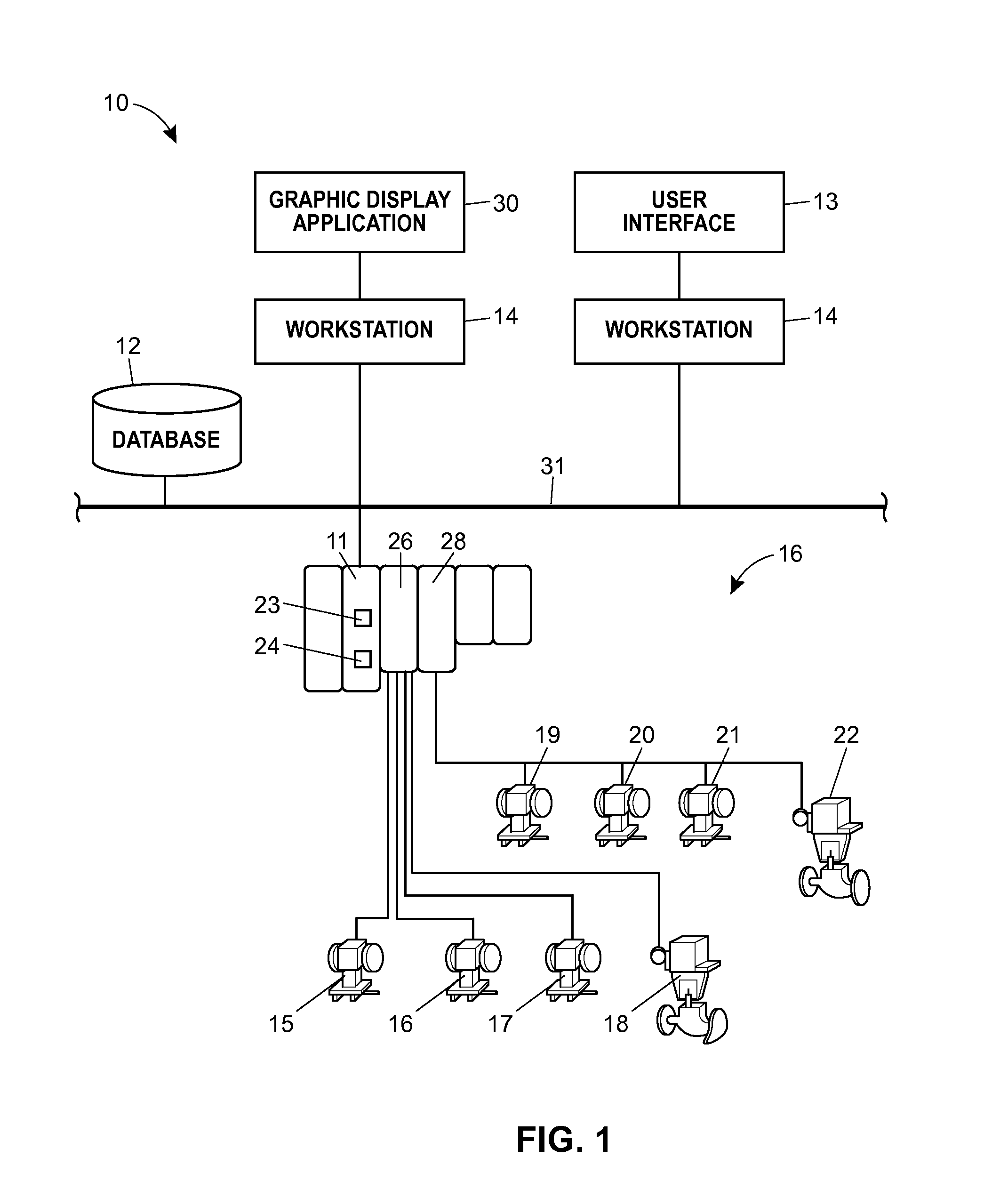

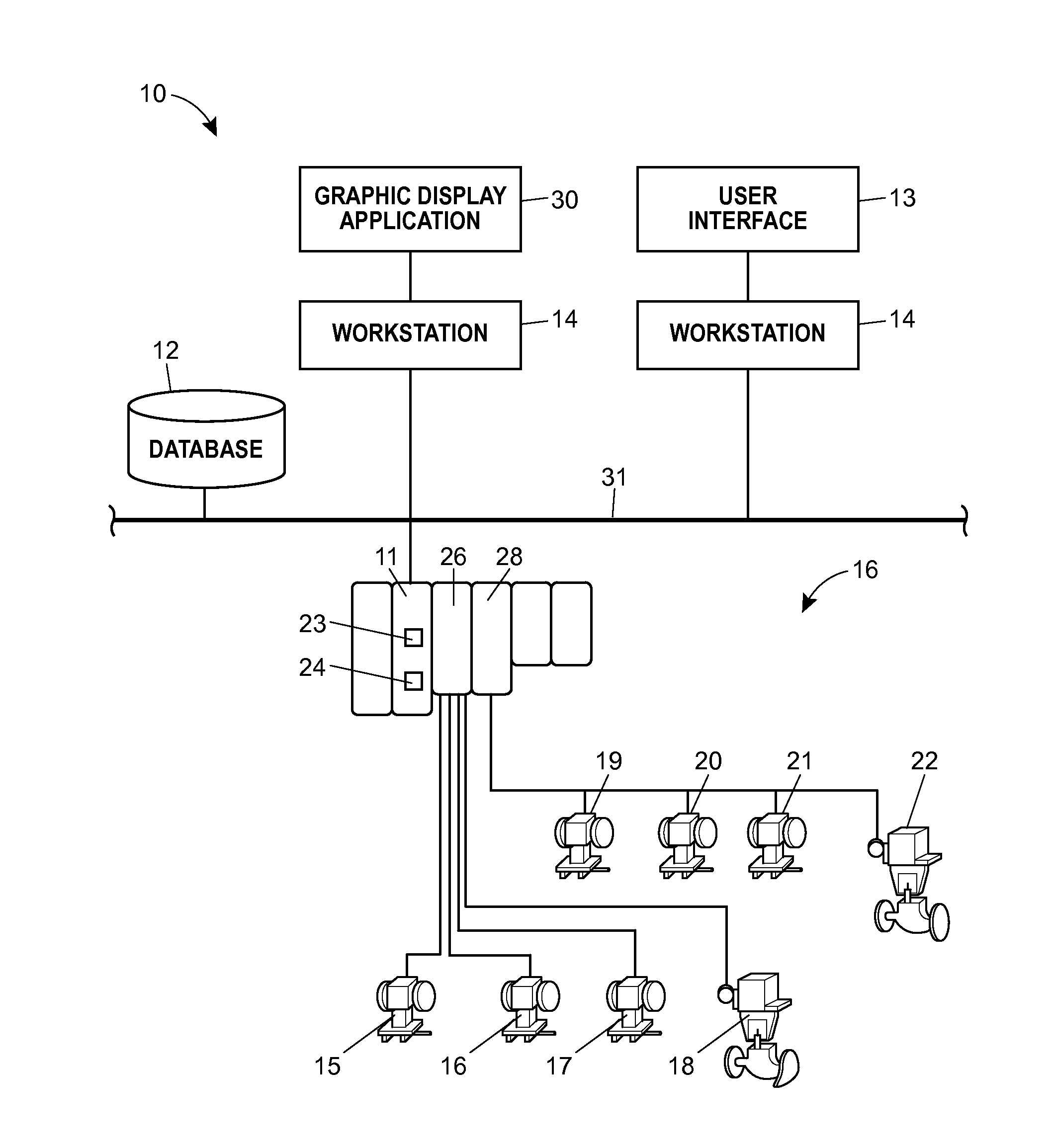

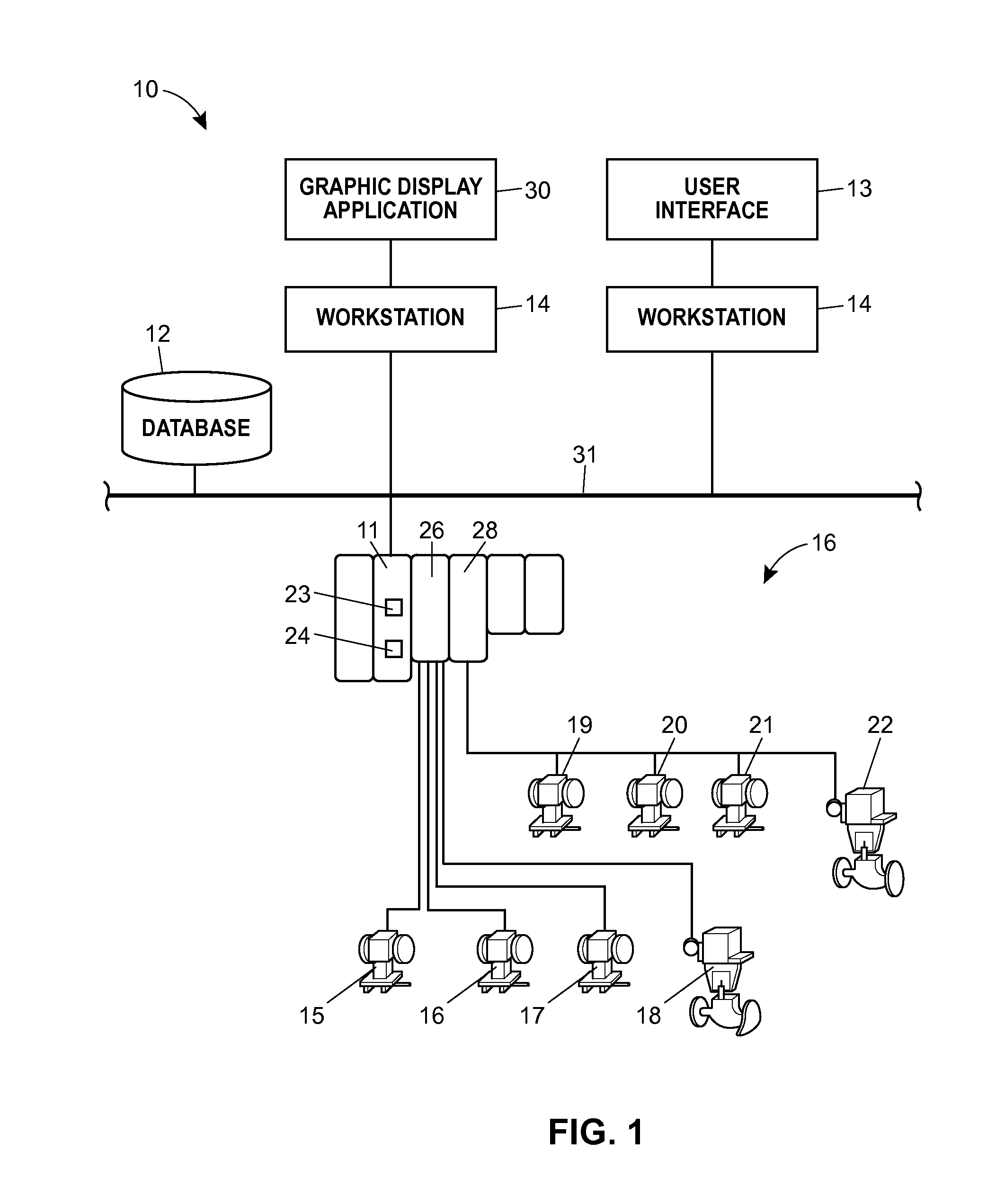

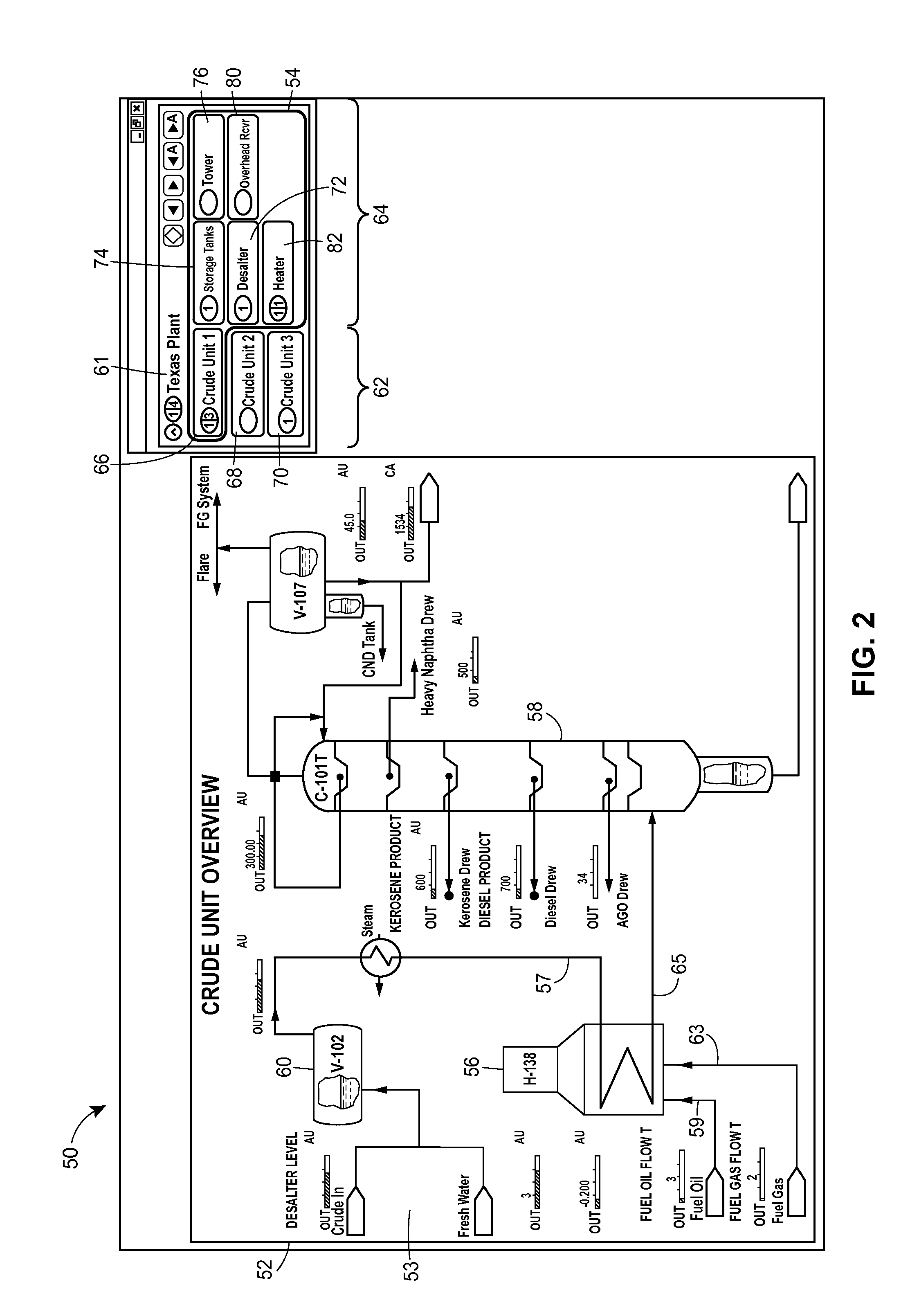

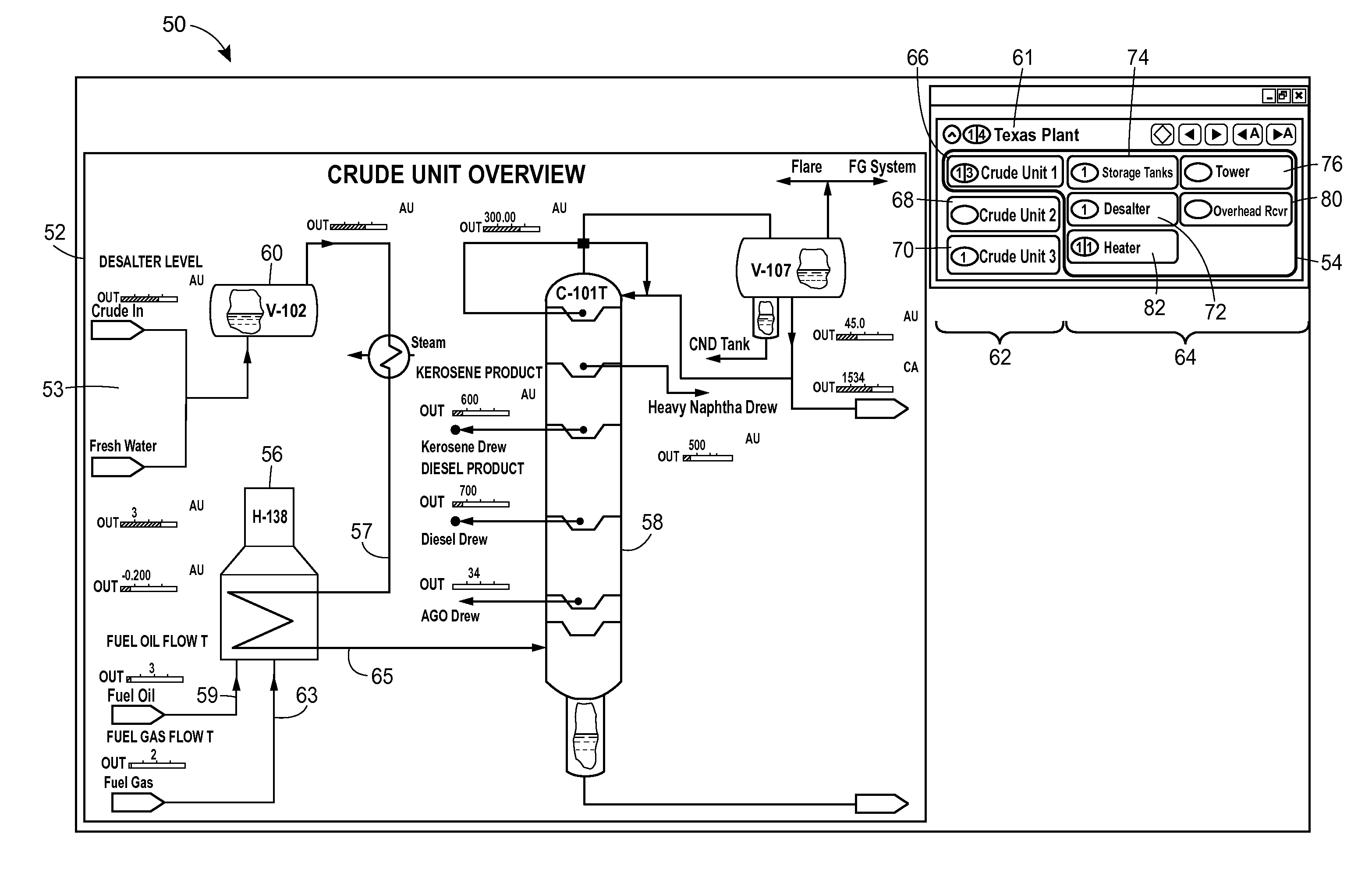

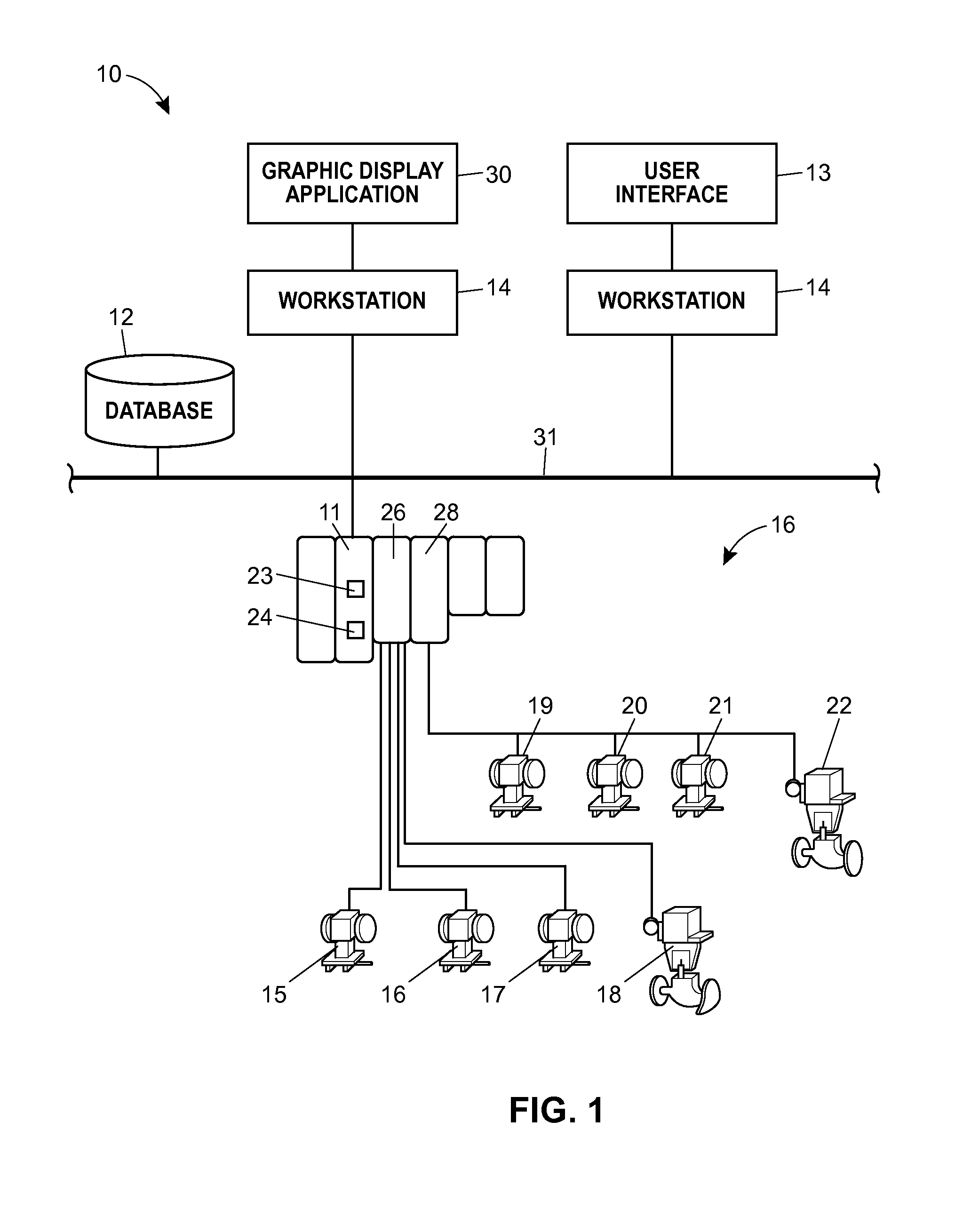

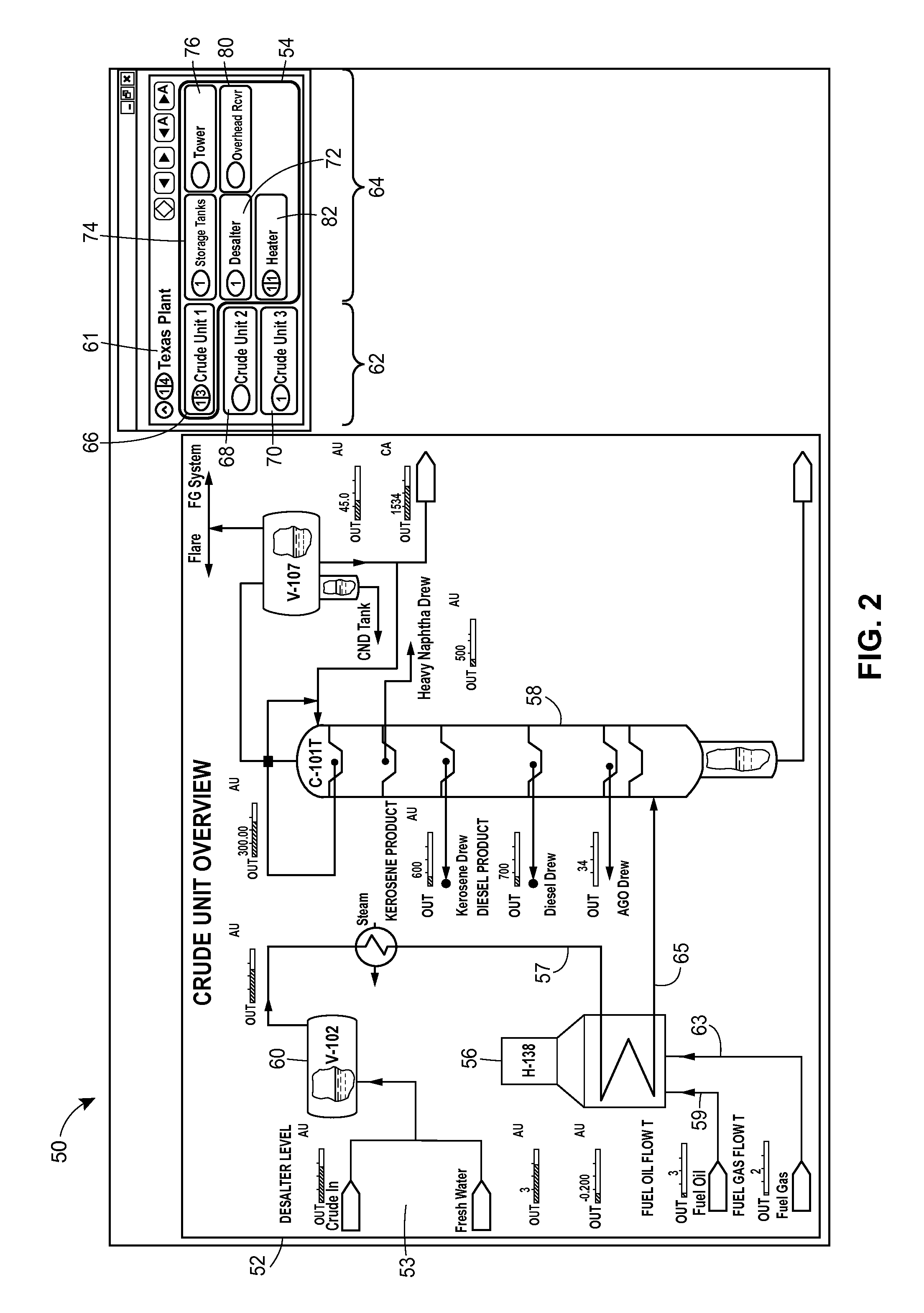

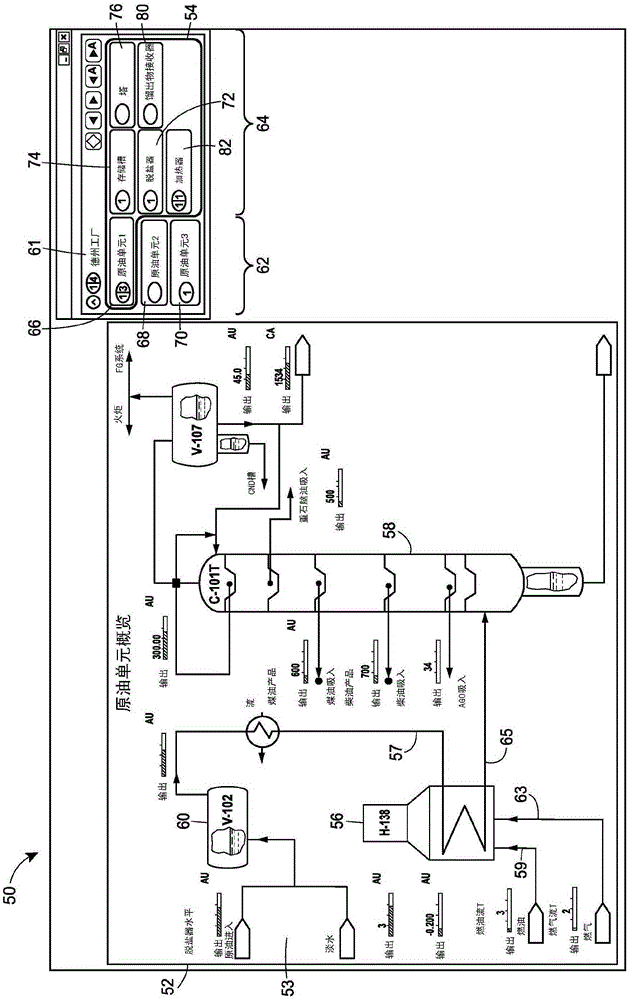

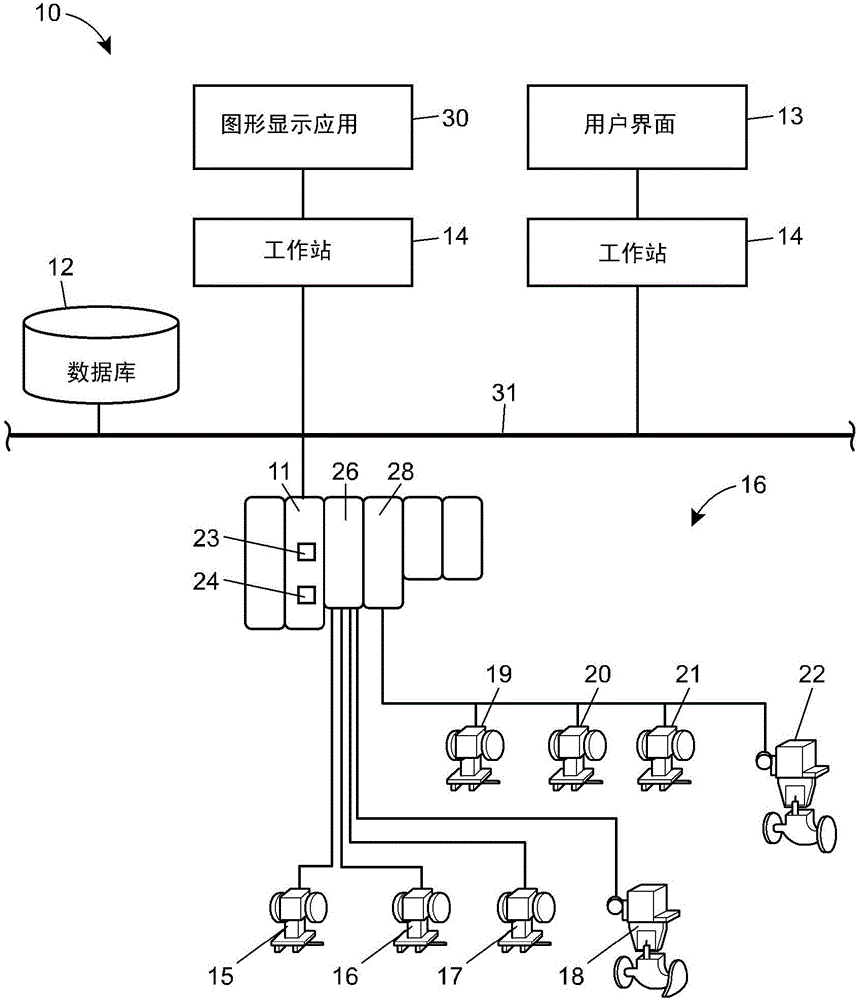

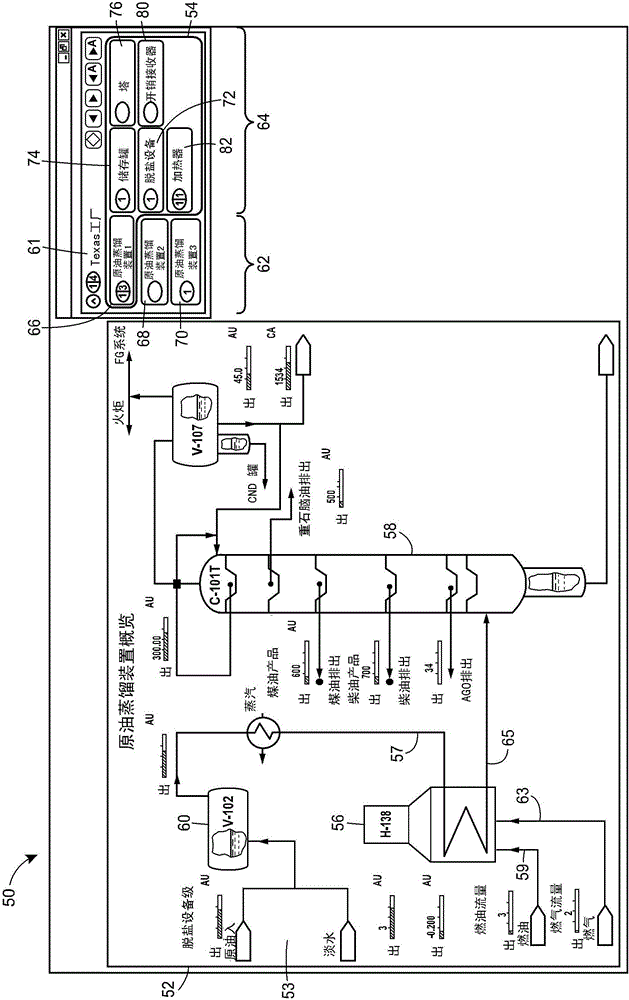

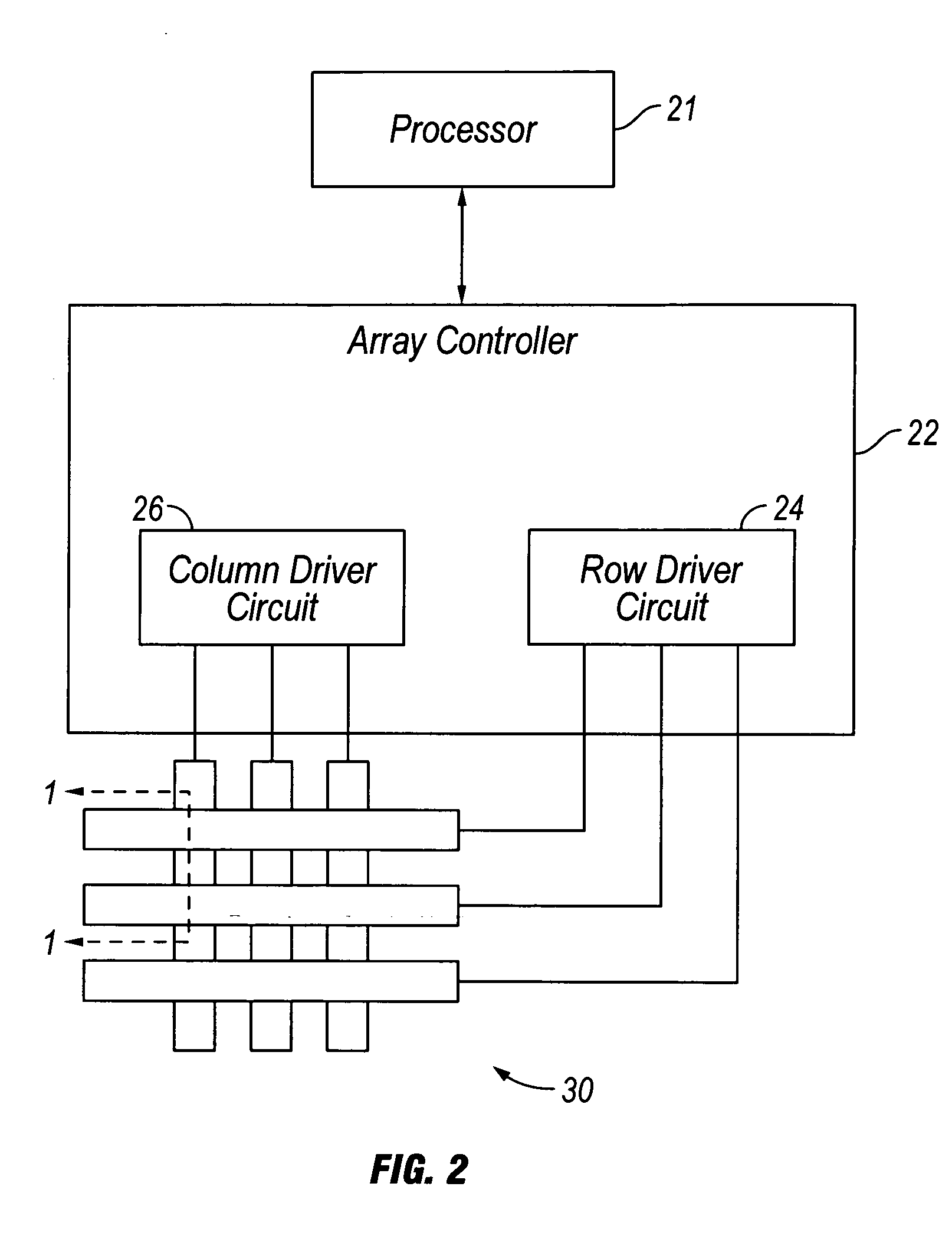

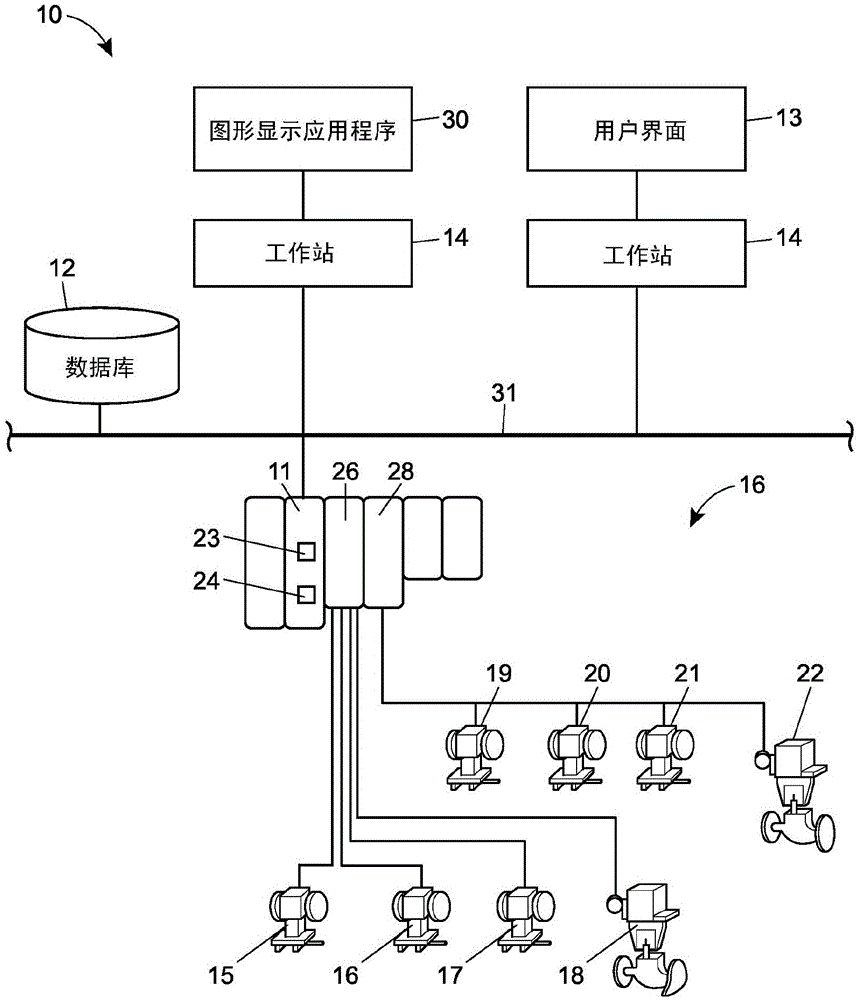

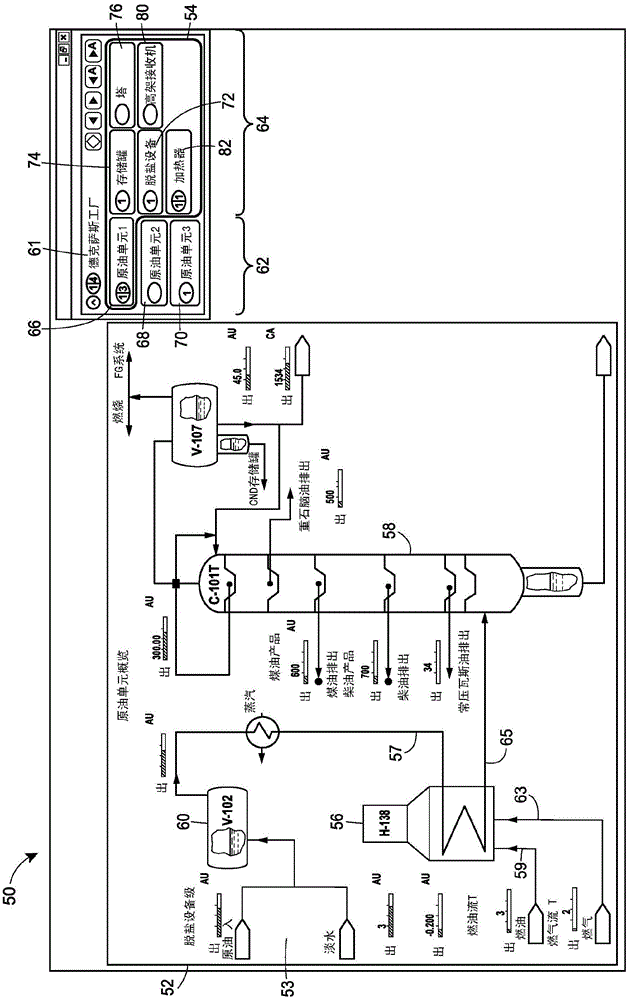

A process control monitoring system for a process control plant uses graphic trend symbols to assist in detecting and monitoring trends of process variables within the process control plant. A graphic display application within the process control monitoring system may implement and display each graphic trend symbol to graphically indicate or encapsulate current trend and value