Test structure, wafer and manufacturing process control monitoring method forwafer

A technology for testing structure and manufacturing process, which is applied to the photoengraving process of the pattern surface, the exposure device of the photoengraving process, the testing/measurement of semiconductor/solid-state devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

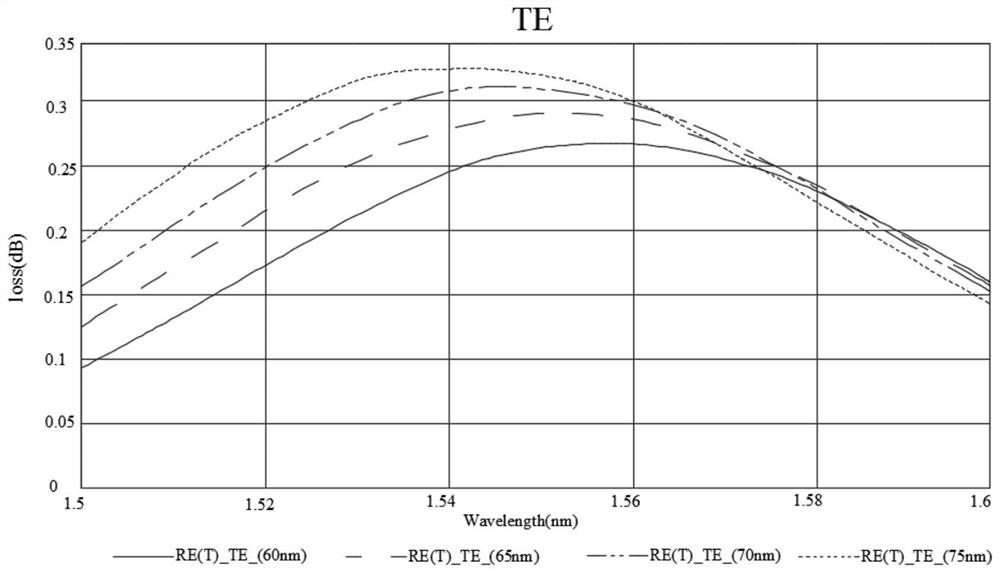

[0026] It should be noted that, in the case of no conflict, the embodiments in the application and the technical features in the embodiments can be combined with each other. Undue Limitation of This Application. Among them, nm is the SI unit of nanometer, and dB is the SI unit of decibel. The present application will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

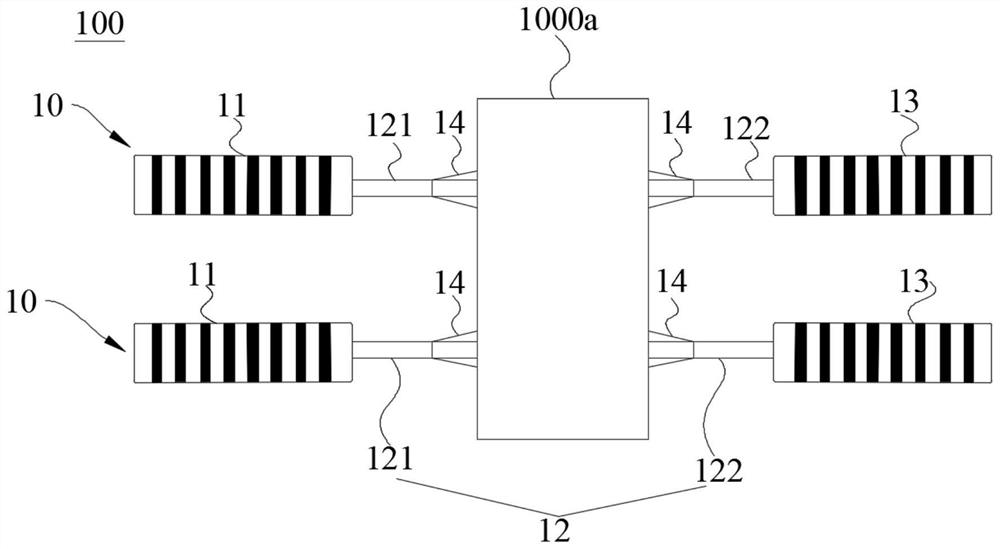

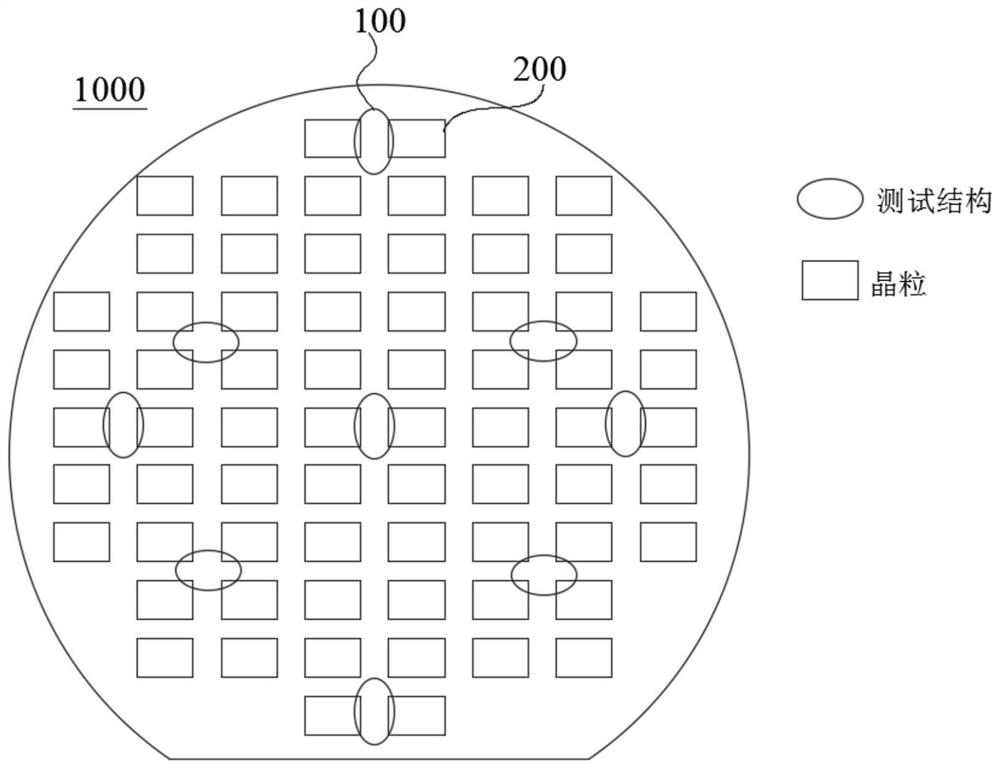

[0027] See figure 1 , the embodiment of the present application provides a test structure for wafer manufacturing process control monitoring, the test structure 100 includes at least one test unit 10, the test unit 10 includes an input coupler 11, a waveguide 12 and an output coupler 13, the waveguide 12 , the input coupler 11 and the output coupler 13 are all formed through a manufacturing process; polarized light of different wavelengths is injected into the input coupler 11 , transmitted through the waveguide 12 , and then emitted from the output cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com