Synthesis and application of restricted access filler having inner surface with inverting performance

An inner surface, limited access technology, which is applied to the synthesis and application of the inner surface reversed-phase limited-access packing, can solve the problems of low accuracy and precision, consumption of reagents, large sample volume, etc., and achieve good reversed-phase performance , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

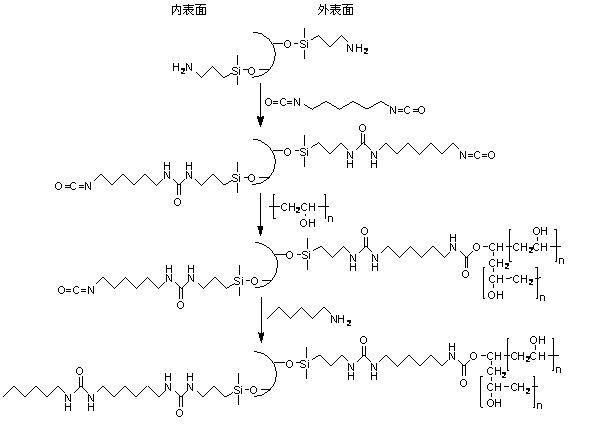

[0036] Example 1 The reverse-phase restricted-access filler on the inner surface, the restricted-access filler is a restricted-access filler with protein exclusion properties on the outer surface and reverse-phase performance on the inner surface, which has the following structural formula,

[0037]

[0038] where n=1955.

[0039] The synthesis method of the inner surface anti-phase restricted entry filler comprises the following steps:

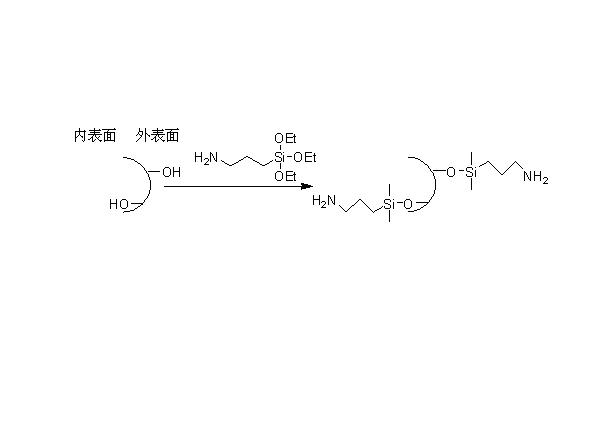

[0040] ⑴ Synthesis of aminopropyl alkylated silica gel (APS) (see figure 1 ):

[0041] First, the porous silica gel with a particle size of 5 μm was activated by hydrochloric acid with a mass concentration of 3.65%, and then placed in a 250 mL three-necked bottle and dried in a BPZ-6033LC vacuum oven at 180 °C for 5 h to obtain activated silica gel.

[0042] Then, add activated silica gel to anhydrous toluene and reflux at a temperature of 115 ° C, and remove residual moisture azeotropically in N 2 Under protection, 3-aminopropyltriet...

Embodiment 2

[0064] Example 2 The reverse-phase restricted-access filler on the inner surface, the restricted-access filler is a restricted-access filler with protein exclusion properties on the outer surface and reverse-phase performance on the inner surface, which has the following structural formula,

[0065]

[0066] where n=500.

[0067] The synthesis method of the inner surface anti-phase restricted entry filler comprises the following steps:

[0068] ⑴ Synthesis of APS:

[0069] First, the porous silica gel with a particle size of 5 μm was activated by hydrochloric acid with a mass concentration of 3.65%, and then placed in a 250 mL three-necked bottle and dried in a BPZ-6033LC vacuum oven at 150 °C for 6 h to obtain activated silica gel.

[0070] Then, the activated silica gel was added to anhydrous toluene to reflux at a temperature of 110 ° C, and the residual moisture was removed by azeotropy in N 2 Under protection, 3-aminopropyltriethoxysilane was added, and the DF-101S...

Embodiment 3

[0083] Example 3 The reverse-phase restricted-access filler on the inner surface, the restricted-access filler is a restricted-access filler with protein exclusion properties on the outer surface and reverse-phase performance on the inner surface, which has the following structural formula,

[0084]

[0085] where n=2300.

[0086] The synthesis method of the inner surface anti-phase restricted entry filler comprises the following steps:

[0087] ⑴ Synthesis of APS:

[0088] First, the porous silica gel with a particle size of 5 μm was activated by hydrochloric acid with a mass concentration of 3.65%, and then placed in a 250 mL three-necked bottle and dried in a BPZ-6033LC vacuum oven at 200 °C for 4 h to obtain activated silica gel.

[0089] Then, add activated silica gel to anhydrous toluene and reflux at a temperature of 120°C, and remove residual moisture azeotropically under N 2 Under protection, 3-aminopropyltriethoxysilane was added, and the DF-101S collector typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com