information of a process variable within the process control plant. The graphic display application may display the graphic trend symbol in a spatially realistic location within a graphical representation of the process control plant while maintaining the hierarchical structure or each hierarchical level of the process plant. The graphic display application may also include a zoom feature that enables a user to quickly drill down through tend data to obtain more information and to support problem identification and diagnosis tasks.

Owner:FISHER-ROSEMOUNT SYST INC

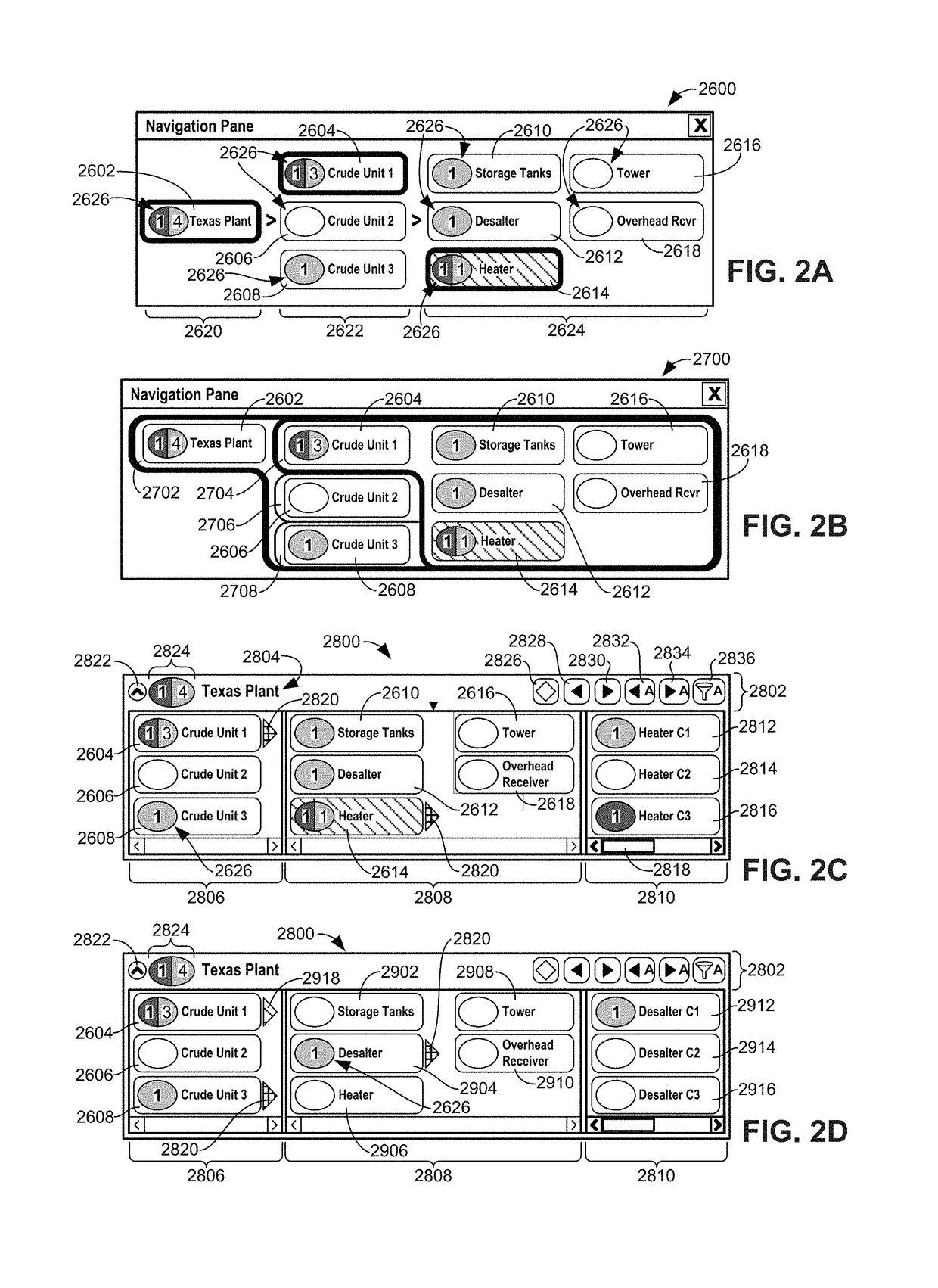

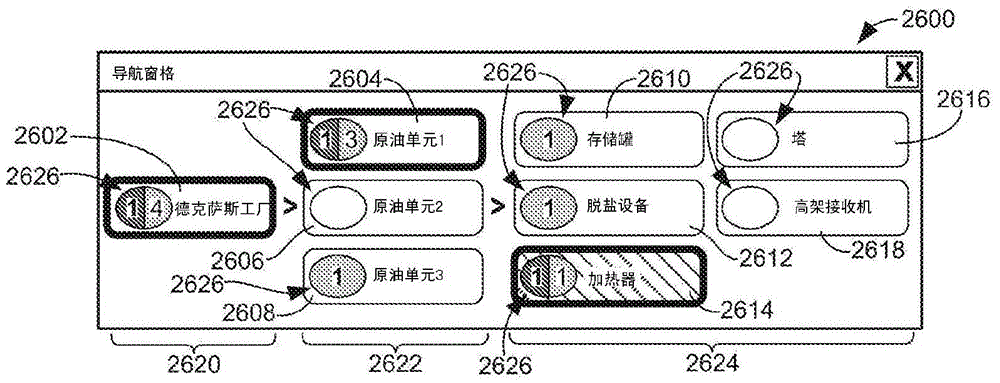

Graphical Process Variable Trend Monitoring, Predictive Analytics and Fault Detection in a Process Control System

ActiveUS20160042541A1Assist in detectingEasy to distinguishDrawing from basic elementsTesting/monitoring control systemsProblem identificationTrend monitoring

