Polar plate for battery, manufacturing method of polar plate, polar plate group with polar plates and lead storage battery

A pole plate and battery technology, which is applied in electrode manufacturing, lead-acid battery, lead-acid battery electrode and other directions, can solve the problems of increasing the distance between the ointment plate and the pole plate, difficult to continue to increase the capacity, and reducing the battery life, etc. Possibility of short circuit, effect of improving charging efficiency and improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] (1) Manufacture of positive plate

[0077] Raw material lead powder (a mixture of lead and lead oxide), water, and dilute sulfuric acid were kneaded in a weight ratio of about 100:12:14 to obtain a positive electrode paste as a positive electrode active material.

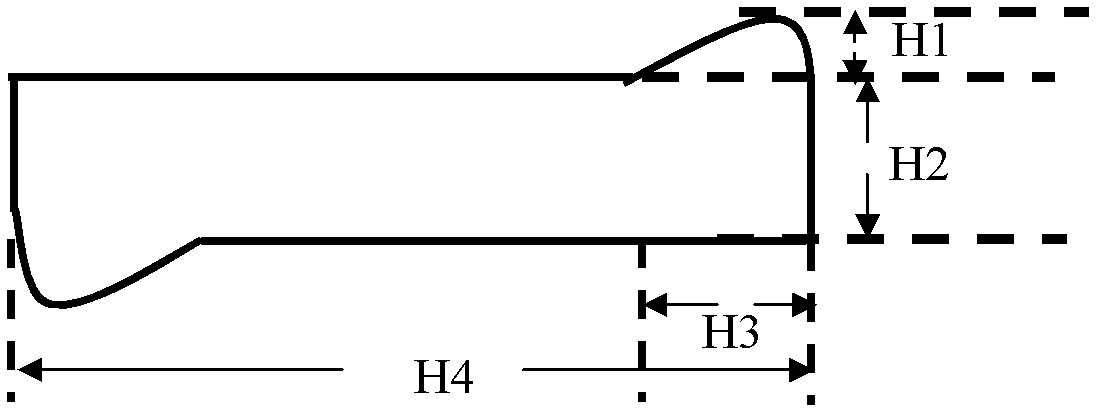

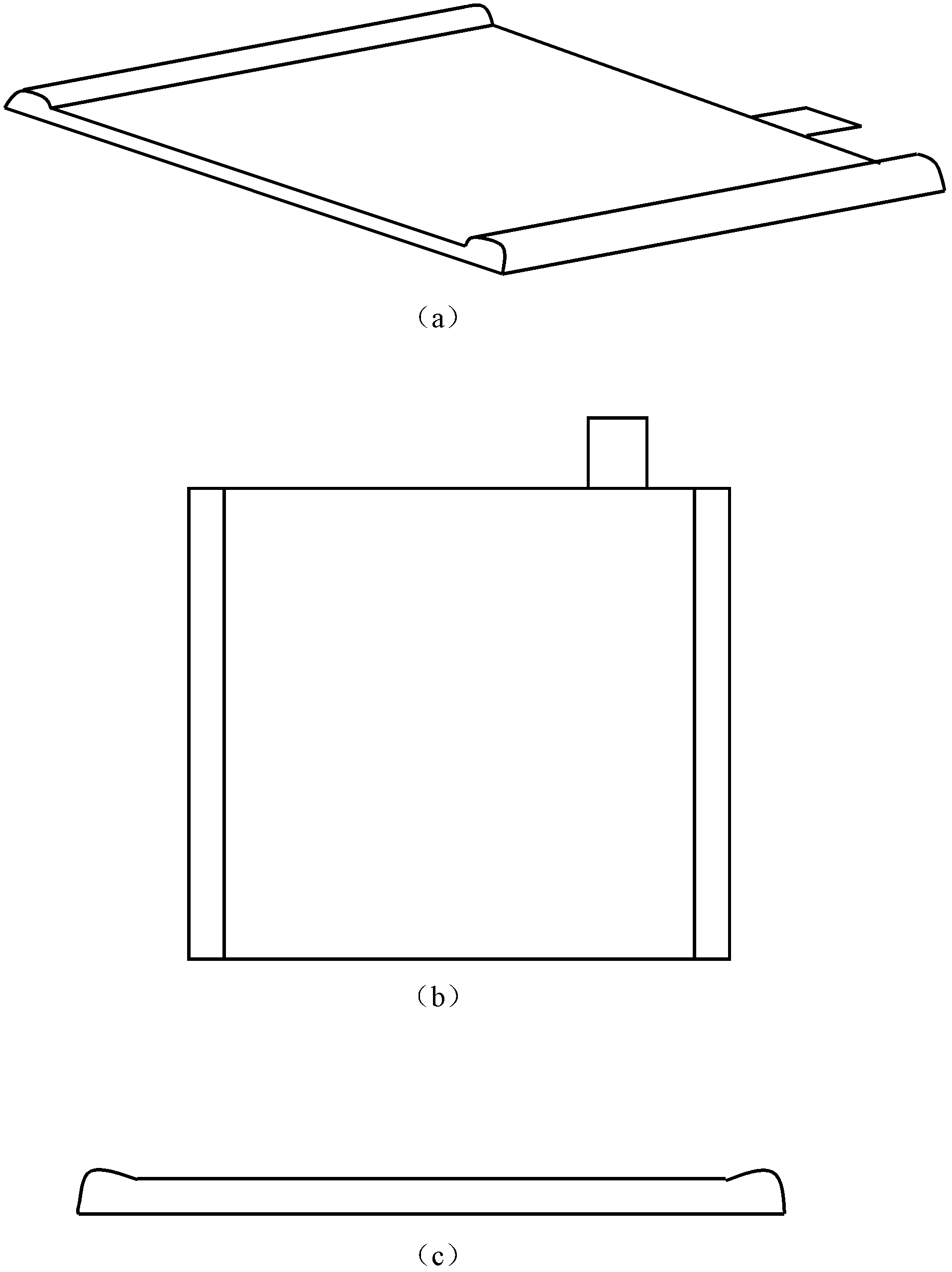

[0078] On the other hand, a lead strip comprising a Pb alloy containing about 0.07 mass % Ca and about 1.3 mass % Sn obtained by casting was extruded to a thickness of 1.3 mm. Such as Figure 4 (a) and Figure 4 Shown in (b), at first, carry out cutting and drawing process, use reciprocating stamping die to