Nano silver-titanium dioxide loaded porous cordierite foamed ceramic catalyst and preparation

A technology of titanium dioxide and foam ceramics, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, alkali metal oxides/hydroxides, etc., to improve photocatalytic efficiency, large adsorption capacity, The effect of a large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

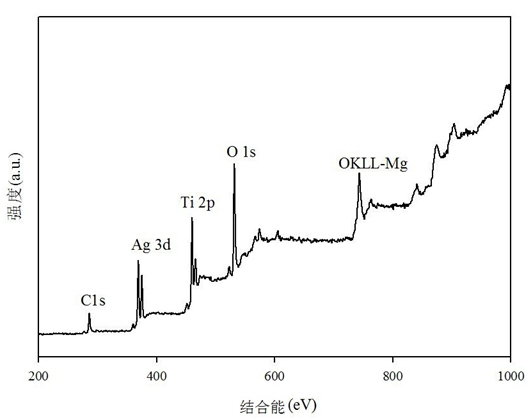

Image

Examples

Embodiment 1

[0018] The preparation method and preparation steps of the nano-silver-titania supported porous cordierite foam ceramic catalyst are:

[0019] (1) Disperse the purchased P25 titanium dioxide in water, the concentration of titanium dioxide is 1000 mg / L, and sonicate for 5 minutes. In the titanium dioxide suspension, Ag:Ti atomic molar ratio is 1:20, add silver nitrate, and stir for 30 minutes , finally add the sodium borohydride of the same molar amount as silver nitrate in the above-mentioned mixed solution, and adjust the pH value of the solution to 10.0 with ammonia, filter, wash and dry after stirring for 30 minutes, and finally obtain nano-silver-titanium dioxide particles;

[0020] (2) Add 500 mg of nano-silver-titanium dioxide particles into 1 liter of water, and stir until the nano-silver-titanium dioxide particles are uniformly dispersed in the water to obtain a nano-silver-titanium dioxide suspension with a concentration of 500 mg / L;

[0021] (3) Immerse the cordier...

Embodiment 2

[0024] The preparation method and preparation steps of the nano-silver-titania supported porous cordierite foam ceramic catalyst are:

[0025] (1) Disperse the purchased P25 titanium dioxide in water, the concentration of titanium dioxide is 1000 mg / L, and sonicate for 5 minutes. In the titanium dioxide suspension, Ag:Ti atomic molar ratio is 1:20, add silver nitrate, and stir for 30 minutes , finally add the sodium borohydride of the same molar amount as silver nitrate in the above-mentioned mixed solution, and adjust the pH value of the solution to 10.0 with ammonia, filter, wash and dry after stirring for 30 minutes, and finally obtain nano-silver-titanium dioxide particles;

[0026] (2) Add 500 mg of nano-silver-titanium dioxide particles into 1 liter of water, and stir until the nano-silver-titanium dioxide particles are uniformly dispersed in the water to obtain a nano-silver-titanium dioxide suspension with a concentration of 500 mg / L;

[0027] (3) Immerse the cordier...

Embodiment 3

[0030] The preparation method and preparation steps of the nano-silver-titania supported porous cordierite foam ceramic catalyst are:

[0031] (1) Disperse the purchased P25 titanium dioxide in water, the concentration of titanium dioxide is 1000 mg / L, and sonicate for 5 minutes. In the titanium dioxide suspension, Ag:Ti atomic molar ratio is 1:20, add silver nitrate, and stir for 30 minutes , finally add the sodium borohydride of the same molar amount as silver nitrate in the above-mentioned mixed solution, and adjust the pH value of the solution to 10.0 with ammonia, filter, wash and dry after stirring for 30 minutes, and finally obtain nano-silver-titanium dioxide particles;

[0032] (2) Add 500 mg of nano-silver-titanium dioxide particles into 1 liter of water, and stir until the nano-silver-titanium dioxide particles are uniformly dispersed in the water to obtain a nano-silver-titanium dioxide suspension with a concentration of 500 mg / L;

[0033] (3) Immerse the cordierit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com