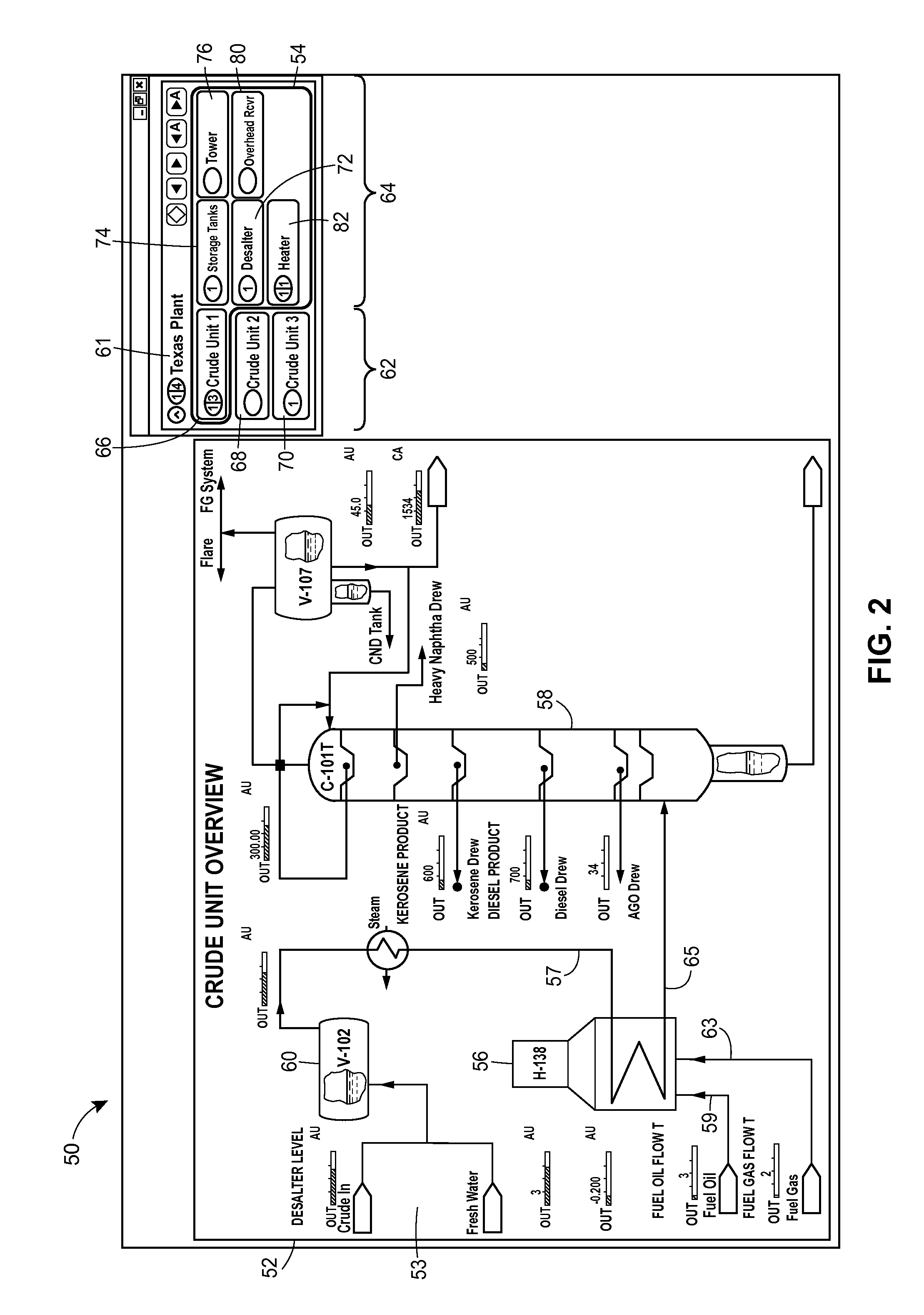

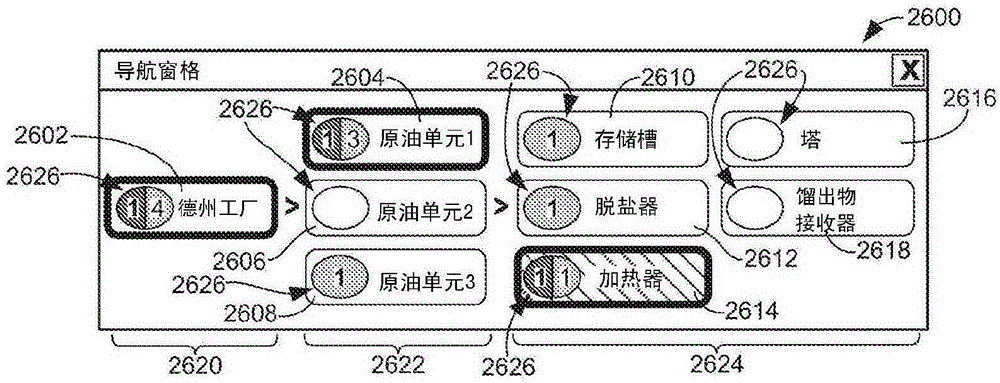

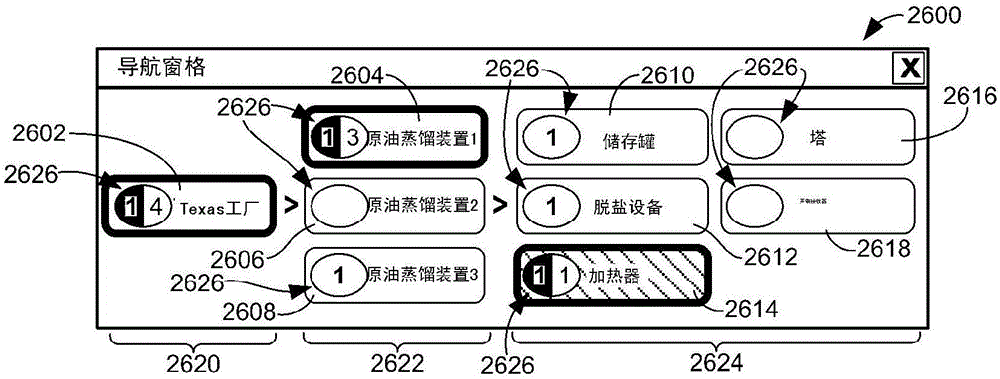

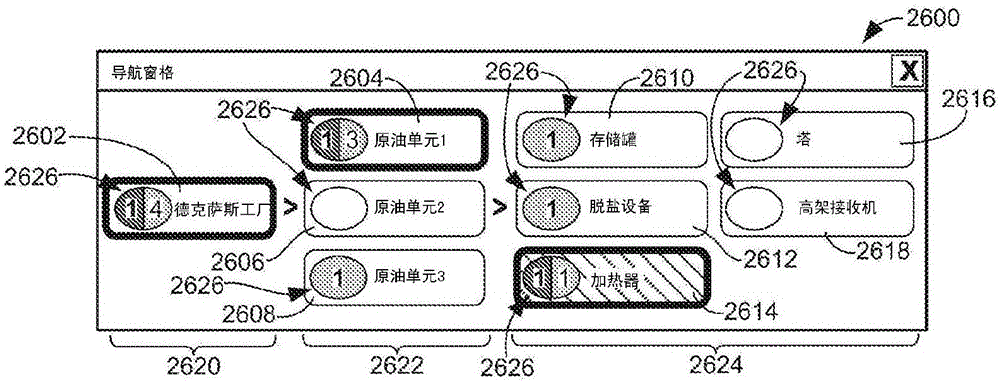

A process control monitoring system for a process control plant uses graphic trend symbols to assist in detecting and monitoring trends of process variables within the process control plant. A graphic display application within the process control monitoring system may implement and display each graphic trend symbol to graphically indicate or encapsulate current trend and value information of a process variable within the process control plant. The graphic display application may display the graphic trend symbol in a spatially realistic location within a graphical representation of the process control plant while maintaining the hierarchical structure or each hierarchical level of the process plant. The graphic display application may also include a navigation pane and a zoom feature that enable a user to quickly drill down through tend data to obtain more information and to support problem identification and diagnosis tasks.

Owner:FISHER-ROSEMOUNT SYST INC

Graphical process variable trend monitoring in a process control system using a navigation pane

ActiveUS20140277619A1Assist in detectingEasy to distinguishProgramme controlComputer controlGraphicsDrill down

A process control monitoring system for a process control plant uses graphic trend symbols to assist in detecting and monitoring trends of process variables within the process control plant. A graphic display application within the process control monitoring system may implement and display each graphic trend symbol to graphically indicate or encapsulate current trend and value information of a process variable within the process control plant. The graphic display application may display the graphic trend symbol in a spatially realistic location within a graphical representation of the process control plant while maintaining the hierarchical structure or each hierarchical level of the process plant. The graphic display application may also include a navigation pane and a zoom feature that enable a user to quickly drill down through tend data to obtain more information and to support problem identification and diagnosis tasks.