repeatedly carry out stamping to lead band 27, while forming a plurality of slits along the length direction of lead band, this slit is along with lead band surface The vertical direction is developed to form a mesh sheet having a grid 25 formed by interlacing a plurality of ruled lines. Then, the above-mentioned mesh sheet is shaped by a pair of rollers of a shaping mold to obtain an expanded mesh. Then...

Embodiment 2~4

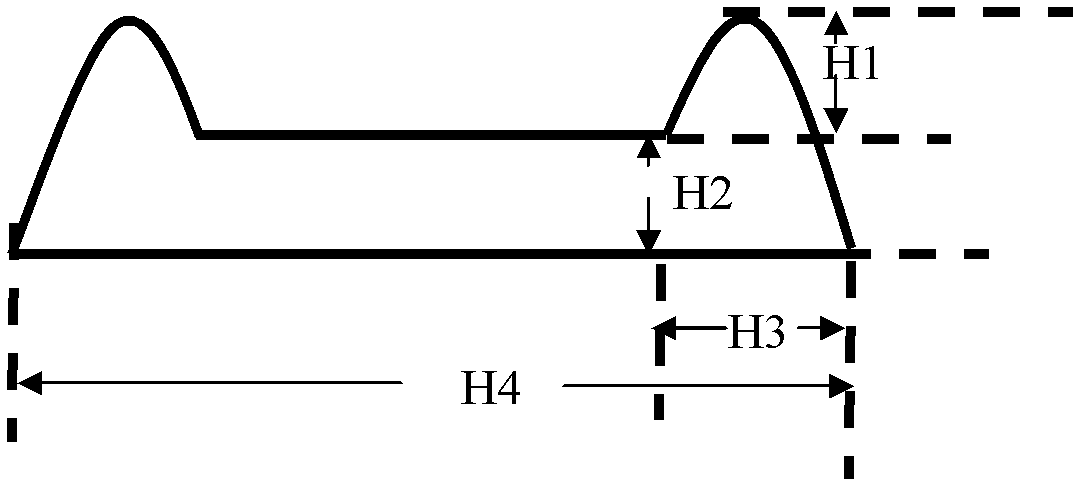

[0098] In addition to increasing the blade angle of the hobbing cutter used in the cutting process of the positive plate to 50° to 60°, and increasing the thickness ratio H1 / H2 of the resulting protrusion to 4% to 6%, the others are all in accordance with the embodiment. 1 The same setting and process method are used to make the plate group and the lead storage battery.

Embodiment 5

[0100] Except that the punching method was adopted in the cutting process of the positive plate and the negative plate, the other settings and processes were the same as those in Example 4 to prepare the plate set and the lead-acid battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Blade angle | aaaaa | aaaaa |

| Blade angle | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com