Owner:FISHER-ROSEMOUNT SYST INC

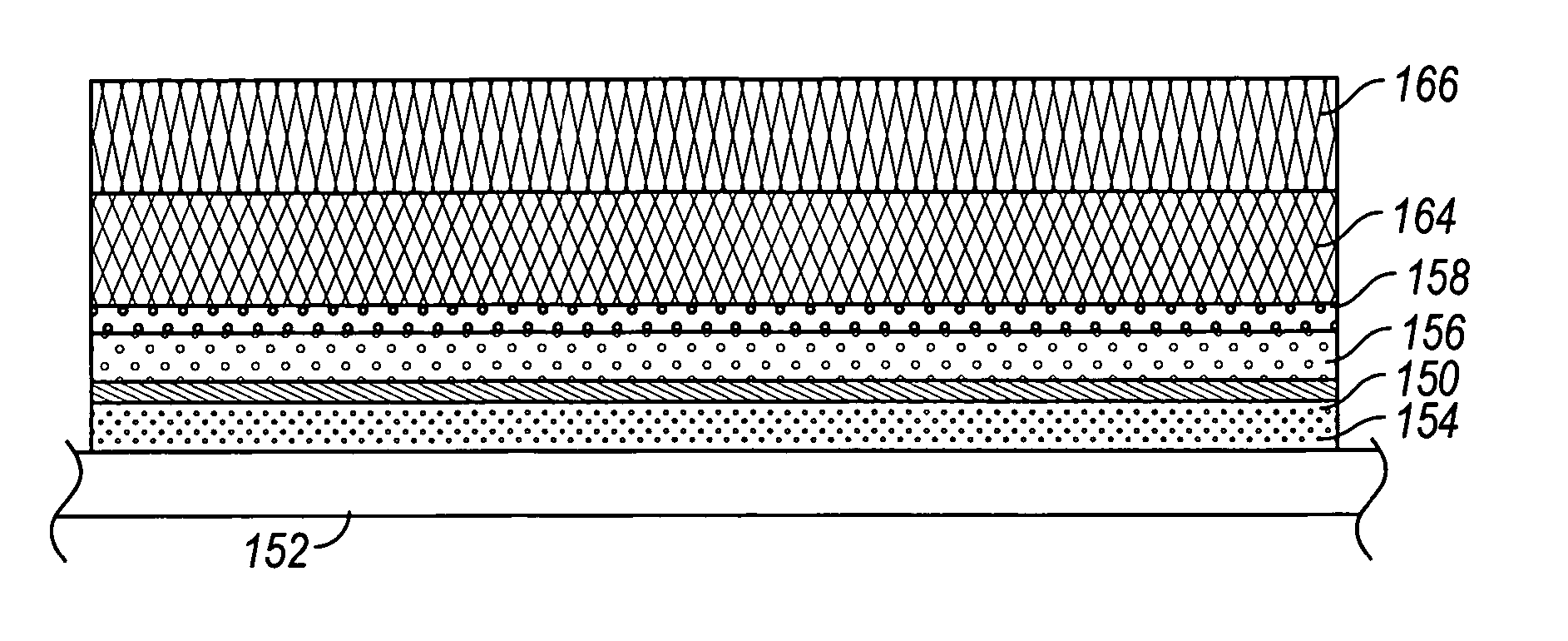

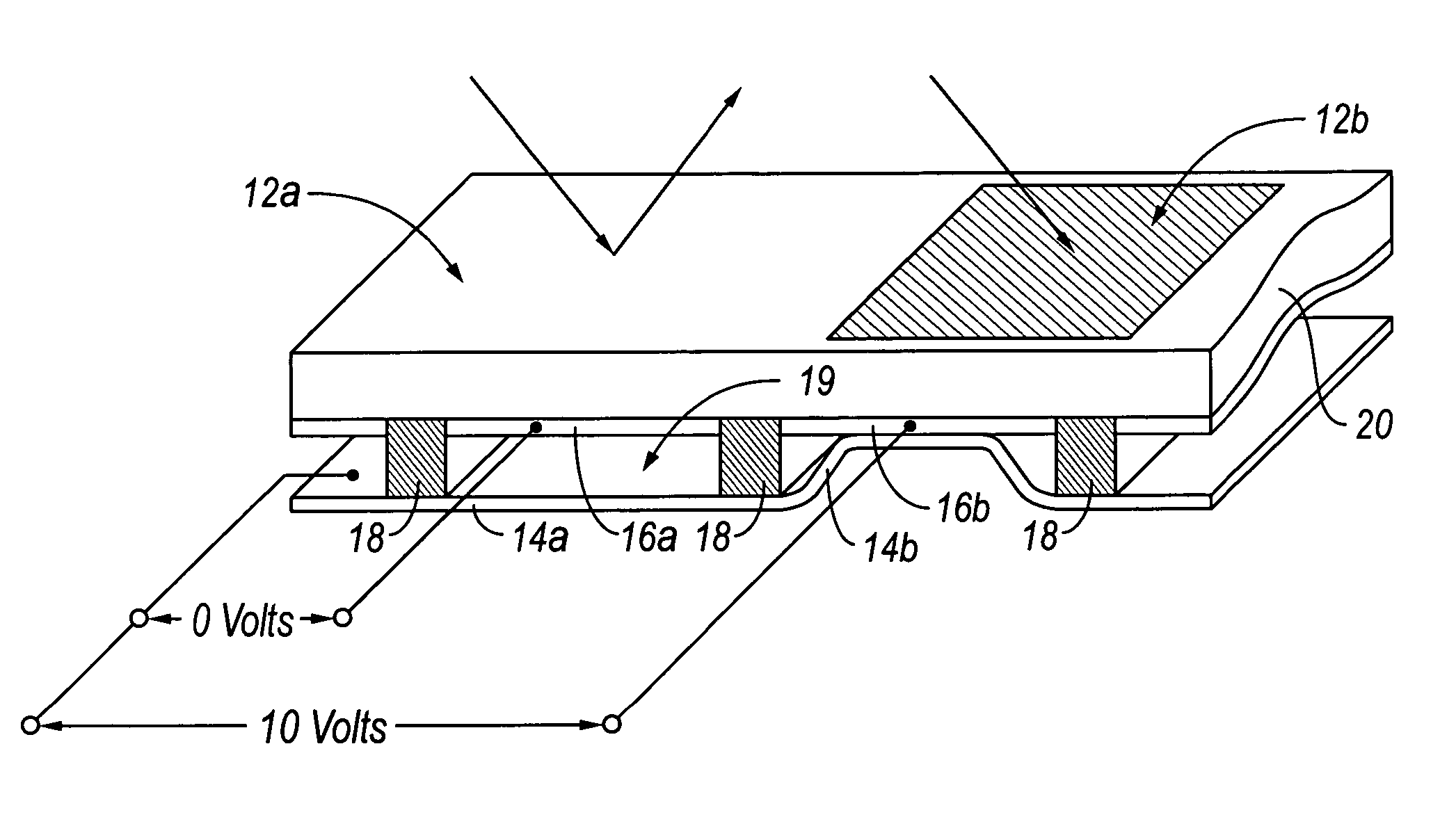

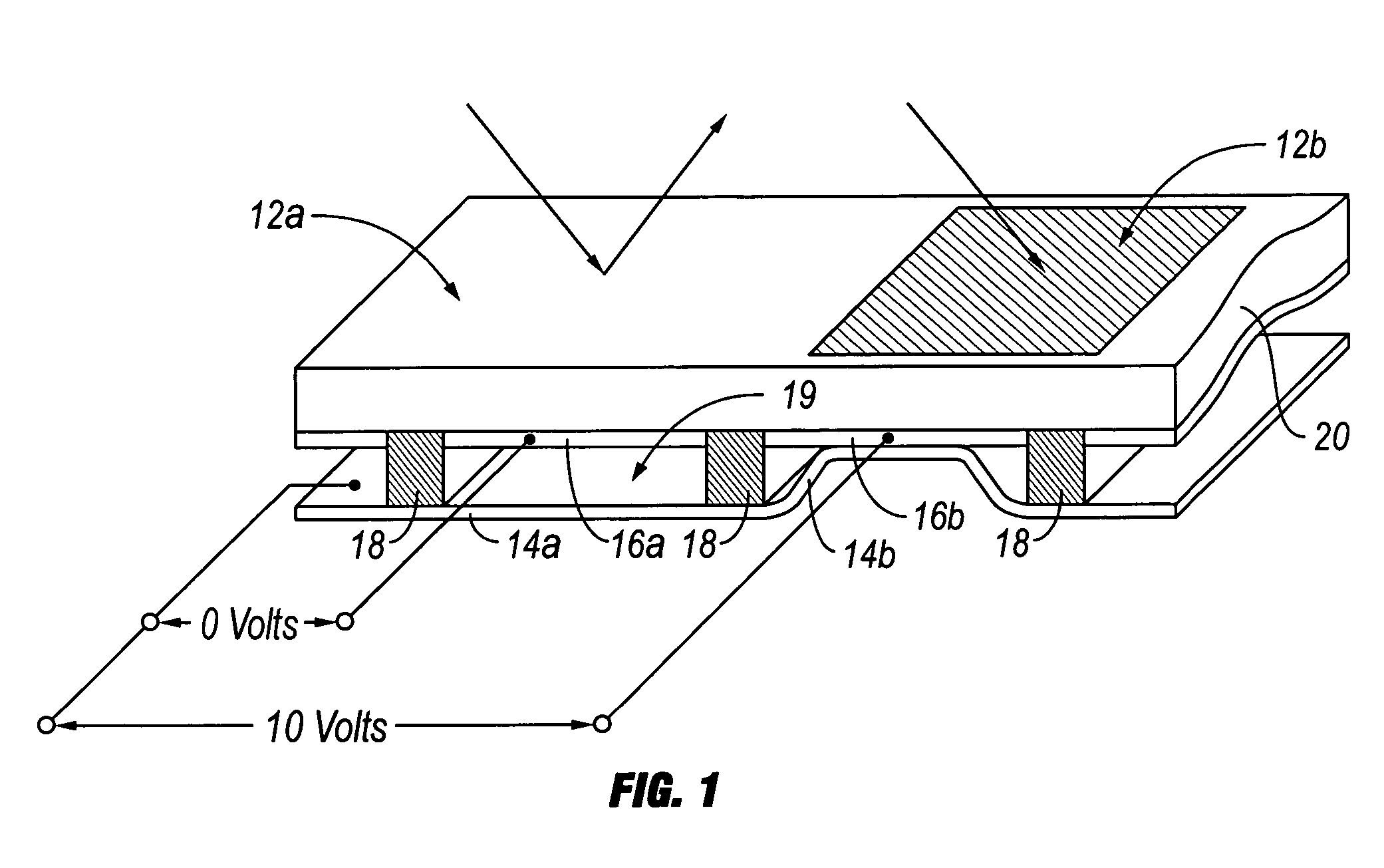

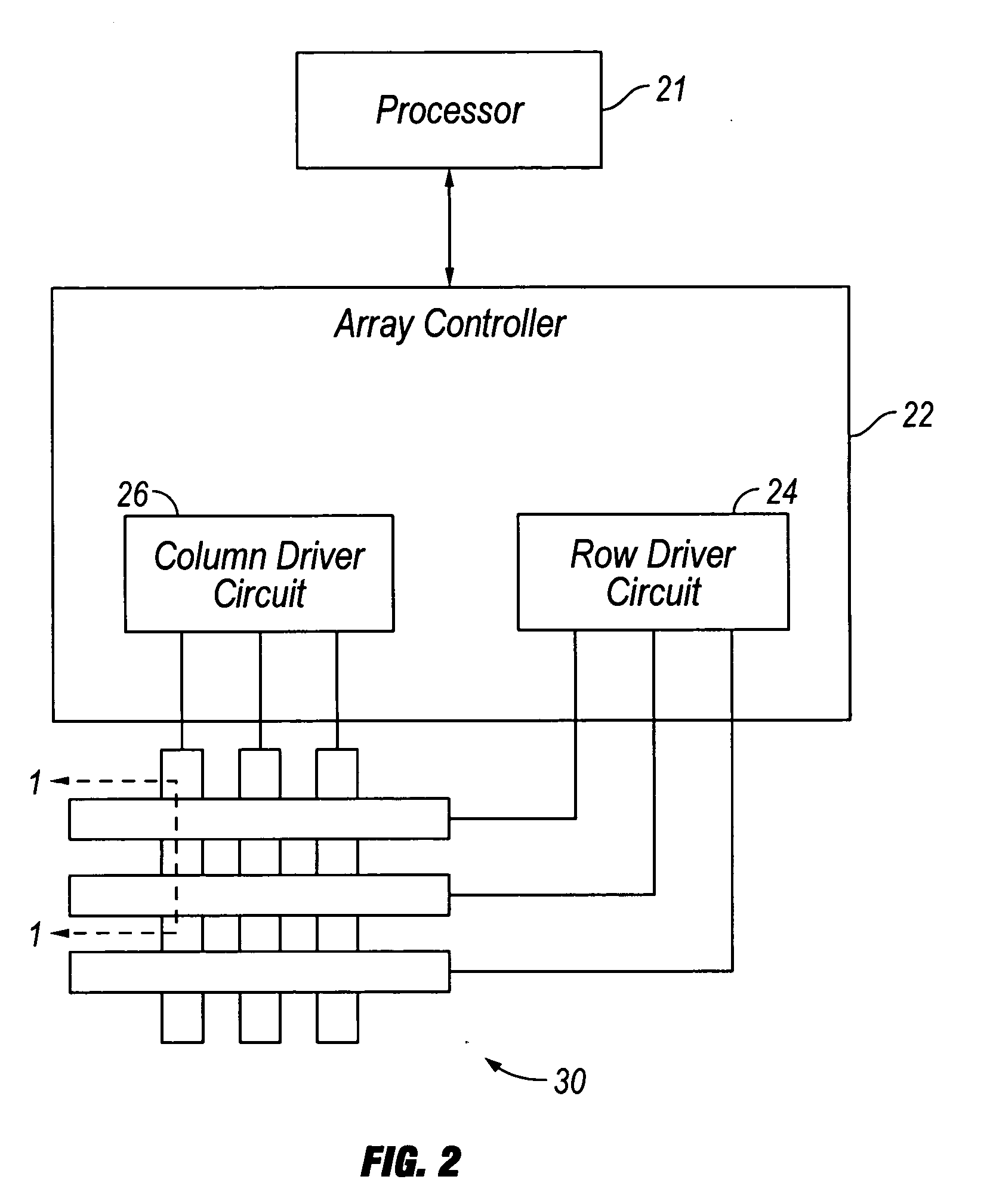

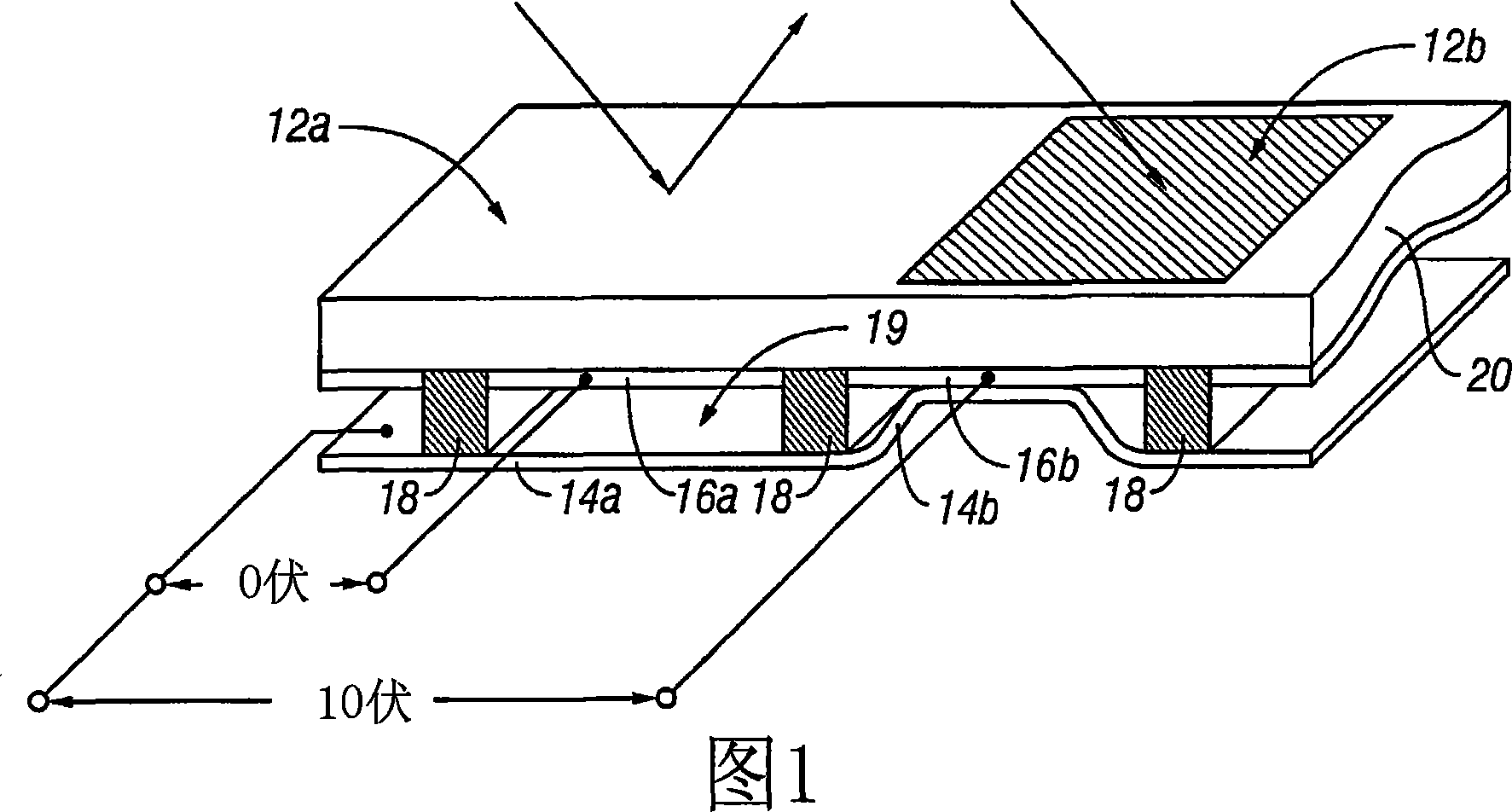

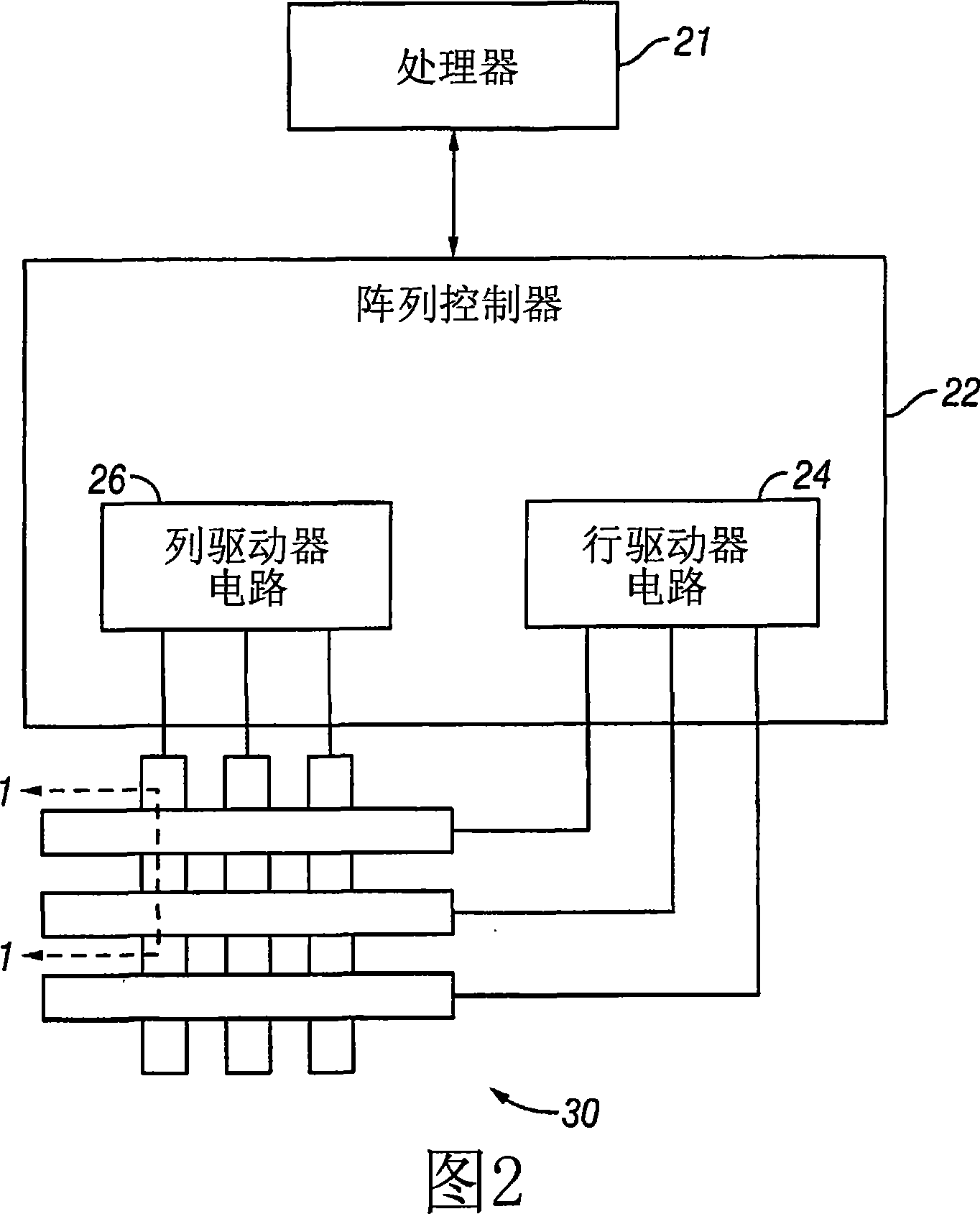

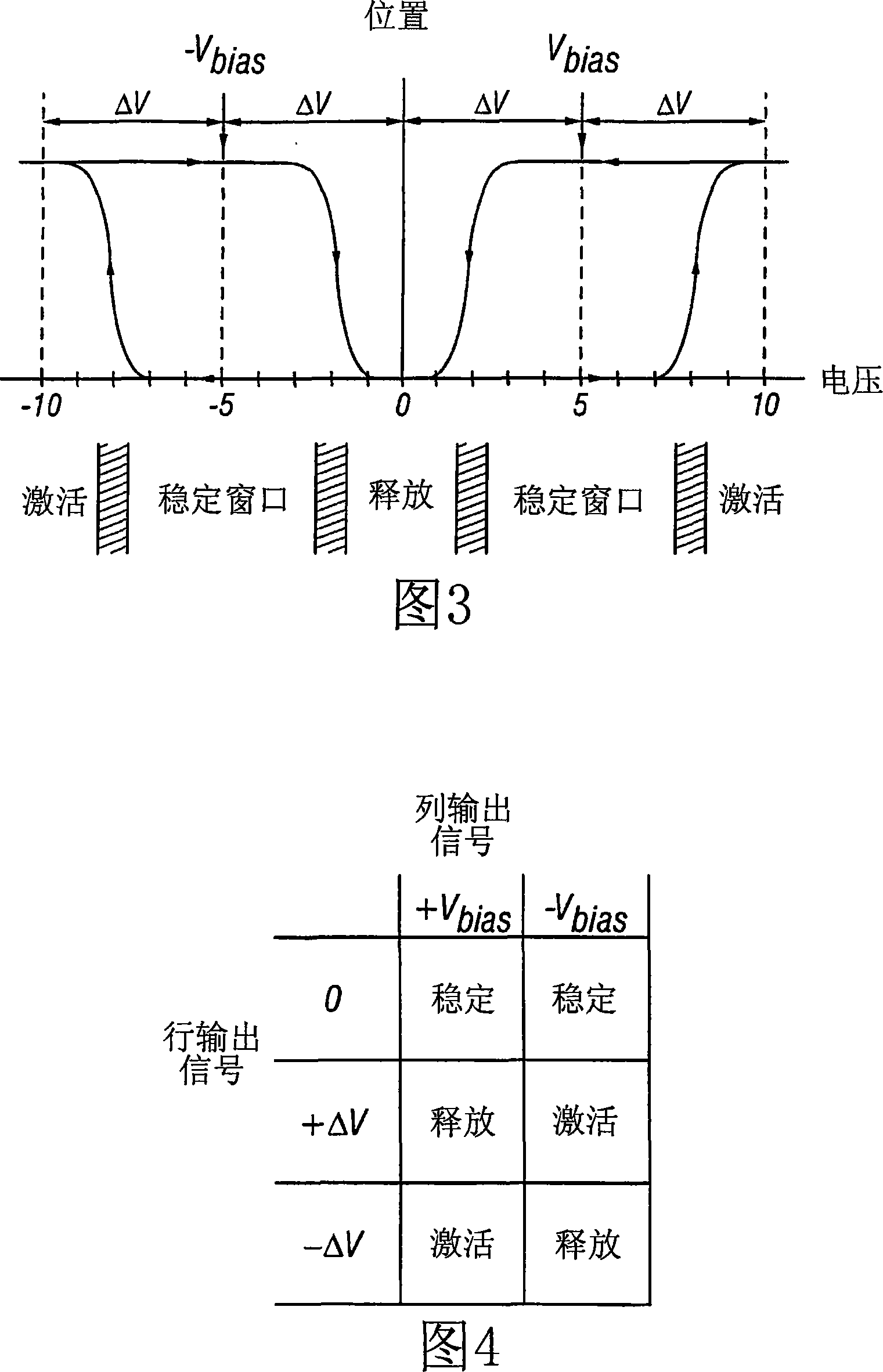

Process control monitors for interferometric modulators

InactiveUS20060066864A1High densitySemiconductor/solid-state device testing/measurementScattering properties measurementsOptical measurementsProcess control monitoring

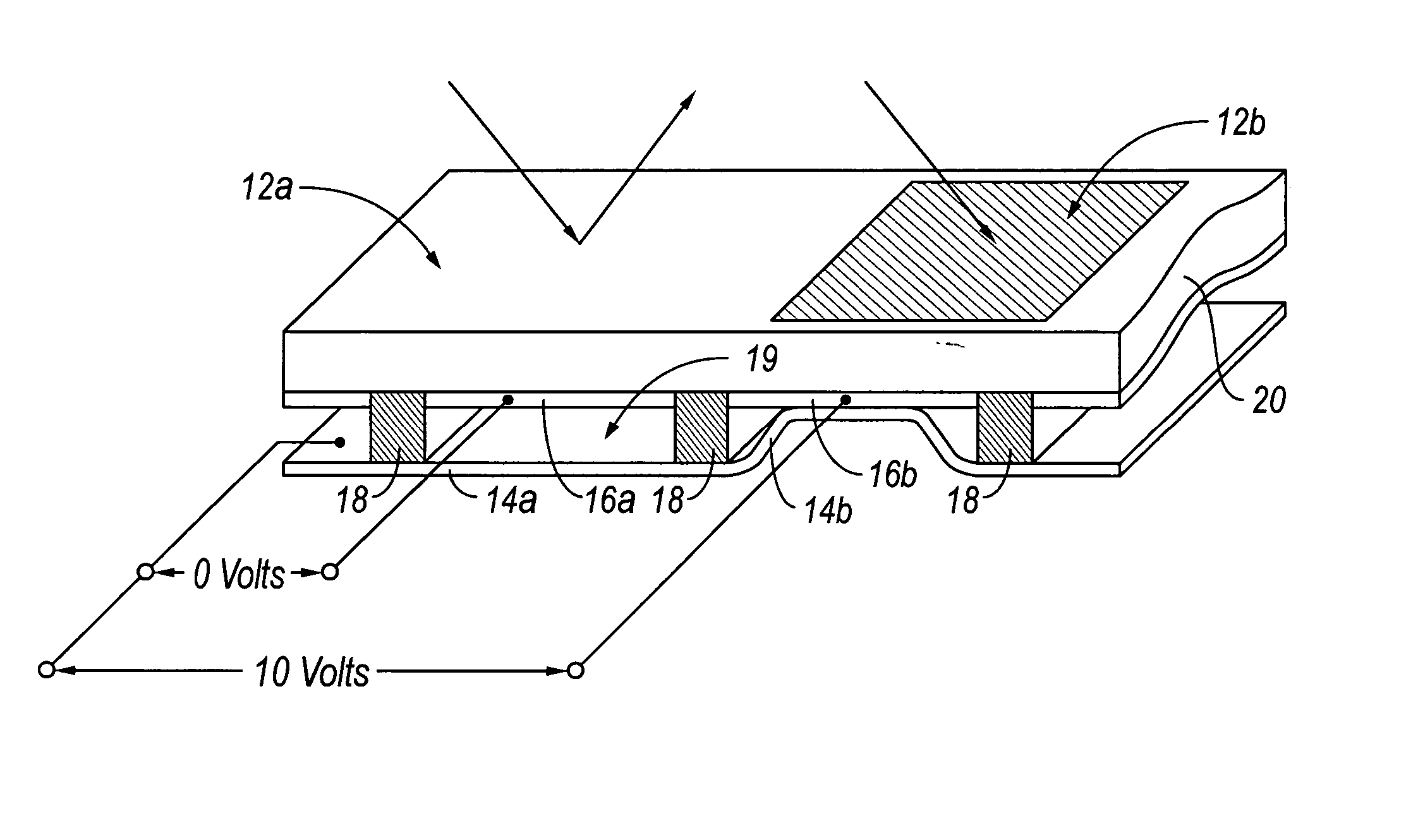

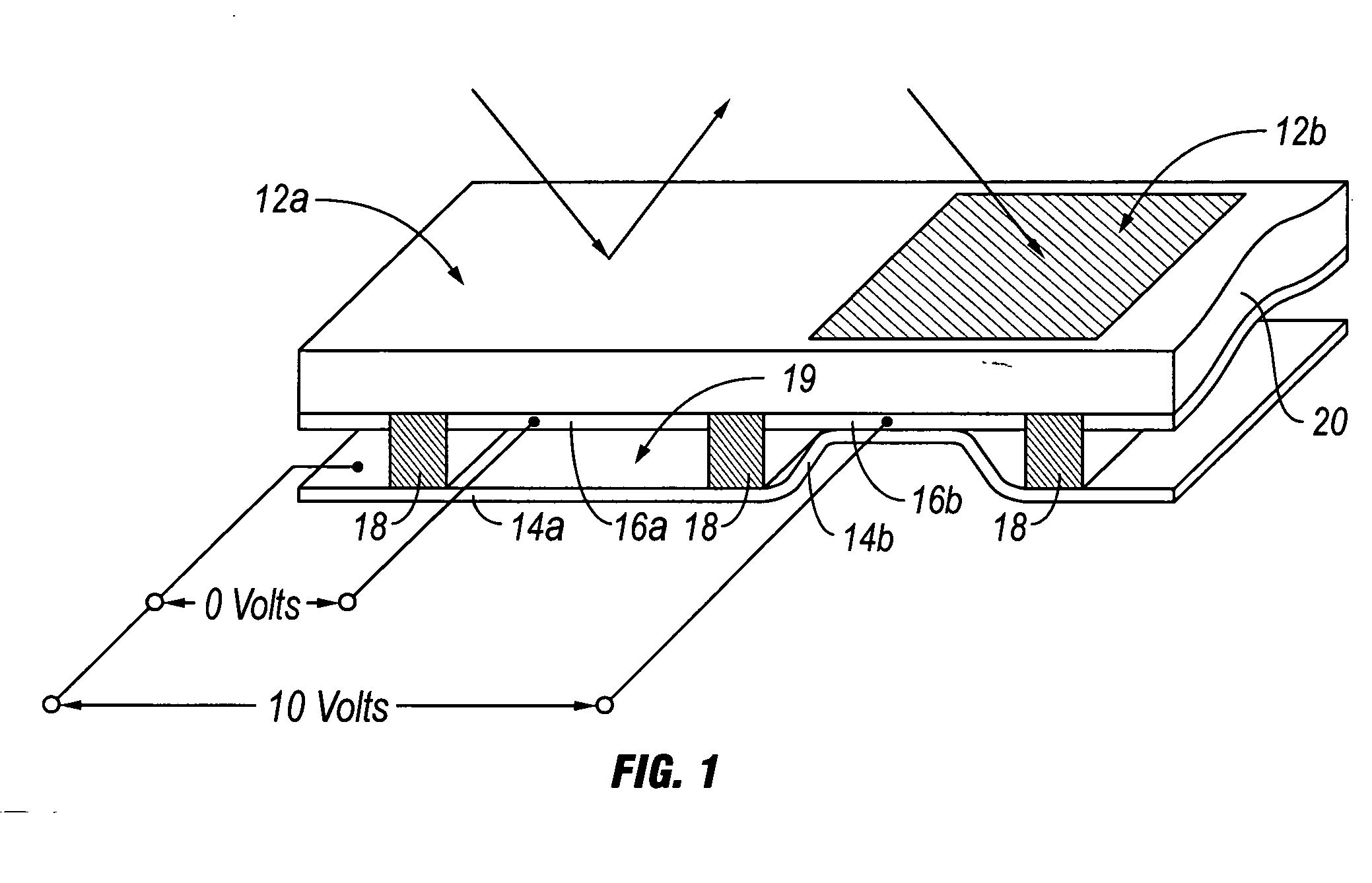

Process control monitors are disclosed that are produced using at least some of the same process steps used to manufacture a MEMS device. Analysis of the process control monitors can provide information regarding properties of the MEMS device and components or sub-components in the device. This information can be used to identify errors in processing or to optimize the MEMS device. In some embodiments, analysis of the process control monitors may utilize optical measurements.

Owner:SNAPTRACK

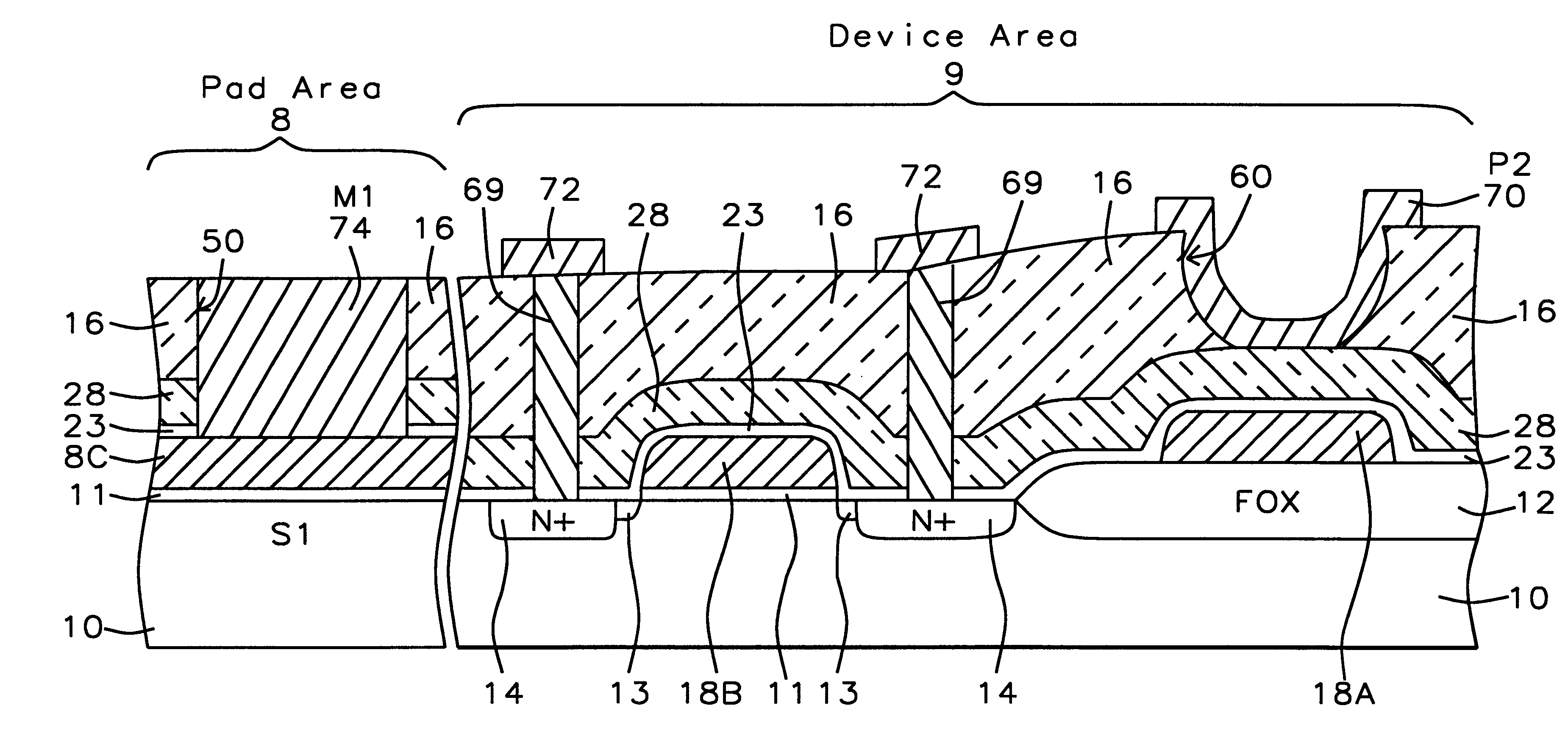

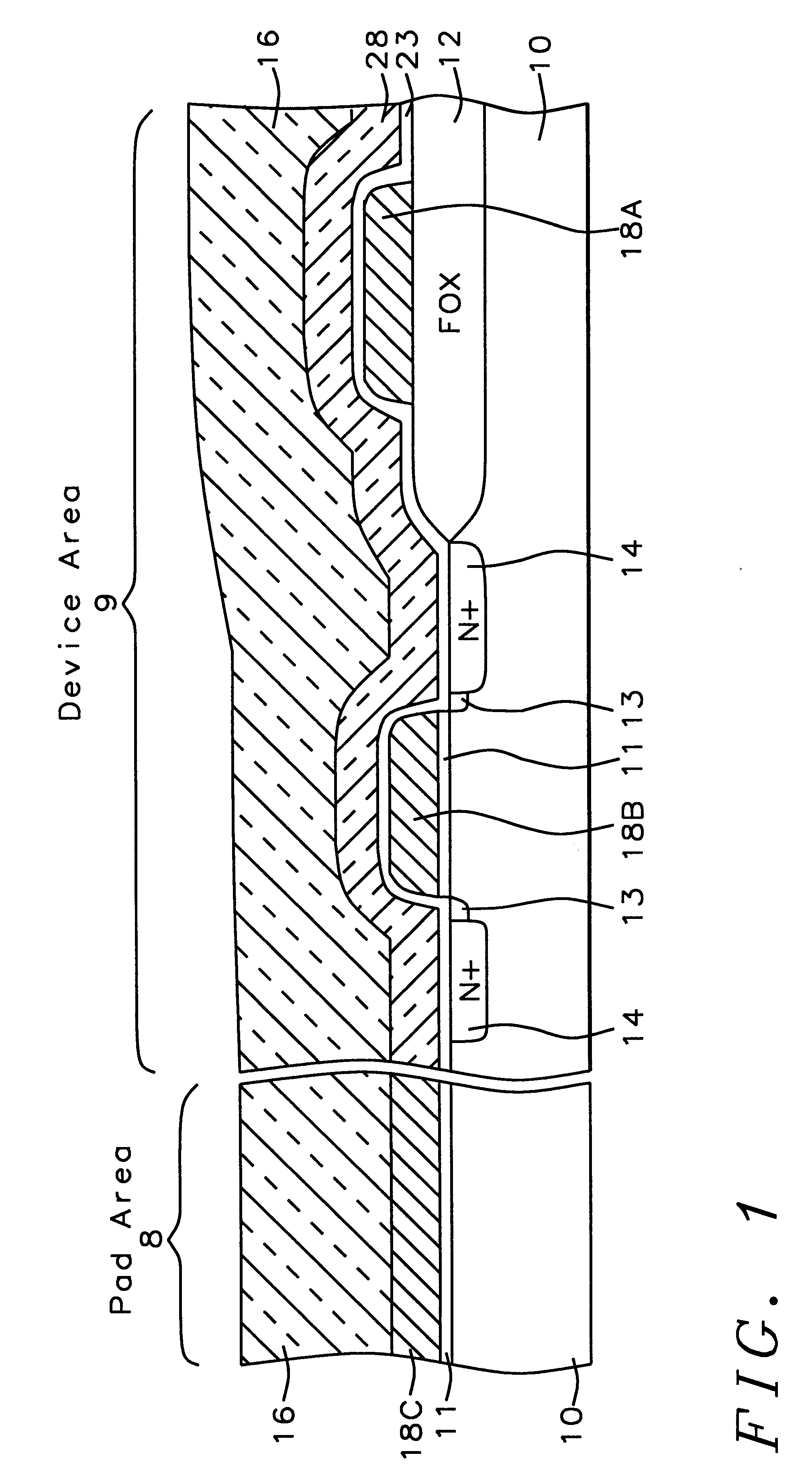

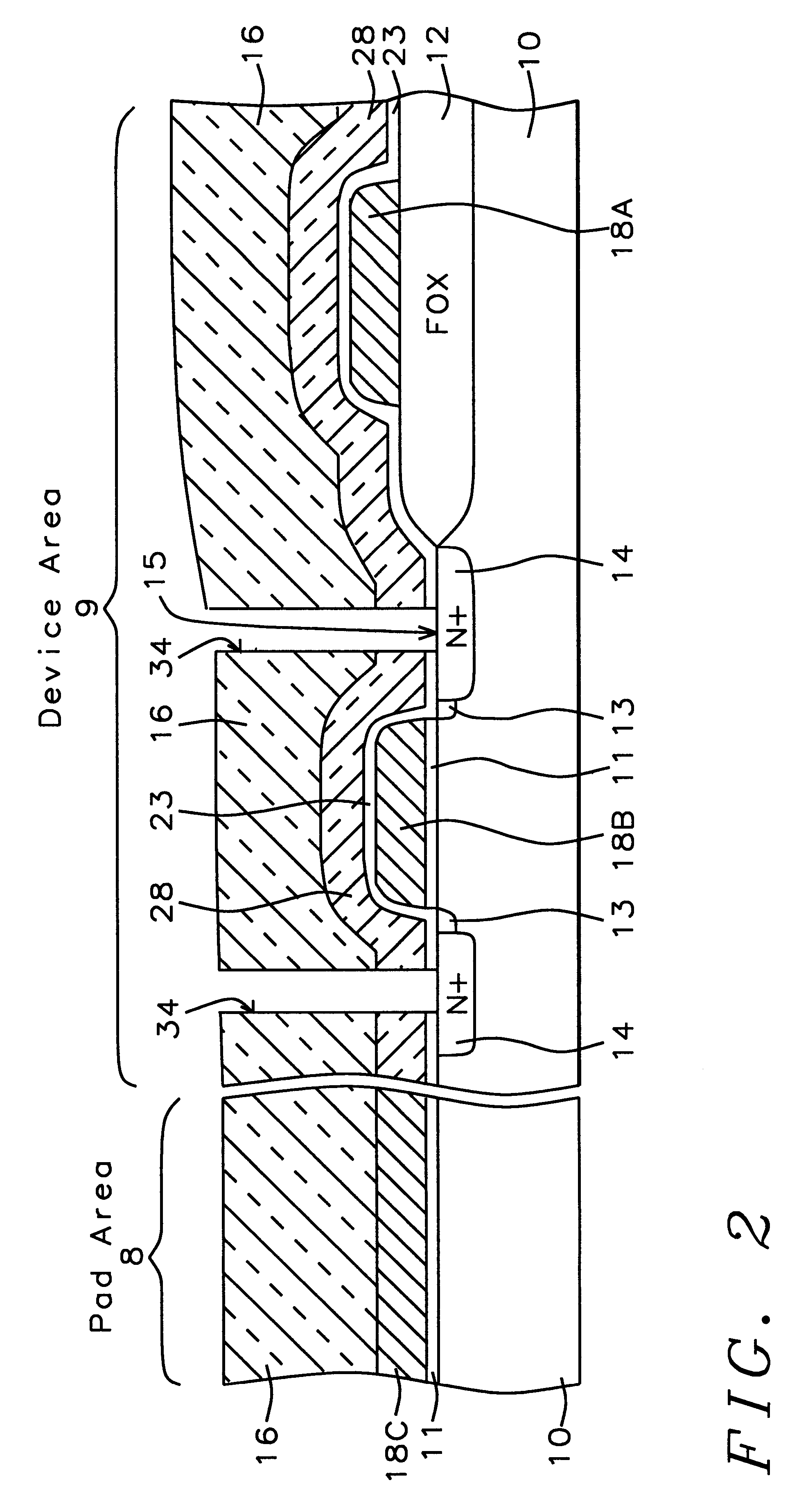

Method to increase the clear ratio of capacitor silicon nitride to improve the threshold voltage uniformity

InactiveUS6251724B1Improve uniformityTransistorSolid-state devicesEngineeringProcess control monitoring

A method to remove the silicon nitride capacitor dielectric layer from over the poly-1 layer on portions of the wafer including non-capacitor areas such as the pad contact area, process control monitor (PCM) testsite areas and scribe line areas. By removing the silicon nitride, H2 can penetrate to the polysilicon and thereby increase the uniformity of the VT. In a first embodiment of the invention, the silicon nitride capacitor dielectric layer is etched away from over the poly-1 layer in the pad area. The removal of the SiN layer allows H2 to penetrate into the poly-1 layer and improve the threshold voltage (VT). Uniformity of long channel VT-N was improved when we modify the pad struture of PCM to increase the clear out ratio of capacitor Si3N4 to 1.0584%. In a second embodiment of the invention, the silicon nitride capacitor dielectric is etched away from over the poly-1 layer in the process control monitor (PCM) testsite area between the chips. In a third embodiment of the invention, the silicon nitride capacitor dielectric is etched away from over the poly-1 layer in the scribe area between the between the chips.

Owner:TAIWAN SEMICON MFG CO LTD

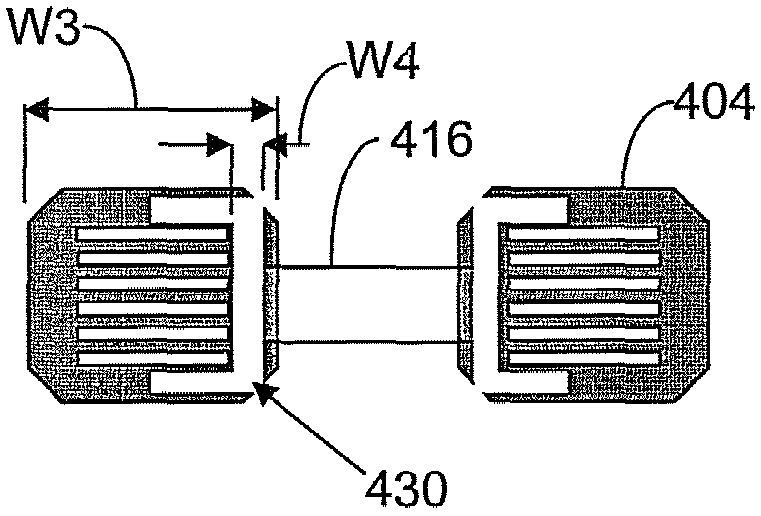

Pad structure and method of testing

ActiveUS20070290371A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDevice under testProcess control monitoring

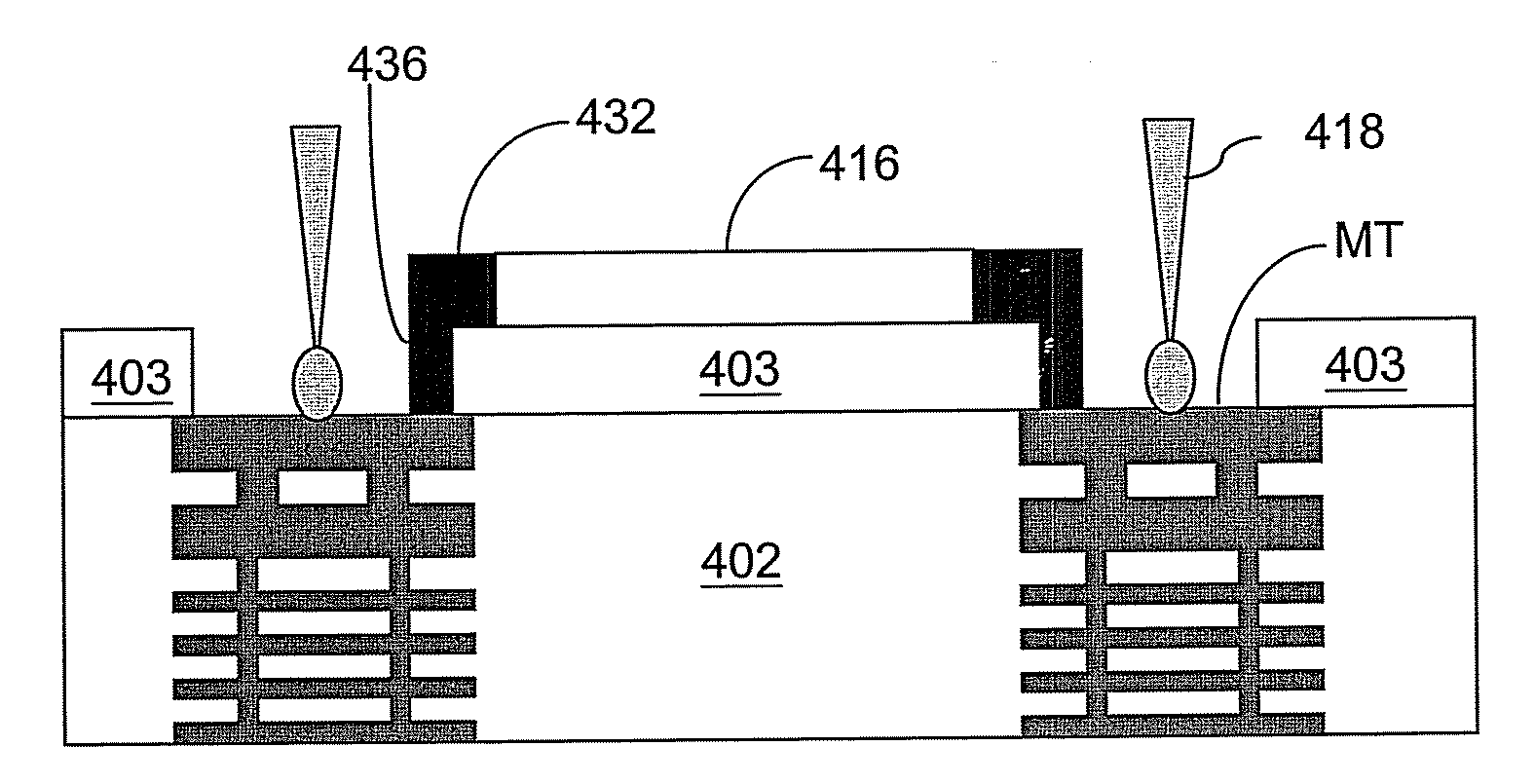

An interconnect structure includes: a plurality of dielectric layers having aligned process control monitor (PCM) pads, and a conductive structure above a topmost one of the PCM pads. The conductive structure electrically connects the topmost PCM pad to a device under test above a level of the topmost PCM pad. The conductive structure is sized and shaped so as to leave a majority portion of the topmost PCM pad exposed for access by a test probe.

Owner:TAIWAN SEMICON MFG CO LTD

Process control monitors for interferometric modulators

InactiveUS20060066872A1Scattering properties measurementsPhotomechanical apparatusEngineeringOptical measurements

Process control monitors are disclosed that are produced using at least some of the same process steps used to manufacture a MEMS device. Analysis of the process control monitors can provide information regarding properties of the MEMS device and components or sub-components in the device. This information can be used to identify errors in processing or to optimize the MEMS device. In some embodiments, analysis of the process control monitors may utilize optical measurements.

Owner:SNAPTRACK

Graphical process variable trend monitoring with zoom features for use in a process control system

ActiveCN105190459ANavigation Predictive and EffectiveProgramme controlError detection/correctionGraphicsDrill down

A process control monitoring system for a process control plant uses graphic trend symbols to assist in detecting and monitoring trends of process variables within the process control plant. A graphic display application within the process control monitoring system may implement and display each graphic trend symbol to graphically indicate or encapsulate current trend and value information of a process variable within the process control plant. The graphic display application may display the graphic trend symbol in a spatially realistic location within a graphical representation of the process control plant while maintaining the hierarchical structure or each hierarchical level of the process plant. The graphic display application may also include a zoom feature that enables a user to quickly drill down through tend data to obtain more information and to support problem identification and diagnosis tasks.

Owner:FISHER-ROSEMOUNT SYST INC

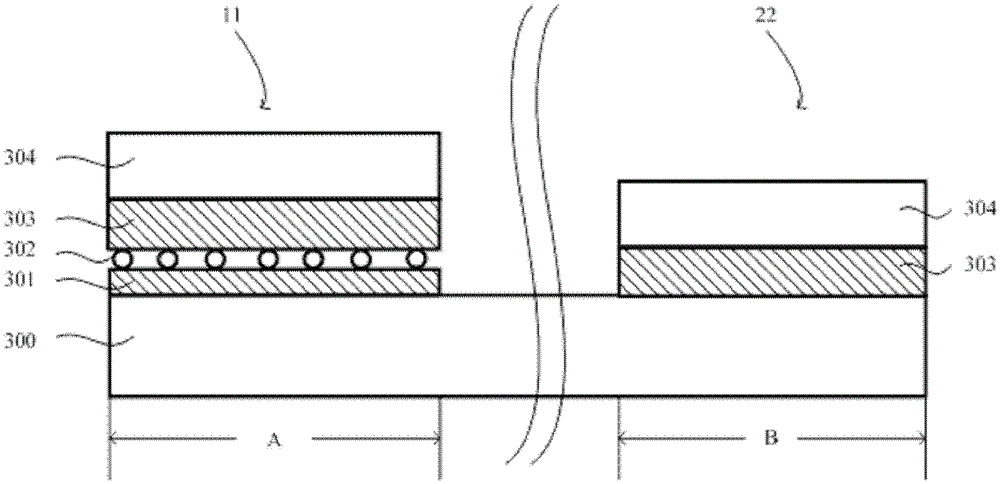

Method and device of MEMS process control monitoring and packaged MEMS with different cavity pressures

ActiveUS9249012B2Small sizeIncreased complexityDecorative surface effectsSemiconductor/solid-state device manufacturingOutgassingEngineering

A method for fabricating an integrated MEMS device and the resulting structure therefore. A control process monitor comprising a MEMS membrane cover can be provided within an integrated CMOS-MEMS package to monitor package leaking or outgassing. The MEMS membrane cover can separate an upper cavity region subject to leaking from a lower cavity subject to outgassing. Differential changes in pressure between these cavities can be detecting by monitoring the deflection of the membrane cover via a plurality of displacement sensors. An integrated MEMS device can be fabricated with a first and second MEMS device configured with a first and second MEMS cavity, respectively. The separate cavities can be formed via etching a capping structure to configure each cavity with a separate cavity volume. By utilizing an outgassing characteristic of a CMOS layer within the integrated MEMS device, the first and second MEMS cavities can be configured with different cavity pressures.

Owner:MCUBE INC +1

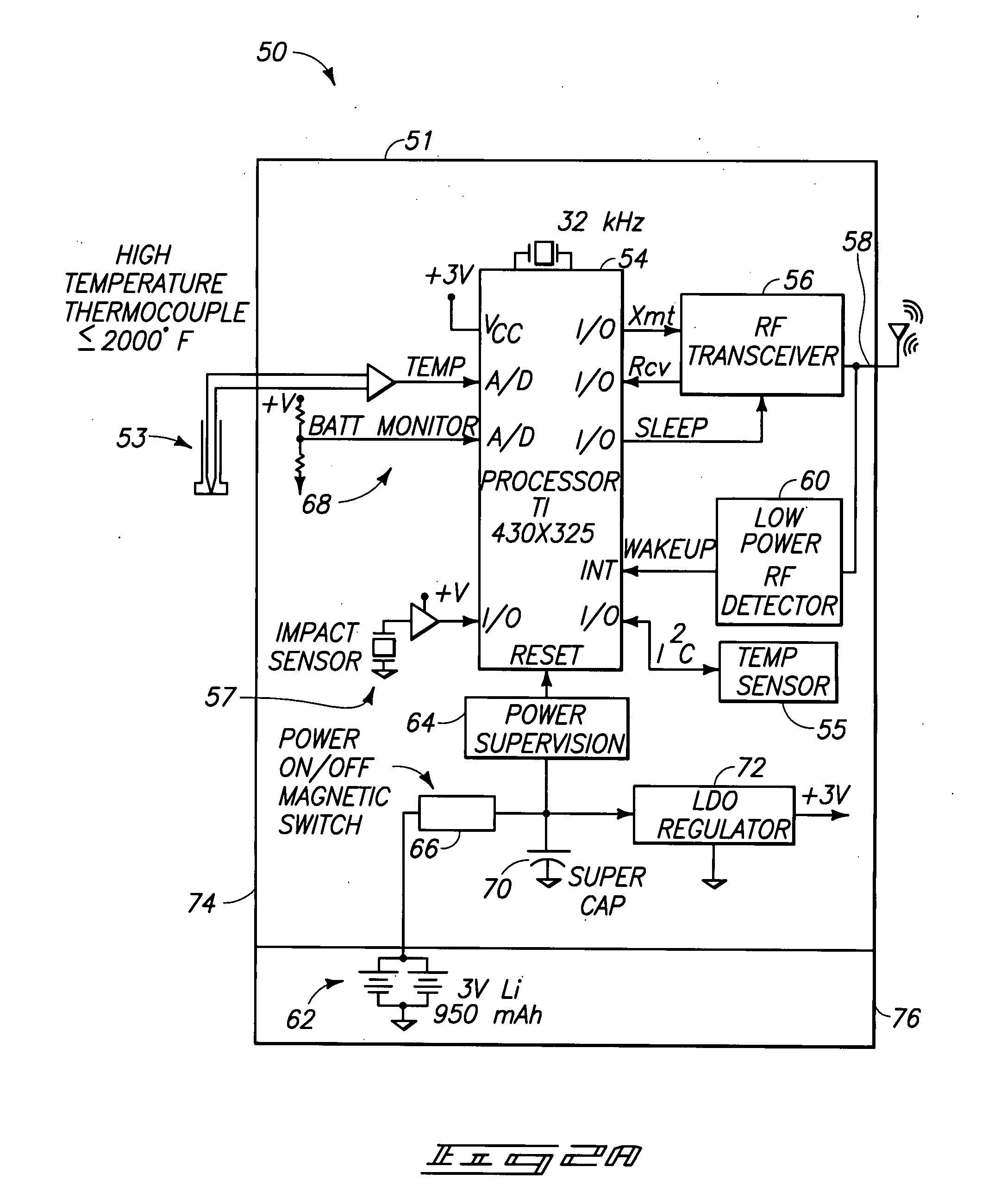

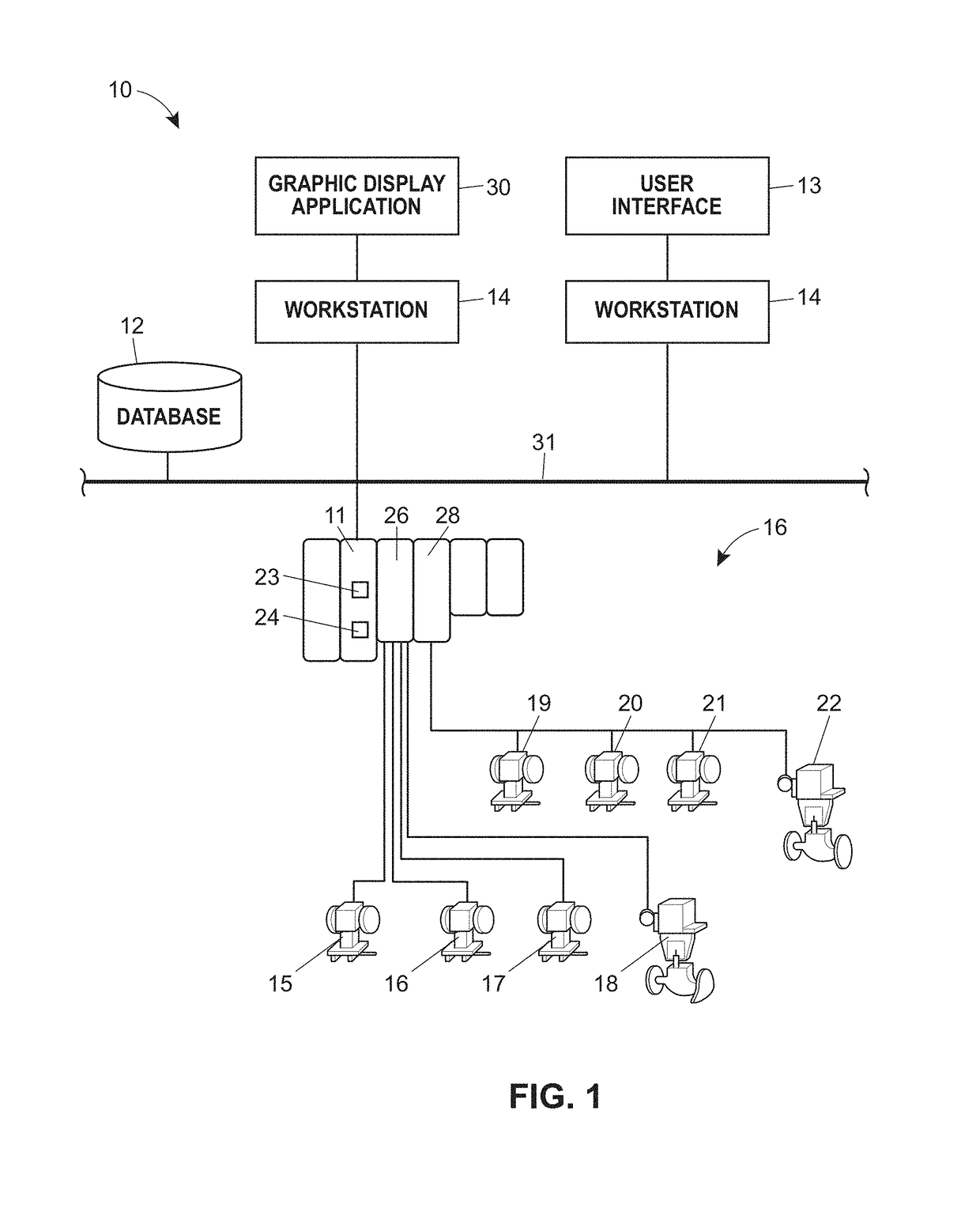

Process control monitoring systems, industrial plants, and process control monitoring methods

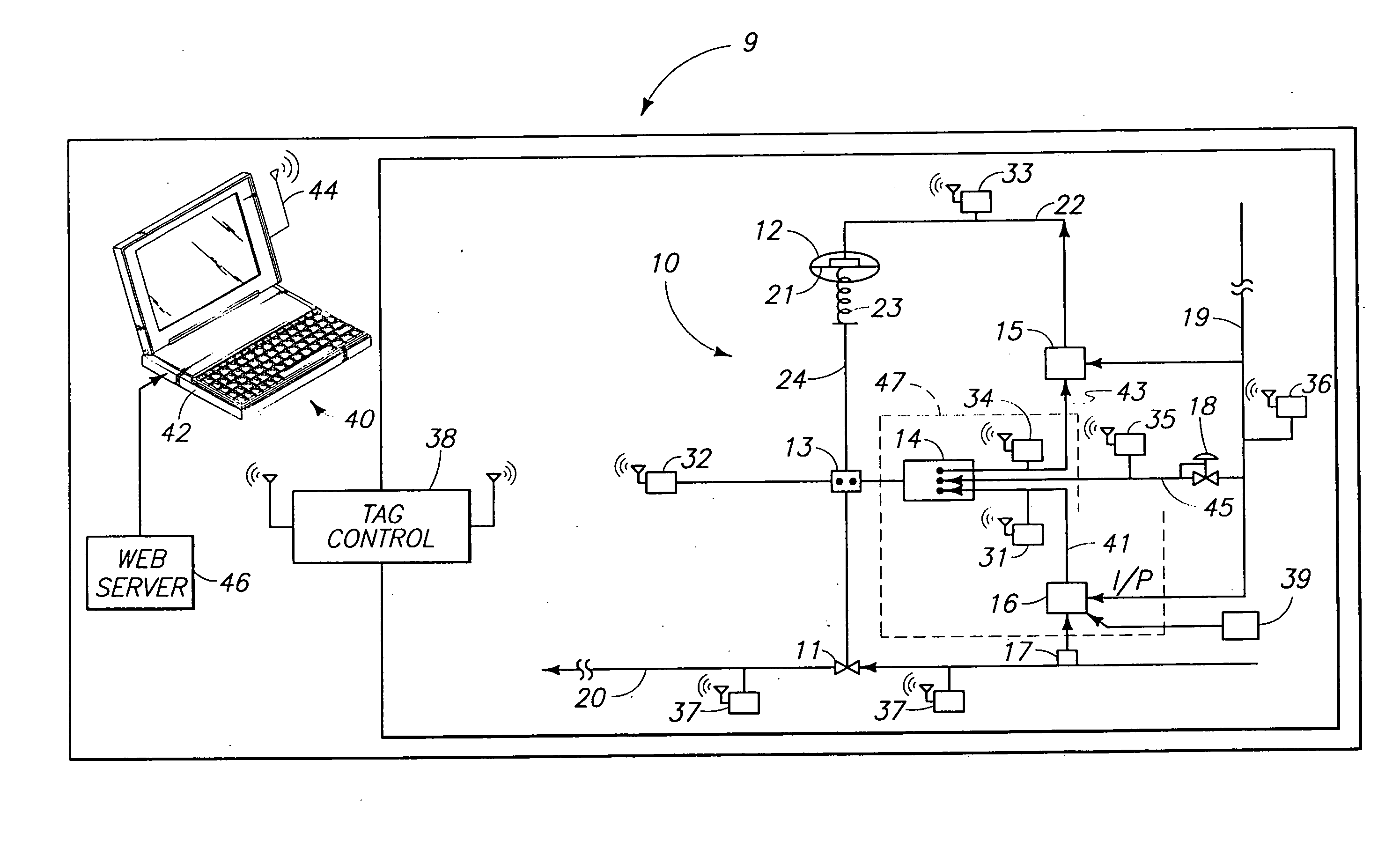

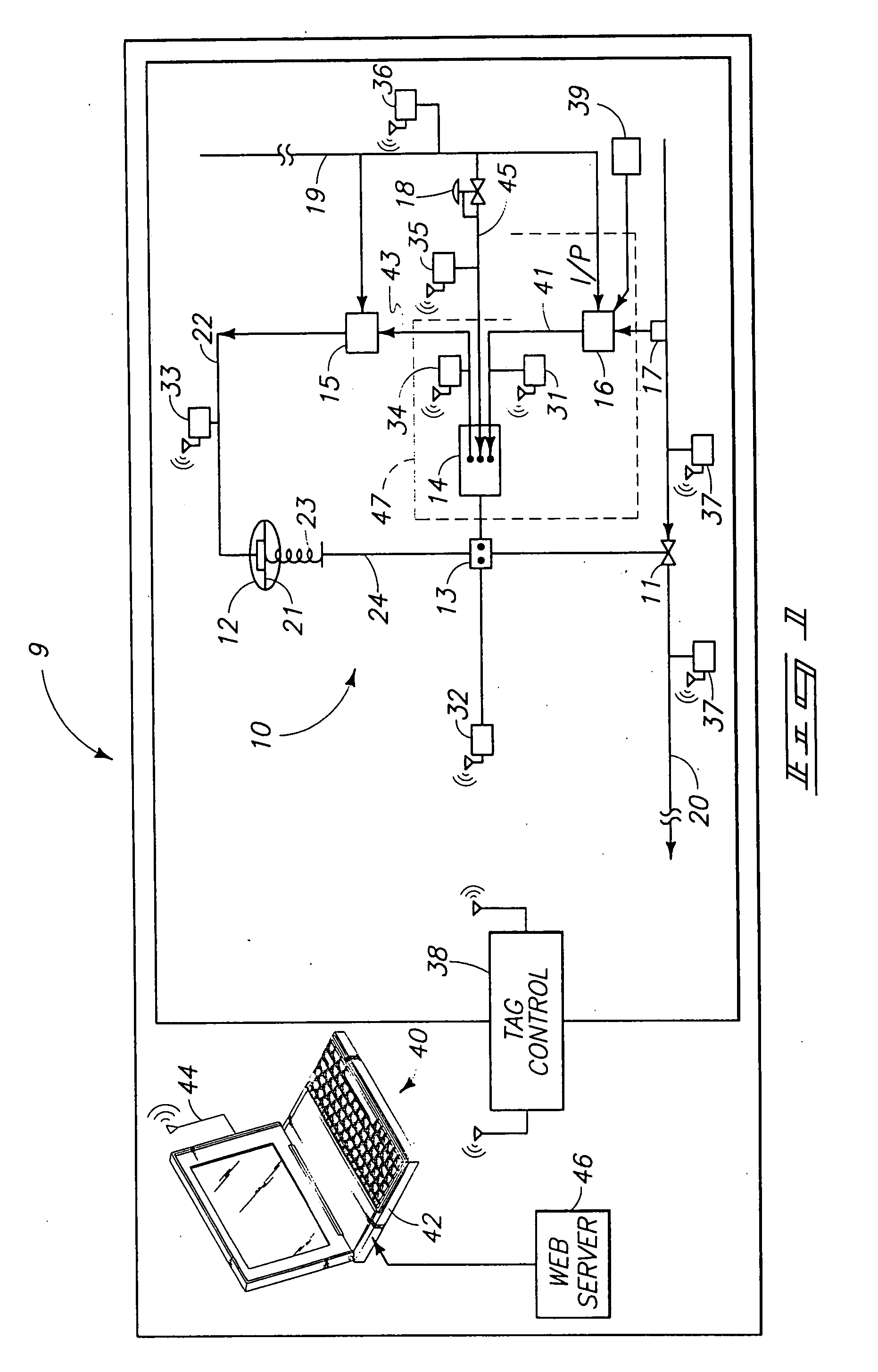

InactiveUS20070239400A1Valve arrangementsError detection/correctionEngineeringProcess control monitoring

A system comprises a valve; a plurality of RFID sensor assemblies coupled to the valve to monitor a plurality of parameters associated with the valve; a control tag configured to wirelessly communicate with the respective tags that are coupled to the valve, the control tag being further configured to communicate with an RF reader; and an RF reader configured to selectively communicate with the control tag, the reader including an RF receiver. Other systems and methods are also provided.

Owner:BATTELLE MEMORIAL INST

Process control monitors for interferometric modulators

InactiveUS20060066871A1High densityScattering properties measurementsUsing optical meansOptical measurementsProcess control monitoring

Process control monitors are disclosed that are produced using at least some of the same process steps used to manufacture a MEMS device. Analysis of the process control monitors can provide information regarding properties of the MEMS device and components or sub-components in the device. This information can be used to identify errors in processing or to optimize the MEMS device. In some embodiments, analysis of the process control monitors may utilize optical measurements.

Owner:SNAPTRACK

Graphical process variable trend monitoring, predictive analytics and fault detection in process control system

ActiveCN106843168ANavigation worksTesting/monitoring control systemsProgramme total factory controlProblem identificationIn process control

A process control monitoring system for a process control plant uses graphic trend symbols to assist in detecting and monitoring trends of process variables within the process control plant. A graphic display application within the process control monitoring system may implement and display each graphic trend symbol to graphically indicate or encapsulate current trend and value information of a process variable within the process control plant. The graphic display application may display the graphic trend symbol in a spatially realistic location within a graphical representation of the process control plant while maintaining the hierarchical structure or each hierarchical level of the process plant. The graphic display application may also include a navigation pane and a zoom feature that enable a user to quickly drill down through tend data to obtain more information and to support problem identification and diagnosis tasks.

Owner:FISHER-ROSEMOUNT SYST INC

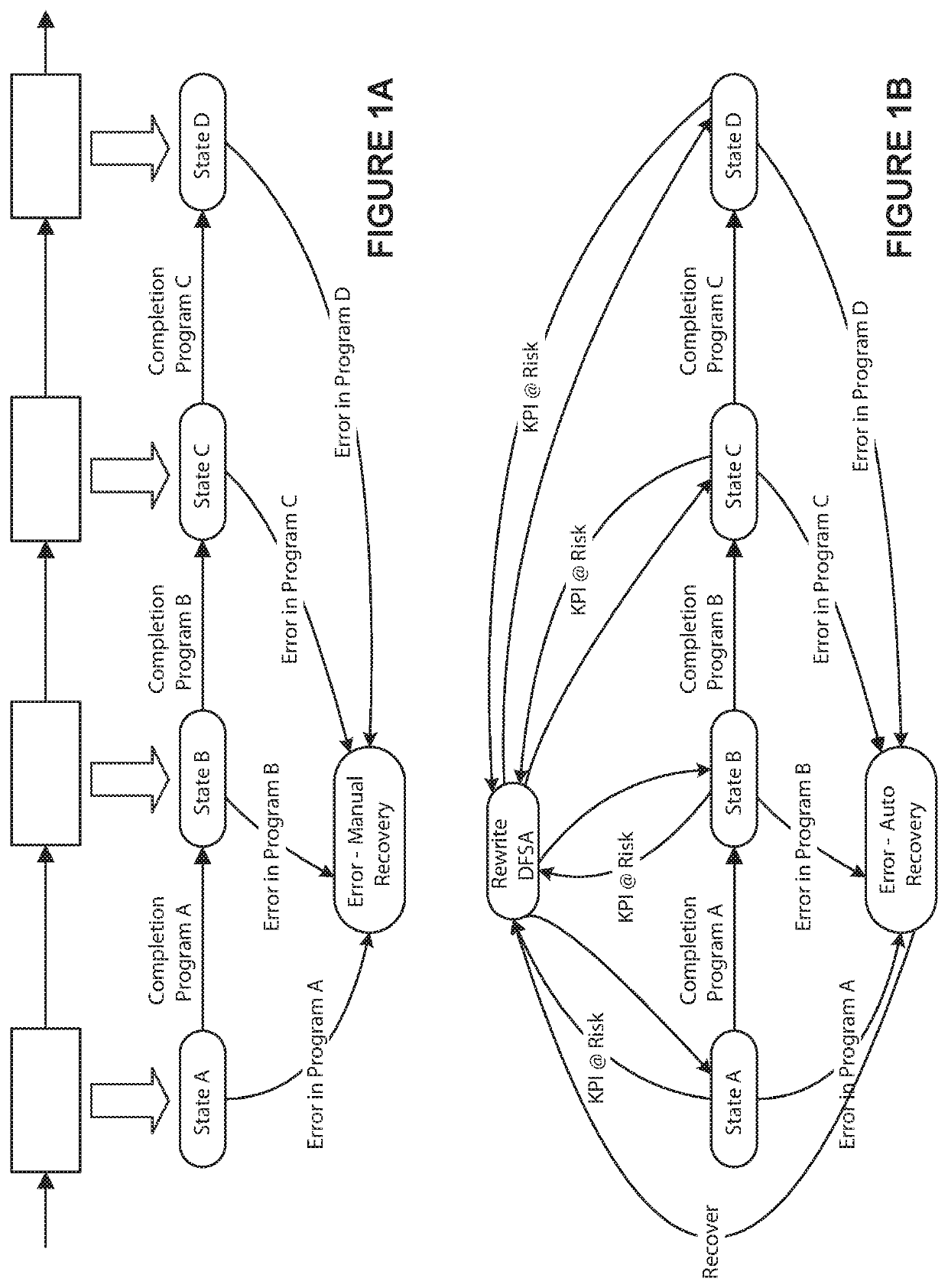

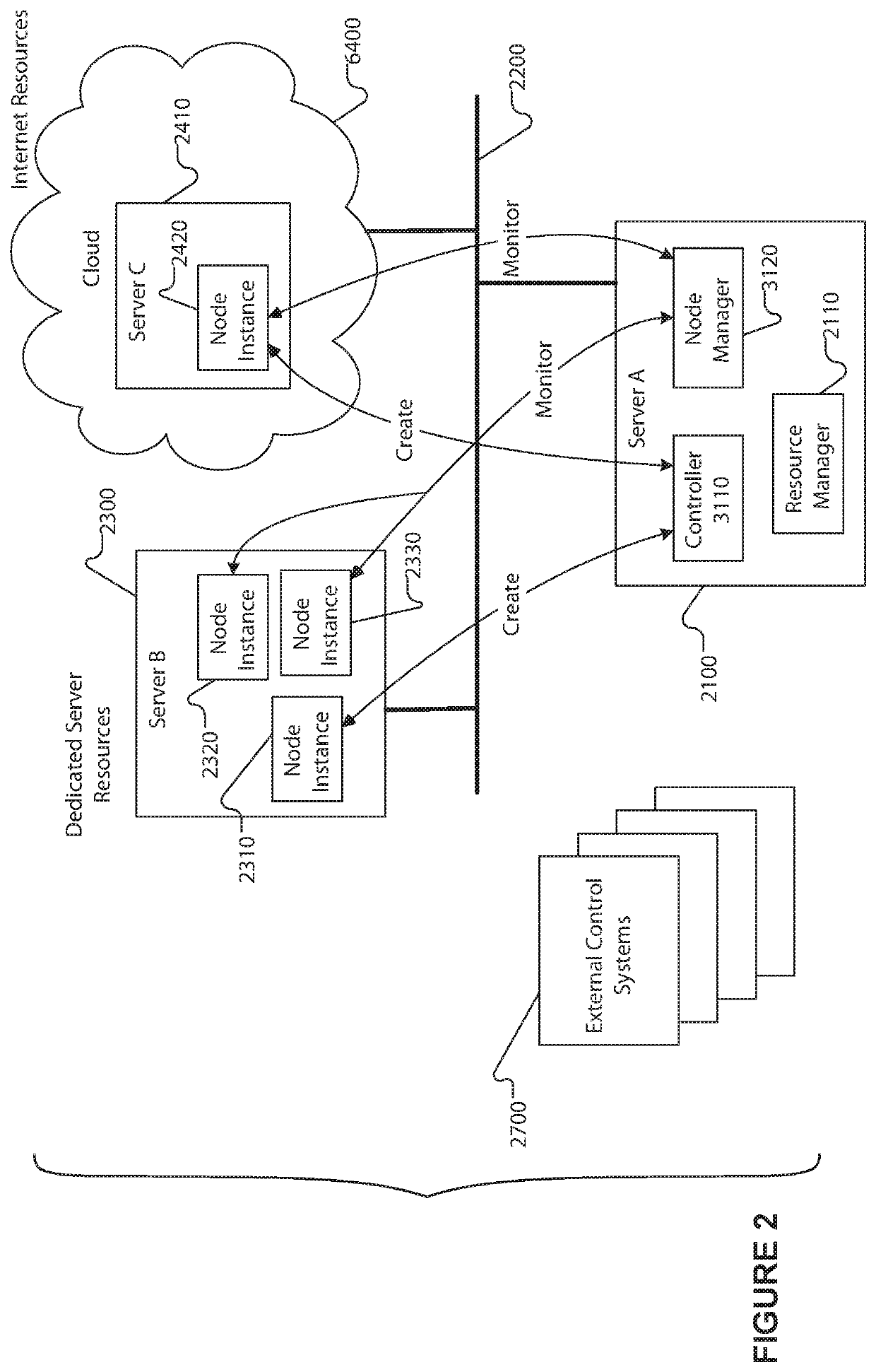

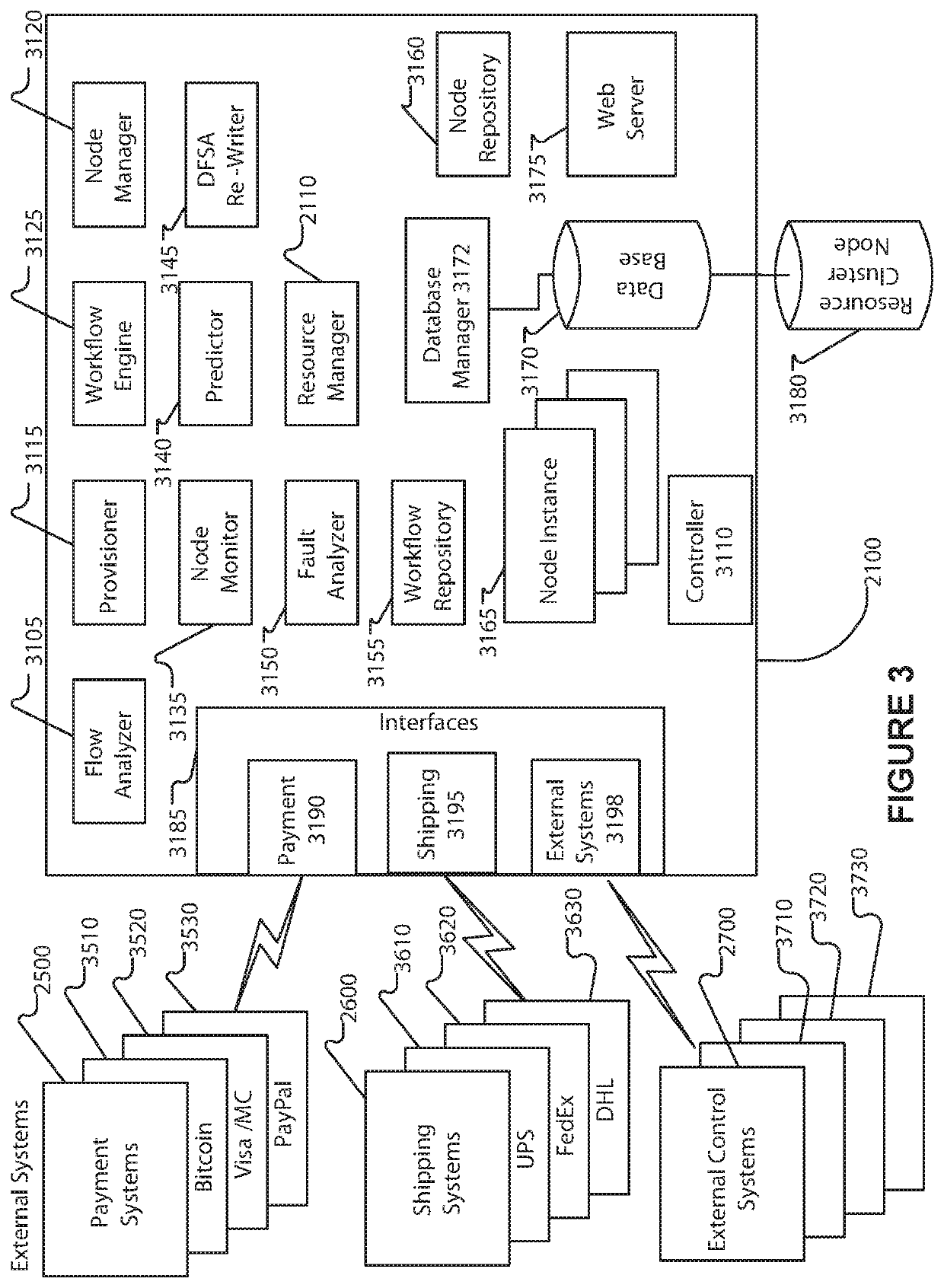

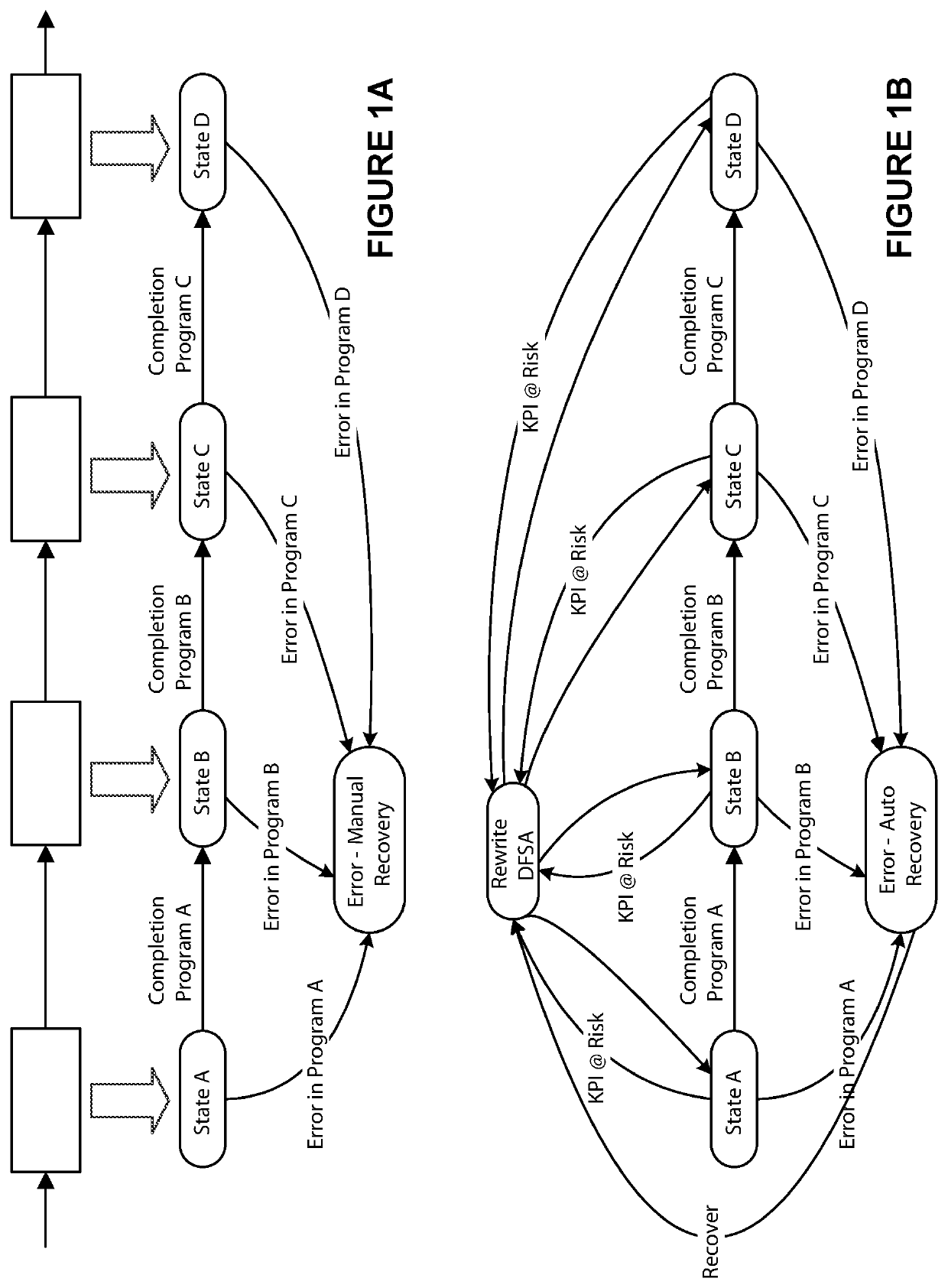

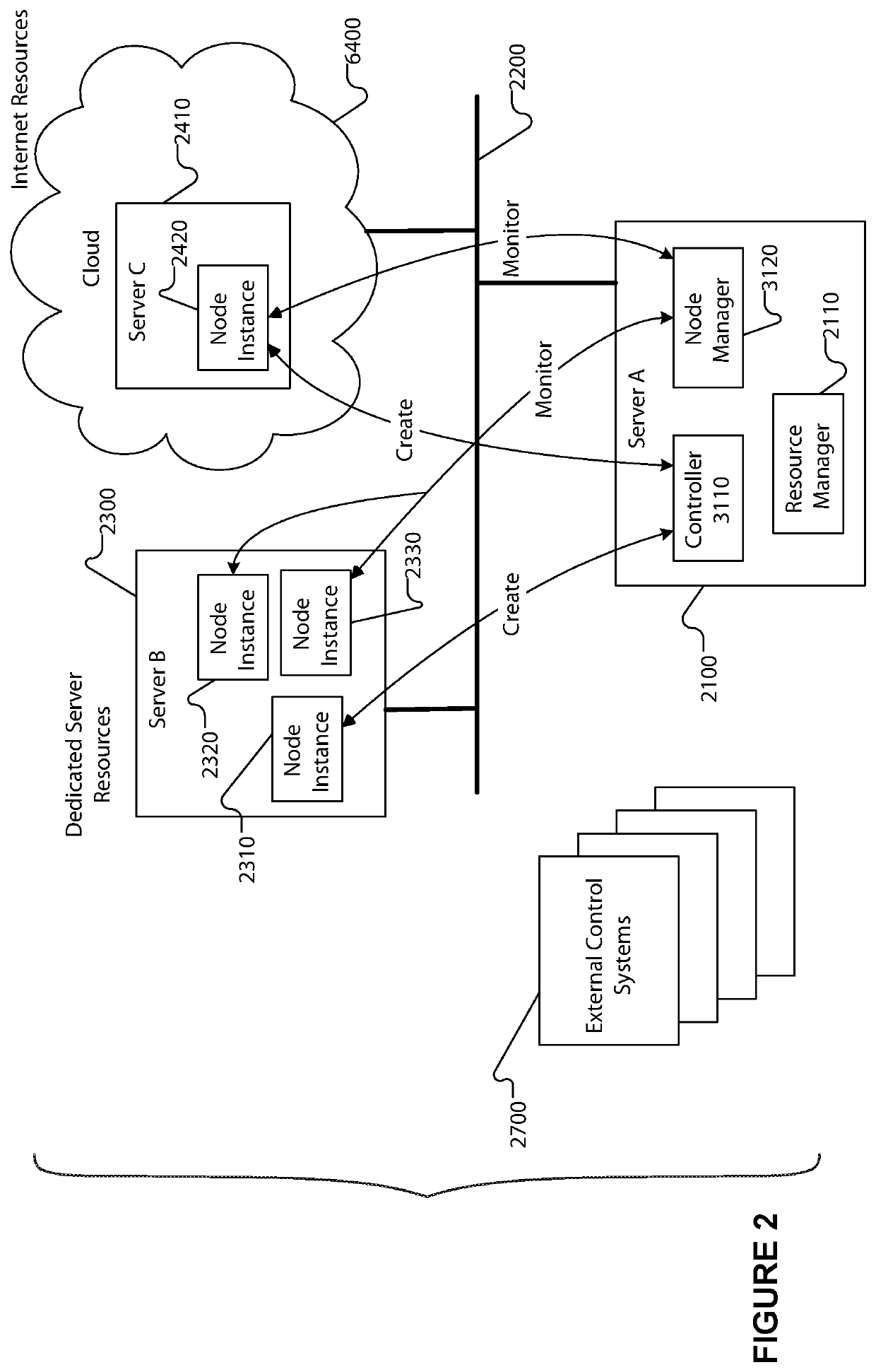

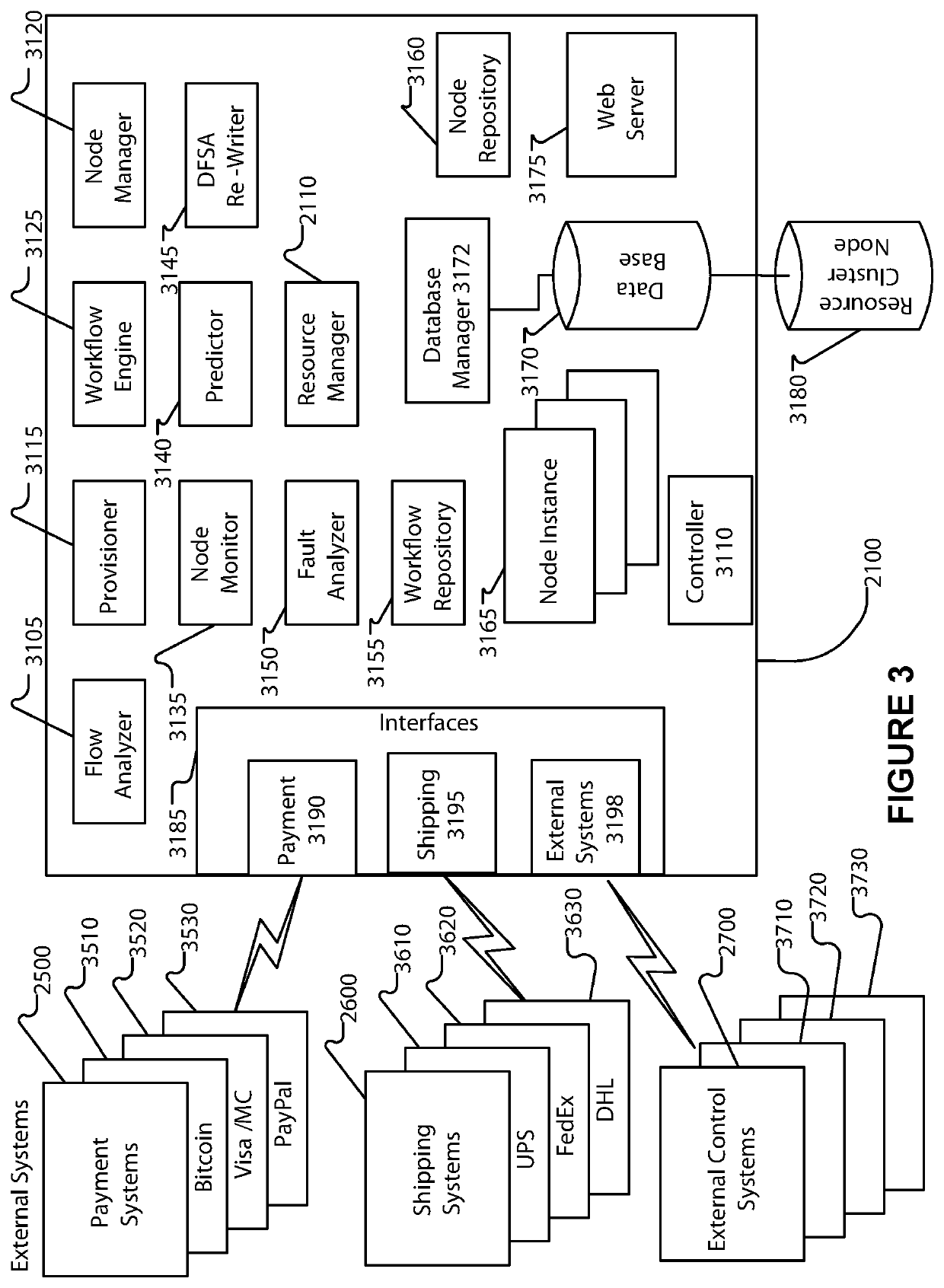

Dynamically reallocating state machines

ActiveUS10996658B1Expand the scope of operationImprove abilitiesTechnology managementResourcesControl systemProcess engineering

The systems and methods described provide improved process control operating range and capabilities and integrate process control monitoring and management with broader process automation (PA) systems process management, extending the real-time operation and control of a process control system to process handling of a PA system, and extending PA-style process management by adding real-time process controls and monitoring, and adding new functionality by permitting management of these processes to externally defined completion goals. This combination provides new functionality in dynamically determined process flexibility, extended operating range and extended process recipe definition capabilities for process control systems using this technology, and provides improved error recovery and exception handling of traditional PA systems.

Owner:SALESWARP +1

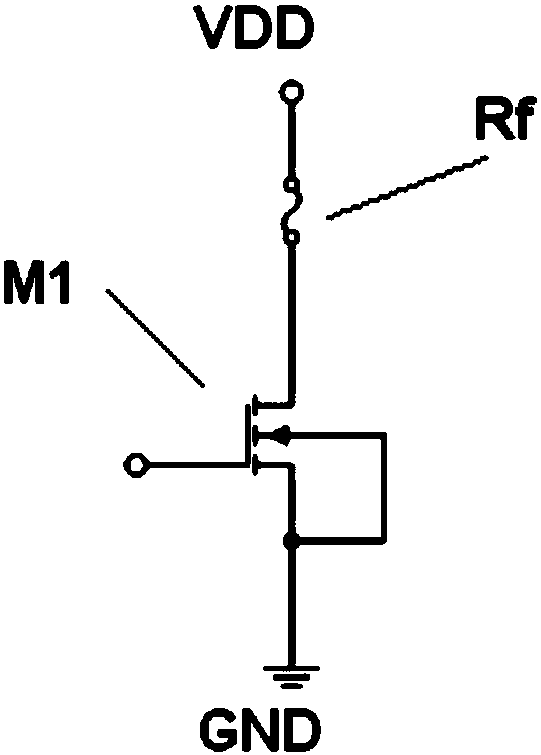

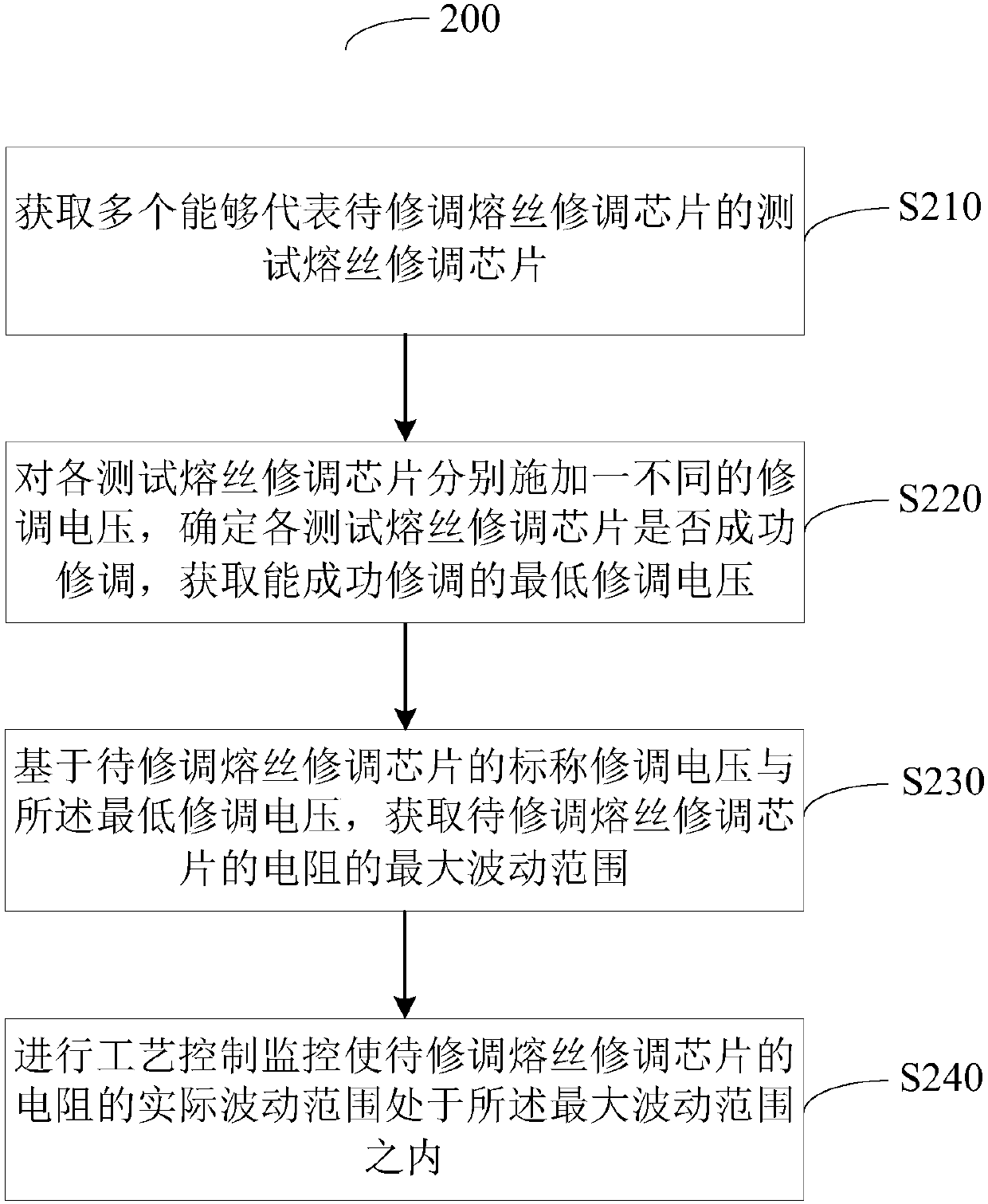

Method for manufacturing fuse trimming chip

ActiveCN107785306AImprove reliabilitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingProcess control monitoringProcess control

The invention provides a method for manufacturing a fuse trimming chip. The method comprises the steps of: acquiring a plurality of test fuse trimming chips capable of representing a fuse trimming chip to be trimmed; applying a different trimming voltage to each test fuse trimming chip, determining whether each test fuse trimming chip is successfully trimmed, and acquiring the lowest trimming voltage for successful trimming; based on the nominal trimming voltage of the fuse trimming chip to be trimmed and the lowest trimming voltage, acquiring the maximum fluctuation range of the resistance ofthe fuse trimming chip to be trimmed; and performing process control monitoring so that the actual fluctuation range of the resistance of the fuse trimming chip to be trimmed is within the maximum fluctuation range. The method can calculate the maximum fluctuation range allowed by the resistance of the fuse trimming chip to be trimmed with process fluctuation, so that the actual fluctuation rangeof the resistance of the fuse trimming chip to be trimmed can be within the maximum allowable fluctuation range through process control monitoring, and the fuse trimming reliability is improved.

Owner:CSMC TECH FAB2 CO LTD

Process control monitors for interferometric modulators

InactiveUS20060077381A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsOptical measurementsProcess control monitoring

Process control monitors are disclosed that are produced using at least some of the same process steps used to manufacture a MEMS device. Analysis of the process control monitors can provide information regarding properties of the MEMS device and components or sub-components in the device. This information can be used to identify errors in processing or to optimize the MEMS device. In some embodiments, analysis of the process control monitors may utilize optical measurements.

Owner:SNAPTRACK

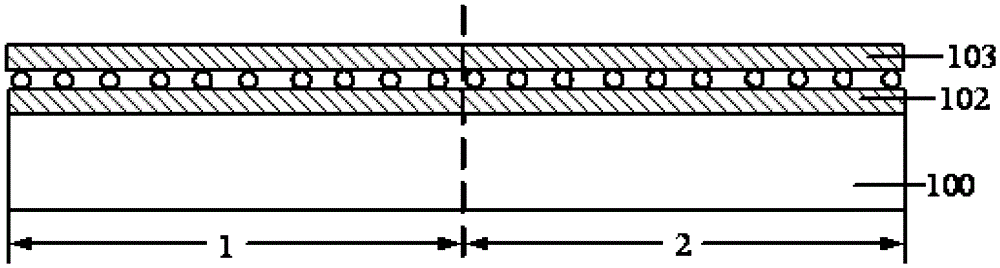

BCB thickness on-chip monitoring and control method and device

PendingCN111063627ASmall loss areaAvoid damageSemiconductor/solid-state device testing/measurementPolarisation-affecting propertiesWaferMonitoring and control

The invention discloses a BCB thickness on-chip monitoring and control method and device. The method comprises the following steps: preparing a monitoring graph on an epitaxial wafer; spin-coating thesurface of a substrate with BCB glue and heating the BCB glue for curing; testing the thickness of the BCB layer by adopting a micro-area reflection interference method; and etching the BCB layer byadopting a dry etching process, and repeatedly testing the BCB thickness of the monitoring area. According to the monitoring method, the BCB thicknesses of different areas on the wafer can be rapidlyobtained, and the surface of the wafer cannot be damaged. The method can be used for a BCB planarization process of an InP HBT device, on-chip real-time monitoring of the BCB thickness can be achieved, and the production efficiency is effectively improved. Process control monitoring is carried out by setting a specific monitoring graph, real-time monitoring of the BCB thicknesses of different areas is achieved, and the process control capacity is effectively improved.

Owner:CETC GUOJI SOUTHERN GRP CO LTD

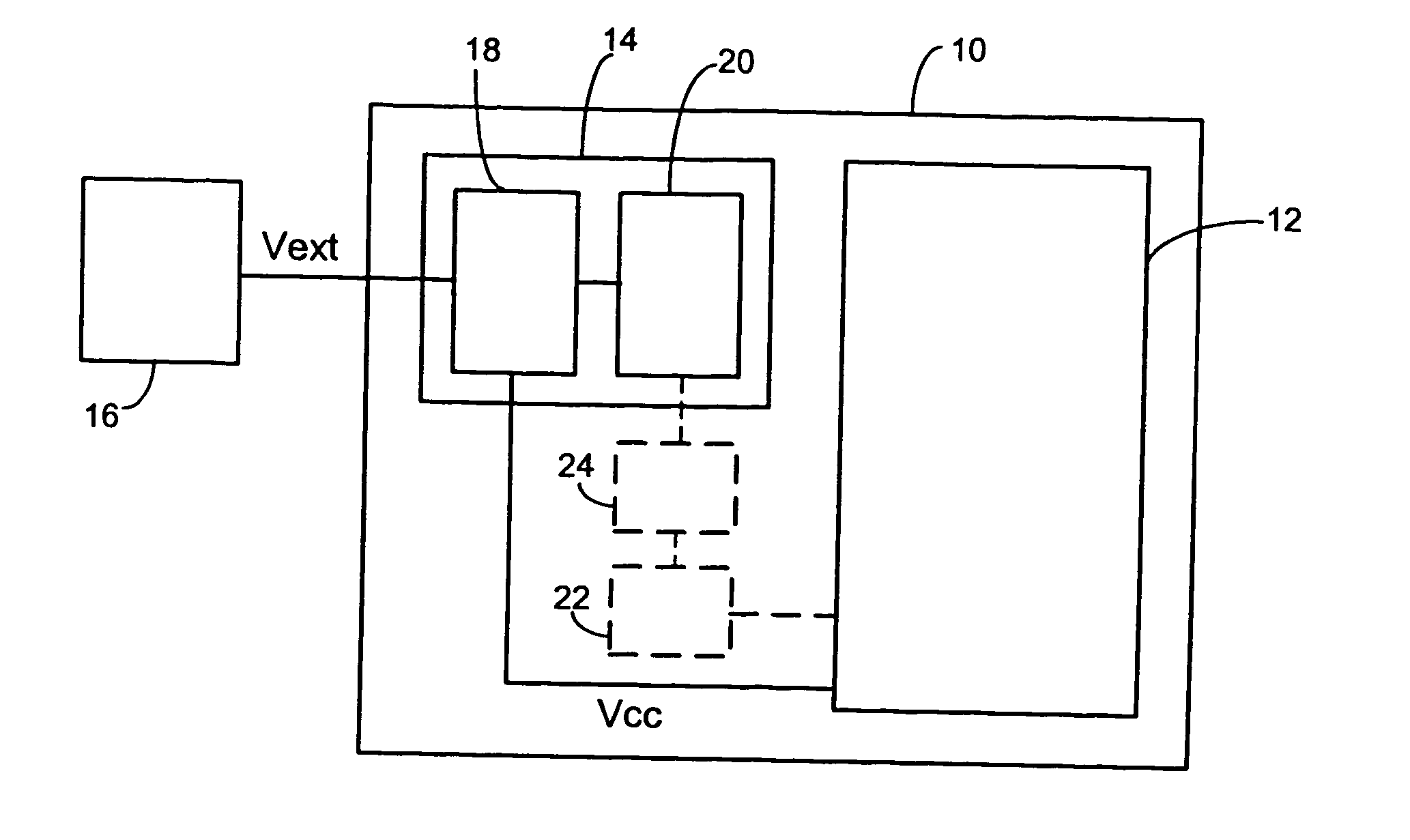

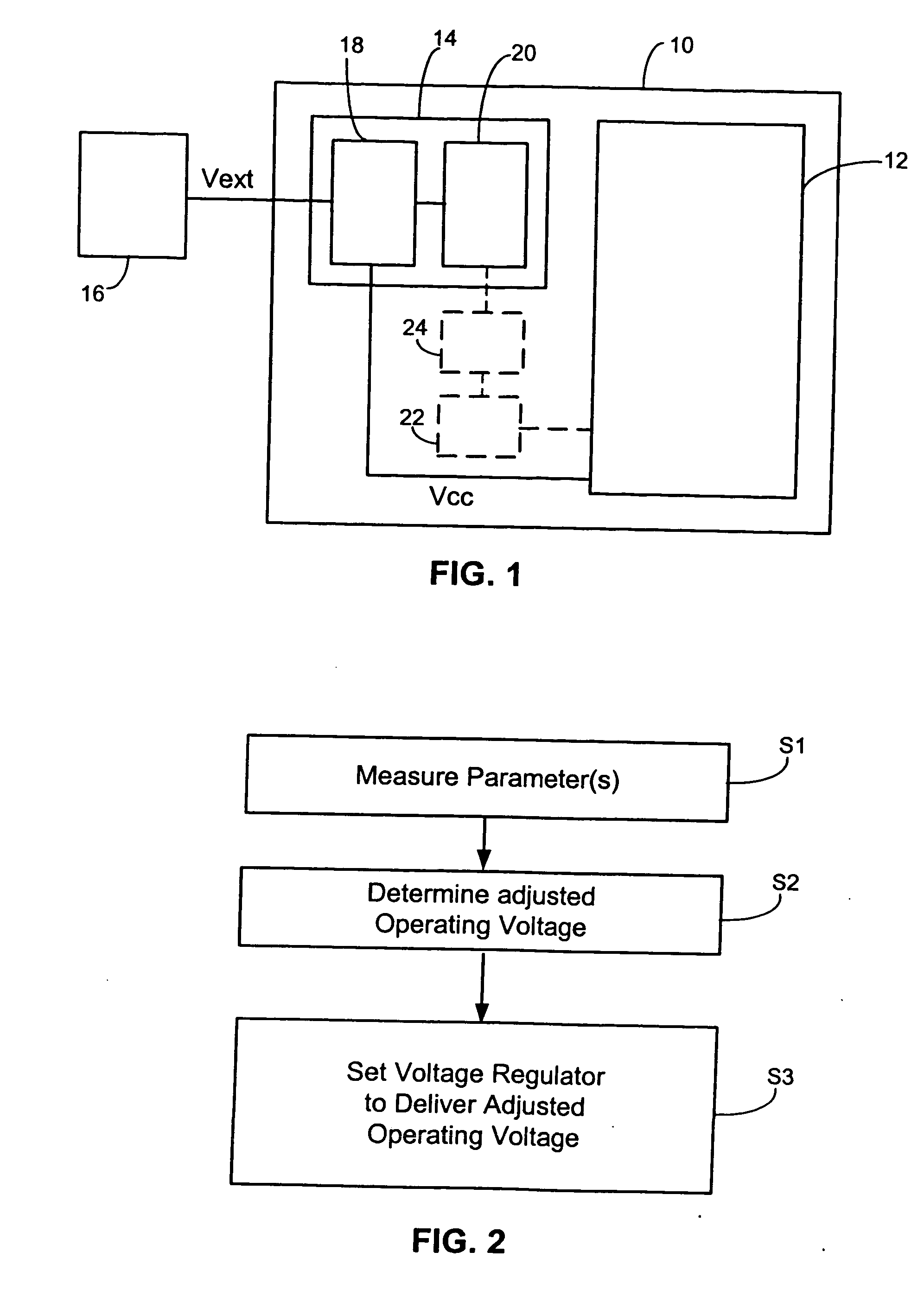

PAD structure and method of testing

ActiveUS7679195B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringProcess control monitoring

Owner:TAIWAN SEMICON MFG CO LTD

Graphical process variable trend monitoring for a process control system

ActiveUS10013149B2Assist in detectingEasy to distinguishElectric testing/monitoringInput/output processes for data processingProblem identificationApplication software

A process control monitoring system for a process control plant uses graphic trend symbols to assist in detecting and monitoring trends of process variables within the process control plant. A graphic display application within the process control monitoring system may implement and display each graphic trend symbol to graphically indicate or encapsulate current trend and value information of a process variable within the process control plant. The graphic display application may display the graphic trend symbol in a spatially realistic location within a graphical representation of the process control plant while maintaining the hierarchical structure or each hierarchical level of the process plant. The graphic display application may also include a zoom feature that enables a user to quickly drill down through tend data to obtain more information and to support problem identification and diagnosis tasks.

Owner:FISHER-ROSEMOUNT SYST INC

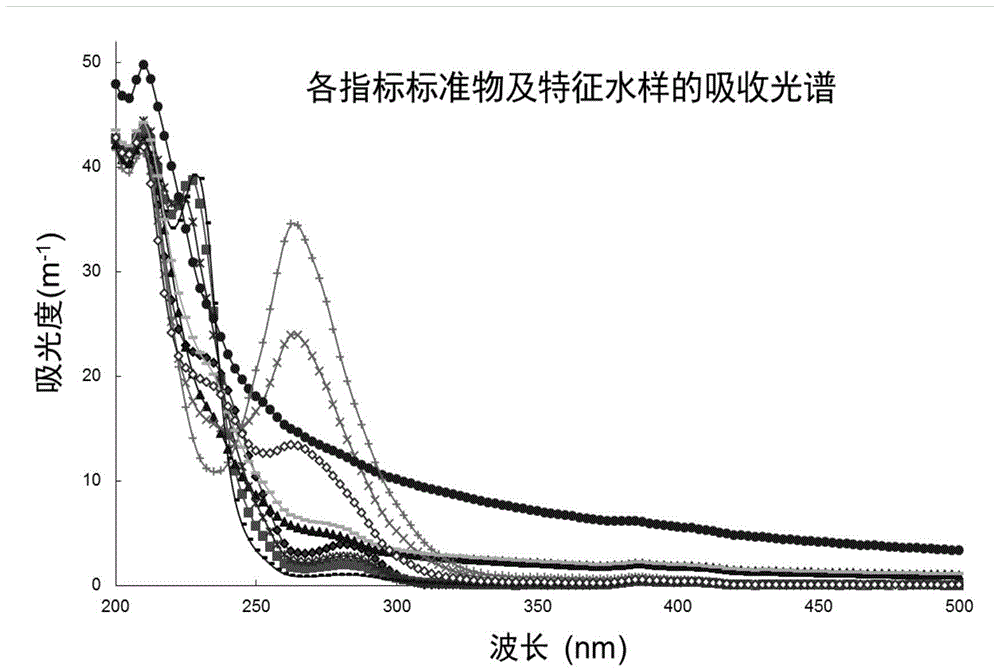

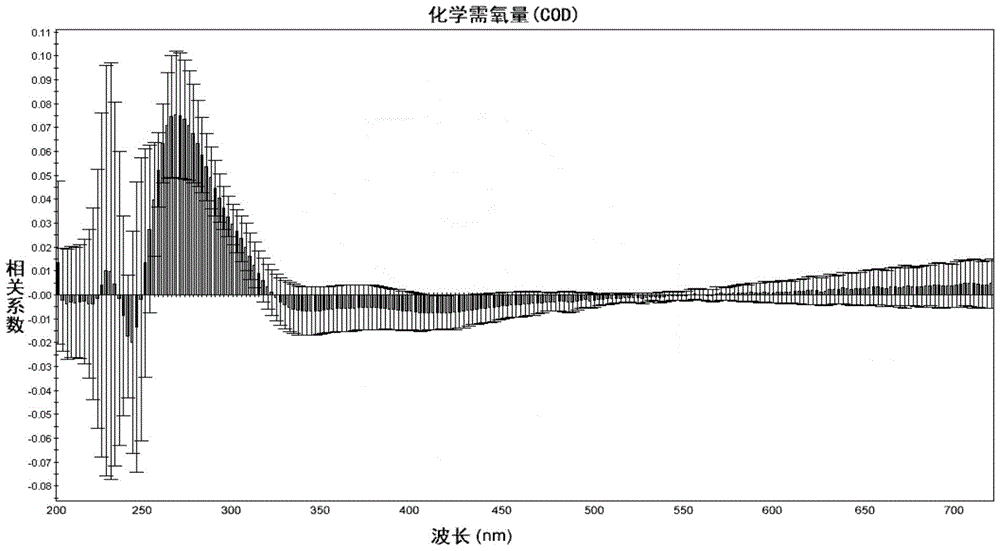

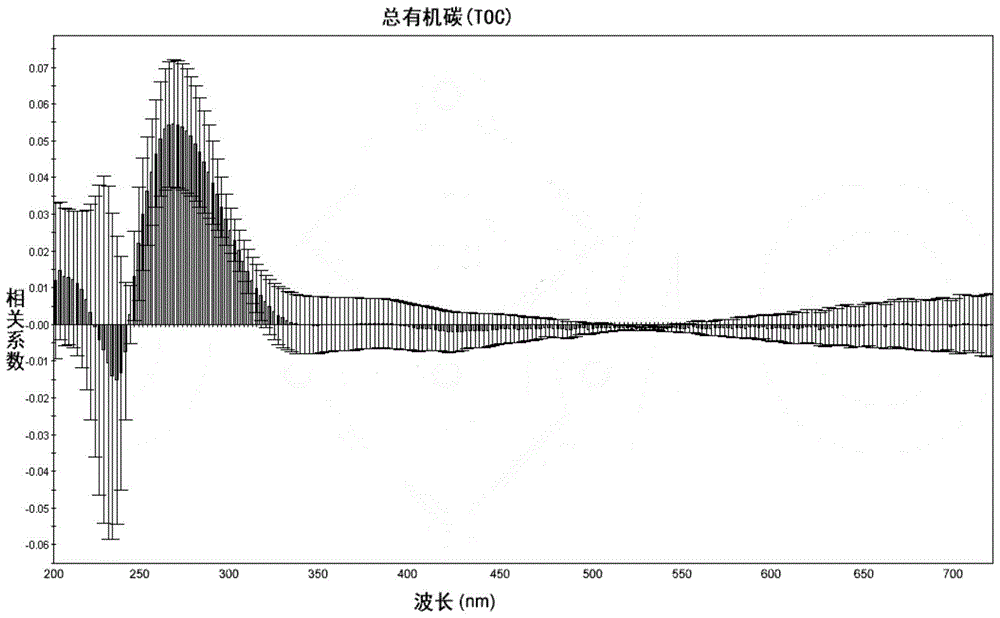

A water quality multi-indicator detection method based on ultraviolet-visible absorption spectroscopy

InactiveCN104034684BBig amount of dataAvoid situations that cannot comprehensively reflect multiple water quality indicatorsColor/spectral properties measurementsUltravioletWater quality

The invention relates to a water quality multi-index detection method based on ultraviolet-visible absorption spectrum, which comprises the following steps: 1) establishing a water quality algorithm model including each water quality index; 2) measuring and obtaining the ultraviolet-visible absorption spectrum of the water body to be tested; 3) According to the water quality algorithm model of the water body to be measured and the ultraviolet-visible absorption spectrum of the water body to be measured, calculate the preliminary calculation value of each water quality index in the water body to be measured; 4) perform the preliminary calculation value of each water quality index in the water body to be measured Local calibration to obtain the test results corresponding to each water quality index; 5) compare the obtained test results corresponding to each water quality index with the relevant water quality standards of each water quality index, and judge whether the water quality to be tested exceeds the standard and give an early warning. The invention measures the ultraviolet-visible full-wavelength absorption spectrum of the water body, and combines the water quality algorithm model and correction parameters to simultaneously calculate various water quality indicators in the water. Therefore, the present invention can be widely used in the monitoring and early warning mainly applicable to the process control of various surface water, various sewage, drinking water, sewage and water supply treatment process.

Owner:北京金达清创环境科技有限公司 +1

Graphical process variable trend monitoring for a process control system

ActiveCN105144011ANavigation Prediction and EfficientElectric testing/monitoringInput/output processes for data processingGraphicsDrill down

A process control monitoring system for a process control plant uses graphic trend symbols to assist in detecting and monitoring trends of process variables within the process control plant. A graphic display application within the process control monitoring system may implement and display each graphic trend symbol to graphically indicate or encapsulate current trend and value information of a process variable within the process control plant. The graphic display application may display the graphic trend symbol in a spatially realistic location within a graphical representation of the process control plant while maintaining the hierarchical structure or each hierarchical level of the process plant. The graphic display application may also include a zoom feature that enables a user to quickly drill down through tend data to obtain more information and to support problem identification and diagnosis tasks.

Owner:FISHER-ROSEMOUNT SYST INC

Dynamically extensible control system

ActiveUS20210302946A1Reduced flexibilityImprove performanceTechnology managementResourcesControl systemProcess engineering

The systems and methods described provide improved process control operating range and capabilities and integrate process control monitoring and management with broader process automation (PA) systems process management, extending the real-time operation and control of a process control system to process handling of a PA system, and extending PA-style process management by adding real-time process controls and monitoring, and adding new functionality by permitting management of these processes to externally defined completion goals. This combination provides new functionality in dynamically determined process flexibility, extended operating range and extended process recipe definition capabilities for process control systems using this technology, and provides improved error recovery and exception handling of traditional PA systems.

Owner:6TH STREET INC

Process control monitors for interferometric modulators

InactiveCN101027597ASemiconductor/solid-state device detailsSolid-state devicesSoftware engineeringOptical measurements

The invention discloses process control monitors are disclosed that are produced using at least some of the same process steps used to manufacture a MEMS device. Analysis of the process control monitors can provide information regarding properties of the MEMS device and components or sub-components in the device. This information can be used to identify errors in processing or to optimize the MEMS device. In some embodiments, analysis of the process control monitors may utilize optical measurements.

Owner:IDC LLC

Graphical process variable trend monitoring with zoom features for use in a process control system

ActiveUS10180681B2Assist in detectingEasy to distinguishProgramme controlElectric testing/monitoringGraphicsDrill down

A process control monitoring system for a process control plant uses graphic trend symbols to assist in detecting and monitoring trends of process variables within the process control plant. A graphic display application within the process control monitoring system may implement and display each graphic trend symbol to graphically indicate or encapsulate current trend and value information of a process variable within the process control plant. The graphic display application may display the graphic trend symbol in a spatially realistic location within a graphical representation of the process control plant while maintaining the hierarchical structure or each hierarchical level of the process plant. The graphic display application may also include a zoom feature that enables a user to quickly drill down through tend data to obtain more information and to support problem identification and diagnosis tasks.

Owner:FISHER-ROSEMOUNT SYST INC

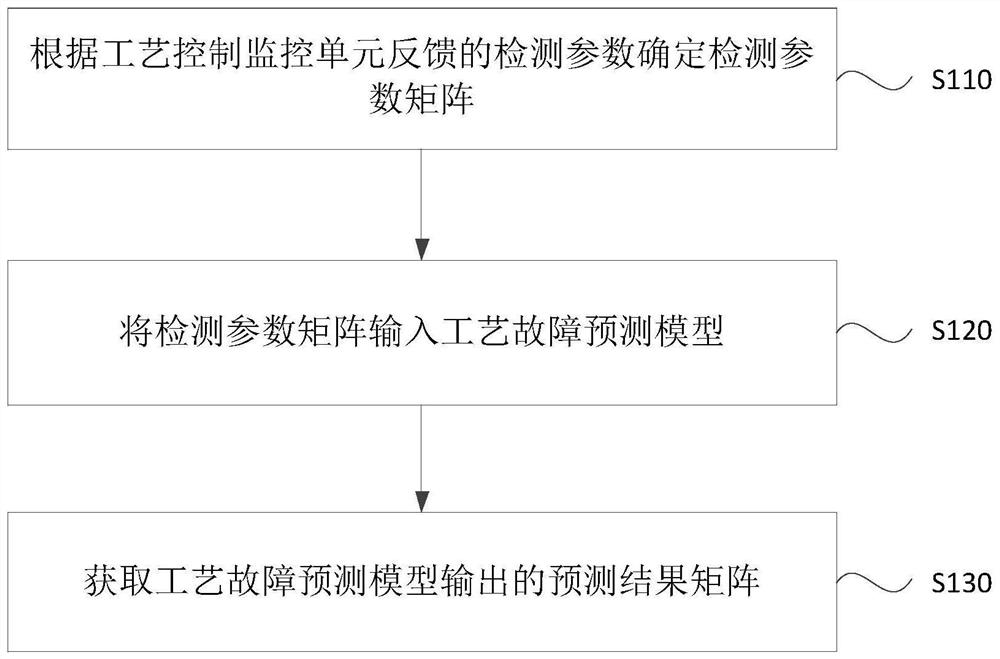

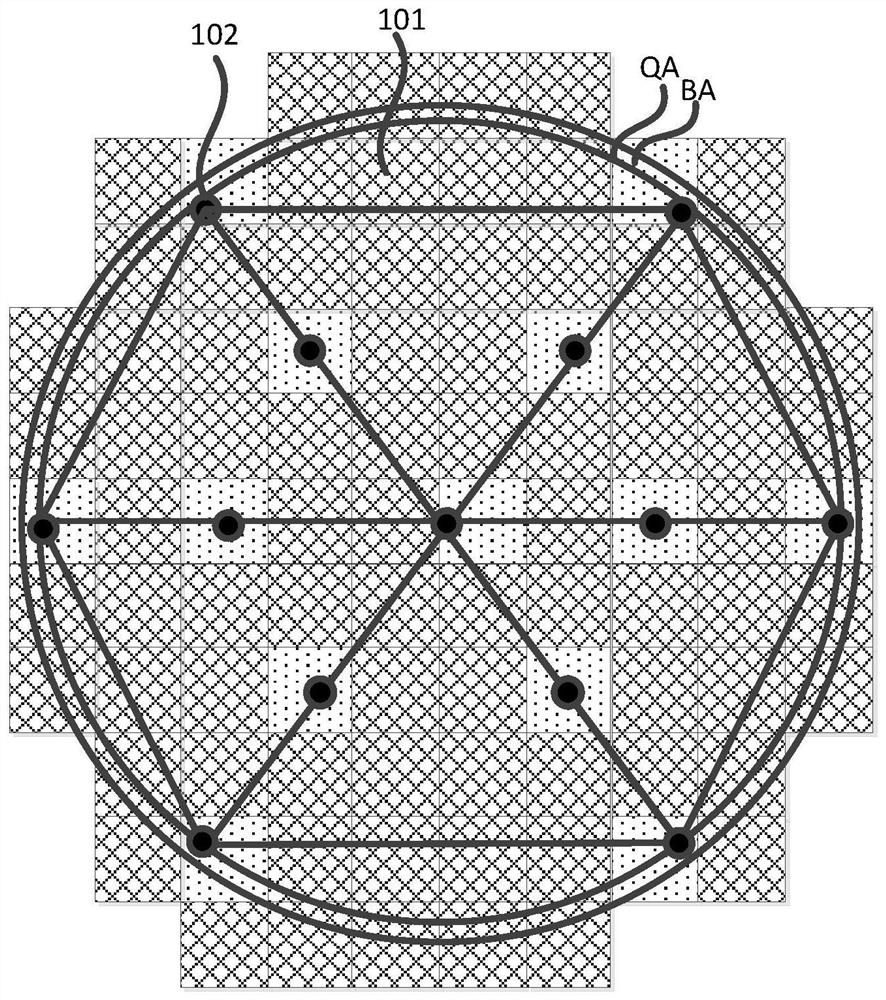

Wafer process fault prediction method and device, electronic equipment and storage medium

PendingCN113553795AImprove production efficiencySolve process problemsDesign optimisation/simulationCAD circuit designWaferProcess engineering

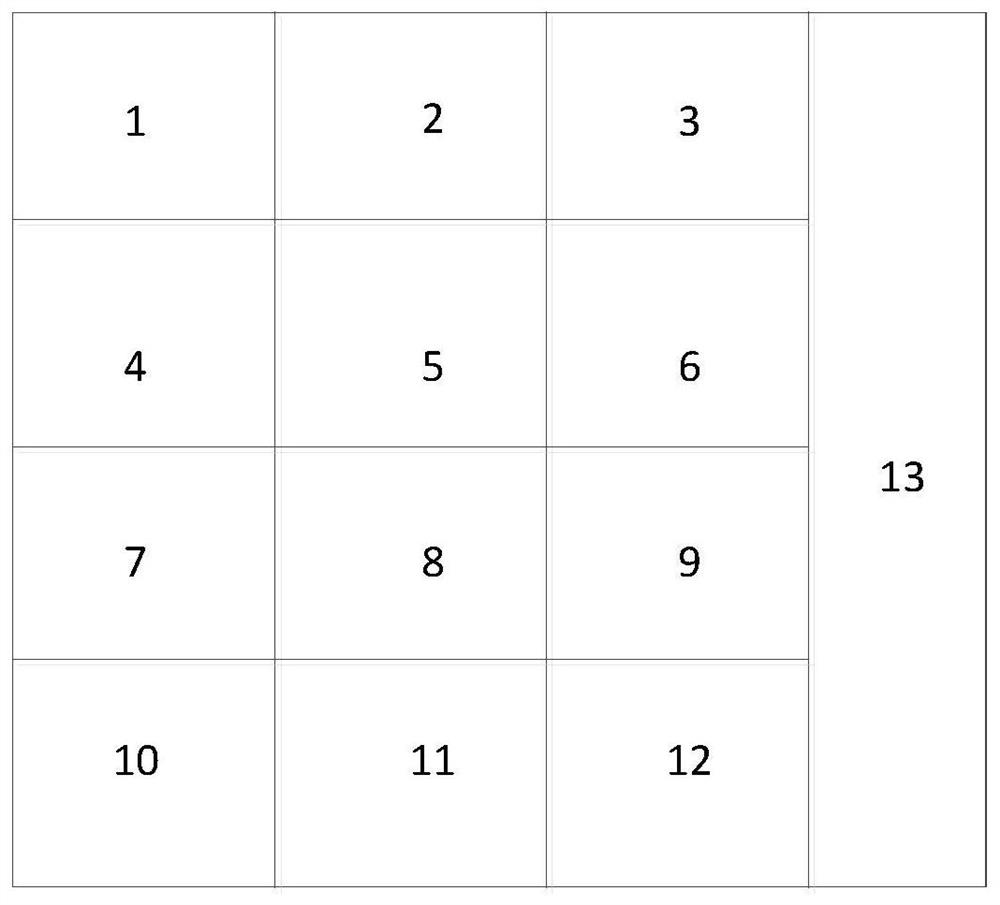

The embodiment of the invention discloses a wafer process fault prediction method and device, electronic equipment and a storage medium. The method comprises the following steps: determining a detection parameter matrix according to detection parameters fed back by a process control monitoring unit; inputting the detection parameter matrix into a process fault prediction model; and obtaining a prediction result matrix output by the process fault prediction model. The wafer comprises a device placing area, the center of the device placing area, the vertex of an internally tangent N-polygon of the device placing area and the midpoint of the connecting line of the vertex and the center are used as reference points, the wafer further comprises a plurality of photomask areas, and the photomask areas where the reference points are located are provided with process control monitoring units; the prediction result matrix comprises a plurality of first elements, the preparation process of the wafer comprises a plurality of process steps, and different first elements are used for representing the probability of faults in different process steps. According to the technical scheme provided by the embodiment of the invention, the wafer detection time can be shortened, and the process fault prediction of each process step in the wafer preparation process can be realized.

Owner:SUZHOU CREALIGHTS TECH

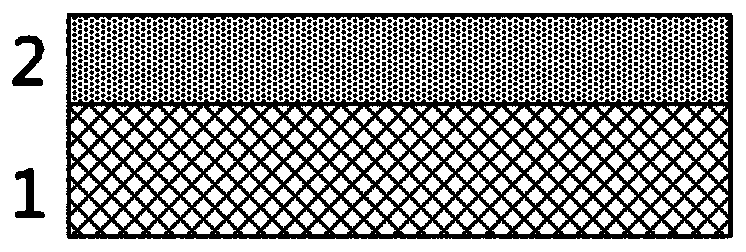

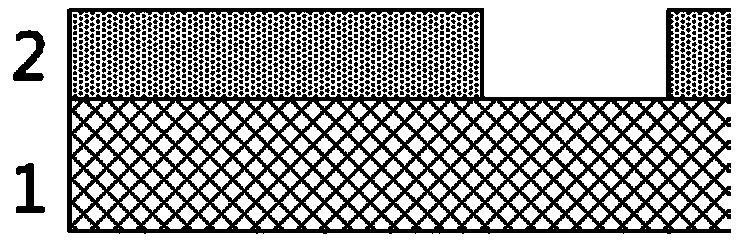

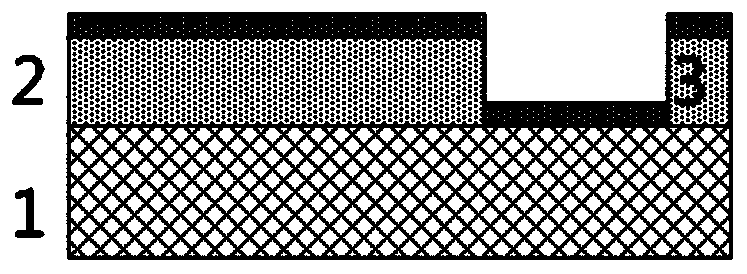

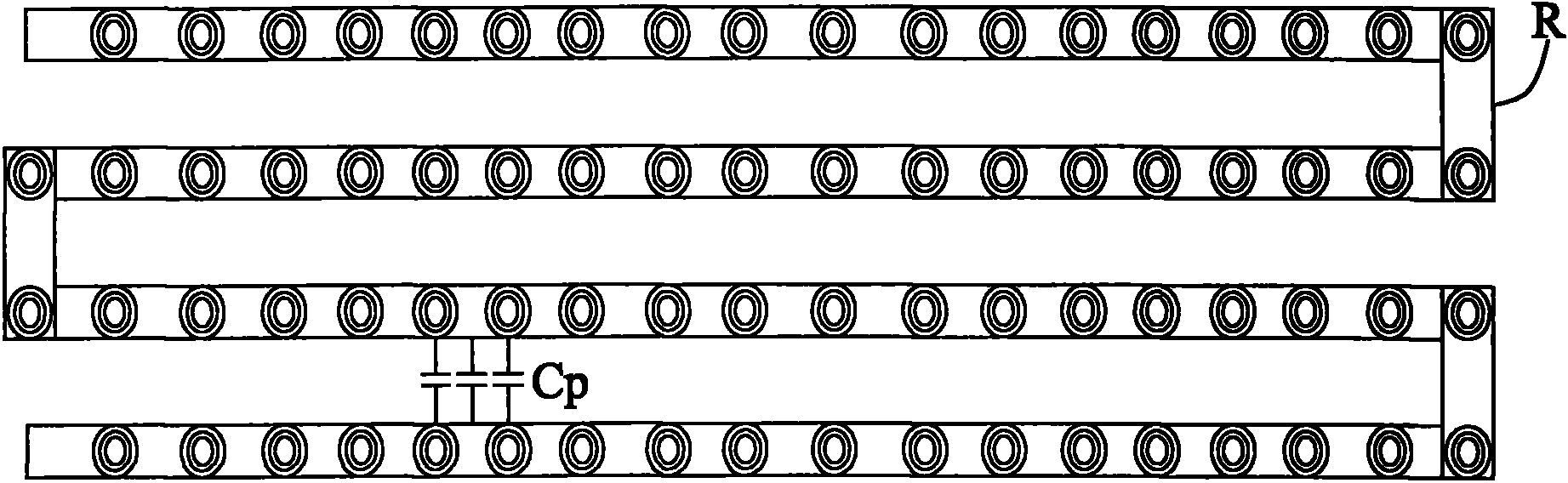

Nanocrystalline deposition density process control monitoring method, module and manufacturing method thereof

ActiveCN102593103BProcess compatibleNo extra costSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsCapacitanceEngineering

The invention provides a process control monitoring method of nanocrystalline deposition density, a module thereof and a manufacturing method thereof. The process control monitoring module comprises a first module and a second module which are formed on a semiconductor substrate. The first module comprises a bottom oxide layer, a nanocrystalline layer, a top oxide layer and a polysilicon layer from the bottom up. The second module comprises a top oxide layer and a polysilicon layer from the bottom up. Through testing the capacitance of the first module and the second module of the process control monitoring module, the density of deposited nanocrystalline can be obtained, thus process stability in a nanocrystalline deposition process can be monitored, and abnormal condition of nanocrystalline particle deposition process can be fed back timely.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

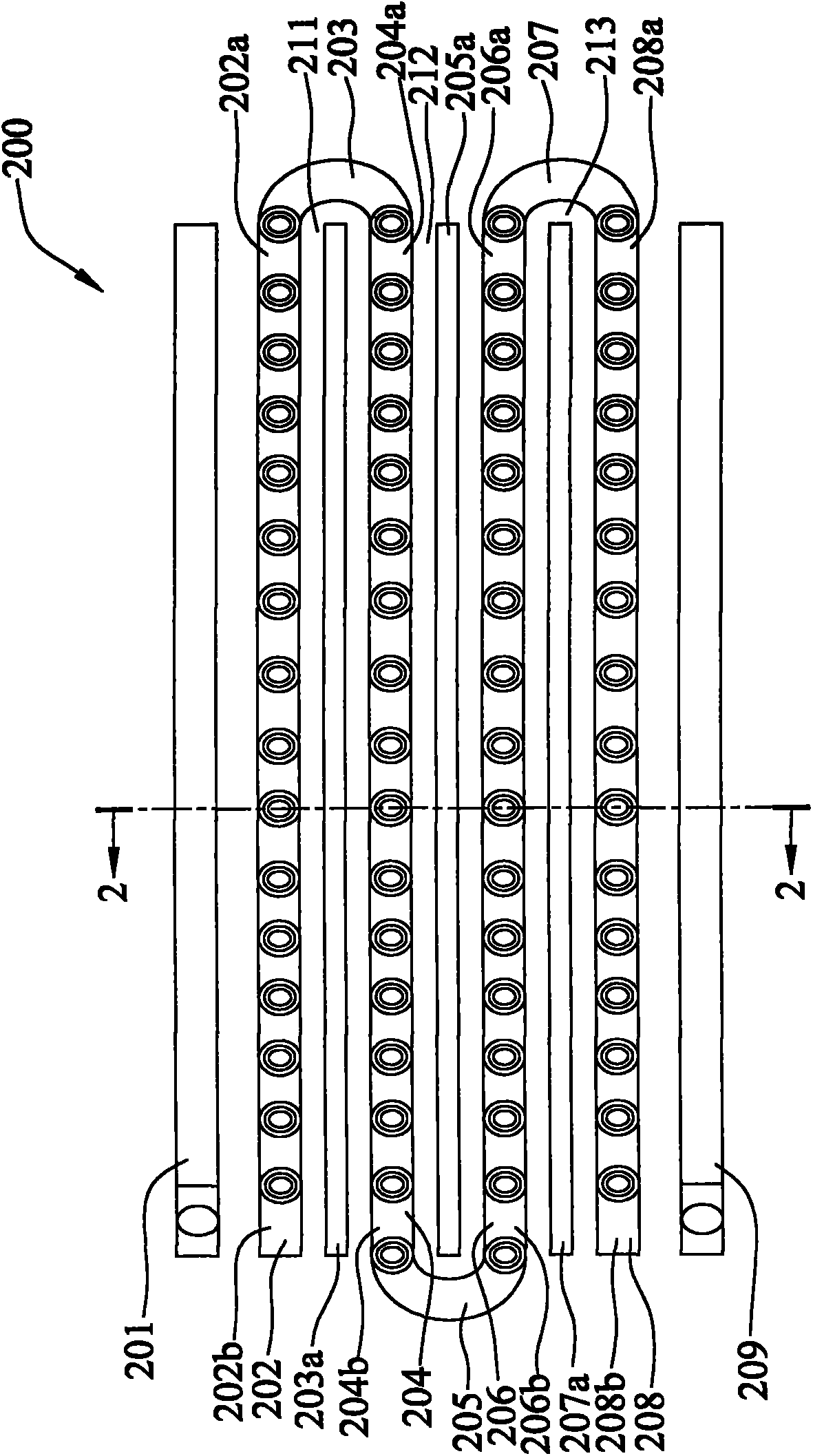

Circuit unit structure for process monitoring

ActiveCN102832202AAvoid or reduce edge parasitic capacitance CpImprove correct assessmentSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceCoupling

A circuit unit structure for process monitoring, especially a circuit unit structure applied to advance integrated circuit processing for integrated circuit testing and process monitoring, compared with conventional circuit unit structure, comprises a plurality of pore chains, a floating metal layer and an arc-shaped connection part, and is capable of notably reducing point discharge and radio frequency coupling or crosstalk effect during interflow or radio frequency testing processes, and preventing a too huge parasitic capacitance Cp from existing among the pore chains, thereby preventing assessment errors of via-hole resistance values from occurring, and further promoting reliability degree of the overall integrated circuit processing and testing.

Owner:SILICONWARE PRECISION IND CO LTD

Navigating within graphical depiction of process control plant

ActiveCN105051635ANavigation Prediction and EfficientProgramme controlComputer controlGraphicsGraphical projection

A process control monitoring method uses a navigation pane for navigating within a graphical depiction of a process control plant. The navigation pane that includes a unit selection area and an equipment selection area, wherein (i) the unit selection area includes one or more unit selector icons that correspond to one or more units in the graphical depiction of the process control plant, (ii) the equipment selection area includes one or more equipment selector icons that correspond to one or more equipment in the graphical depiction of the process control plant, (iii) each unit in the process control plant includes one or more equipment in the process control plant, and (iv)each unit selector icon is associated with one or more equipment items selector icons based on the included one or more equipment in the process control plant associated with the unit that corresponds to the unit selector icon. In response to receiving a selection of a first unit selector icon, one or more equipment selector icons in the equipment area associated with a first unit in the process control plant that corresponds to the selected first unit selector icon are displayed, wherein (i) the one or more equipment selector icons associated with the selected first unit selector icon are displayed in the equipment selection area and (ii) the one or more non-selected unit selector icons remain displayed in the unit selection area. Moreover, one or more equipment in the graphical depiction of the process control corresponding to the first unit selector icon is displayed.

Owner:FISHER-ROSEMOUNT SYST INC

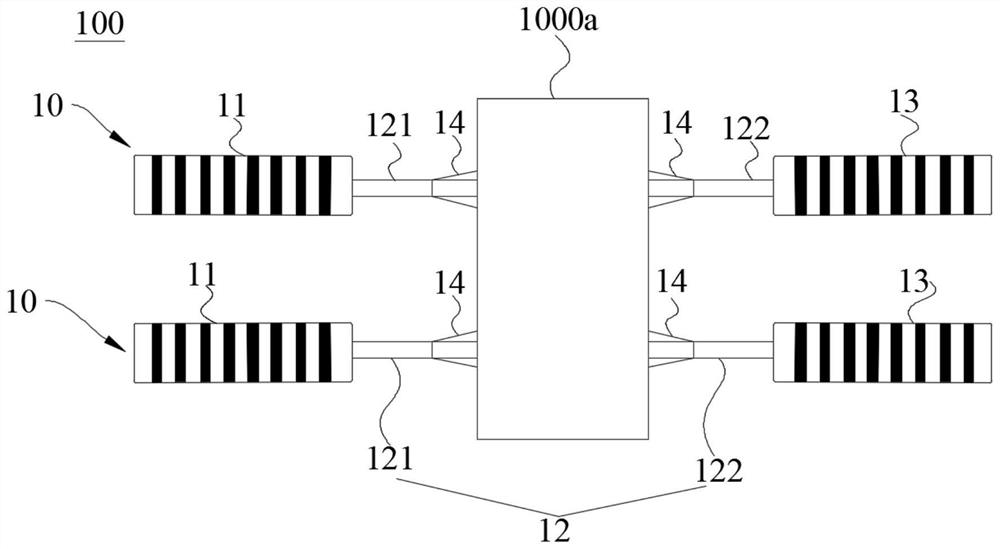

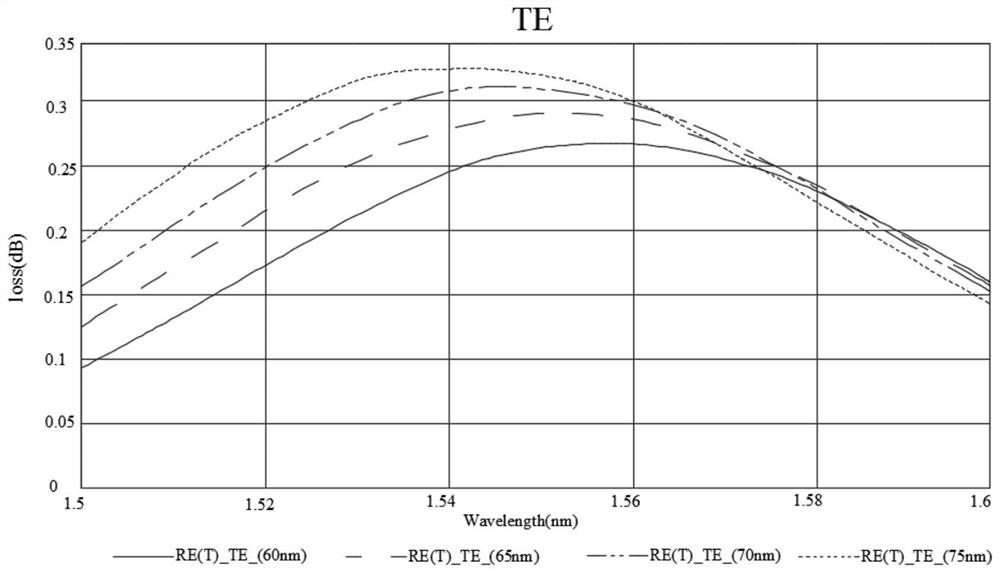

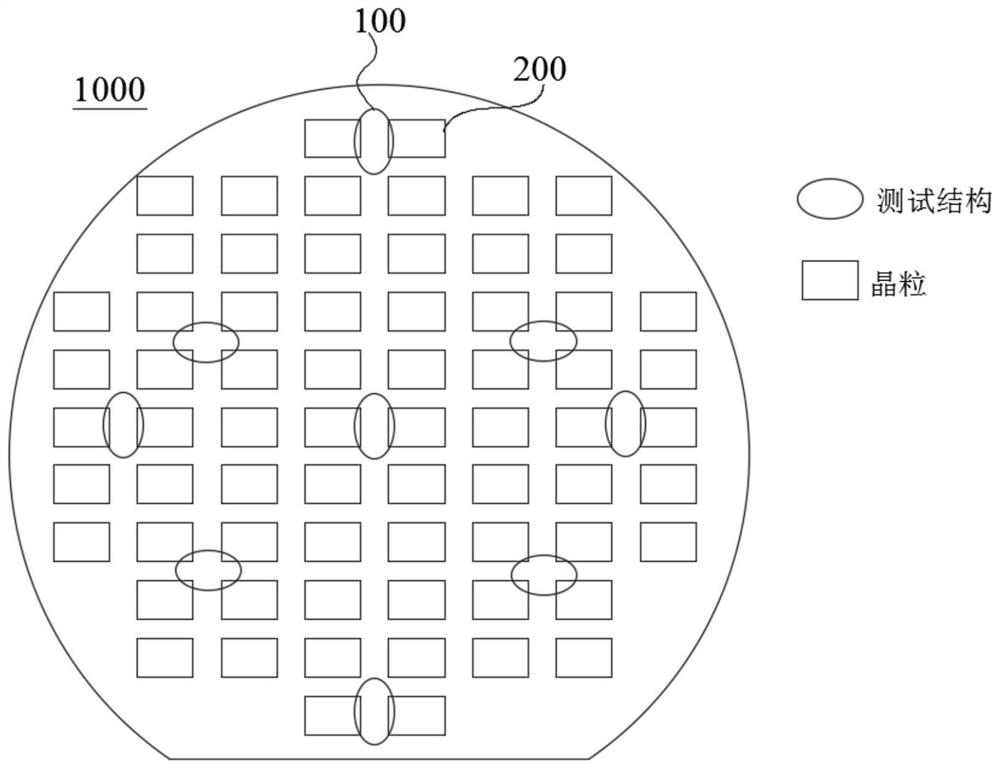

Test structure, wafer and manufacturing process control monitoring method forwafer

ActiveCN112198589ARealize manufacturing process control monitoringImprove yieldSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsWaferOutput coupler

The embodiment of the invention provides a test structure, a wafer and a manufacturing process control monitoring method for a wafer. The test structure comprises at least one test unit, the test unitcomprises an input coupler, a waveguide and an output coupler; the waveguide, the input coupler and the output coupler are formed through a manufacturing process; polarized light with different wavelengths enters the input coupler, is transmitted through the waveguide and then is emitted out from the output coupler. Whether a mask plate is aligned in the exposure process and whether the etching depth in the etching process meets the requirements or not are determined by acquiring spectral characteristic curves of the polarized light with different wavelengths, so that the consistency and stability of the manufacturing process are ensured, the control and monitoring of the manufacturing process of the wafer are realized, and the yield of a photon integrated chip or a photoelectron integrated chip is improved.

Owner:WUHAN OPTICAL VALLEY INFORMATION OPTOELECTRONICS INNOVATION CENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com