Method for improving machining efficiency of micro-channel preparation through femtosecond laser

A technology of femtosecond laser and processing efficiency, which is applied in the field of femtosecond laser application, can solve the problems of low efficiency, reduce the controllability of precision processing, and the processing speed is only 0.3μm/, and achieve the effect of improving the preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The femtosecond laser system 1 uses a laser produced by Spectrum Physics in the United States. The laser wavelength is 800nm, the pulse width is 50 femtoseconds, the repetition frequency is 1KHz, the maximum energy of a single pulse is 3mJ, and the light intensity distribution is Gaussian and linearly polarized.

[0026] Test sample 9 is K9 glass with a thickness of 1.5 mm.

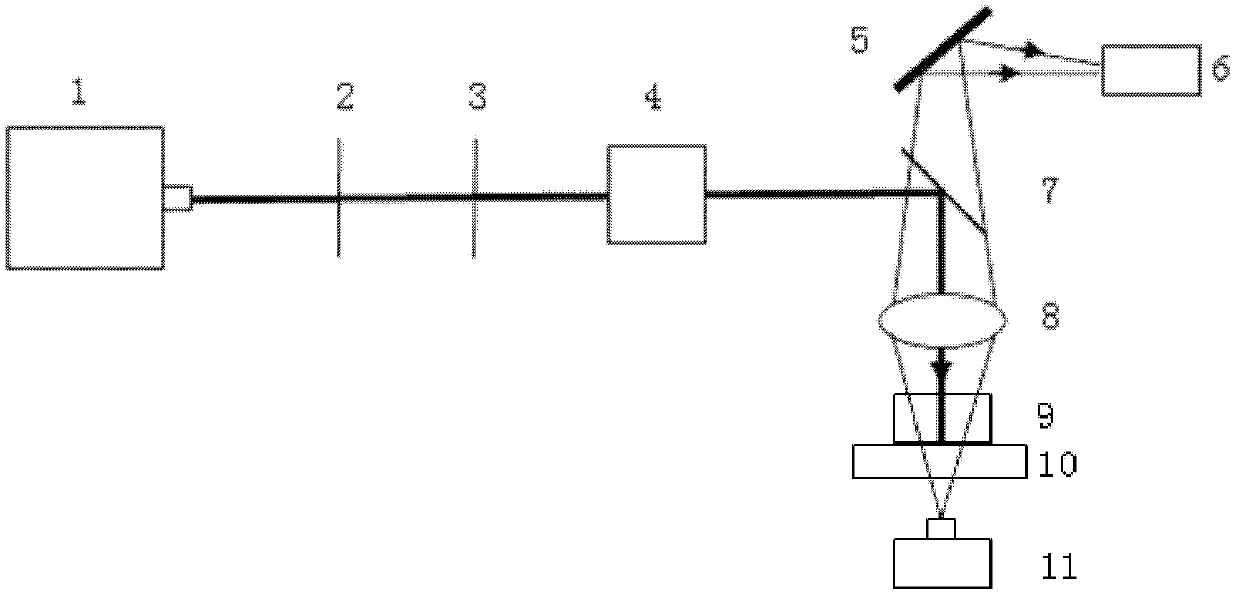

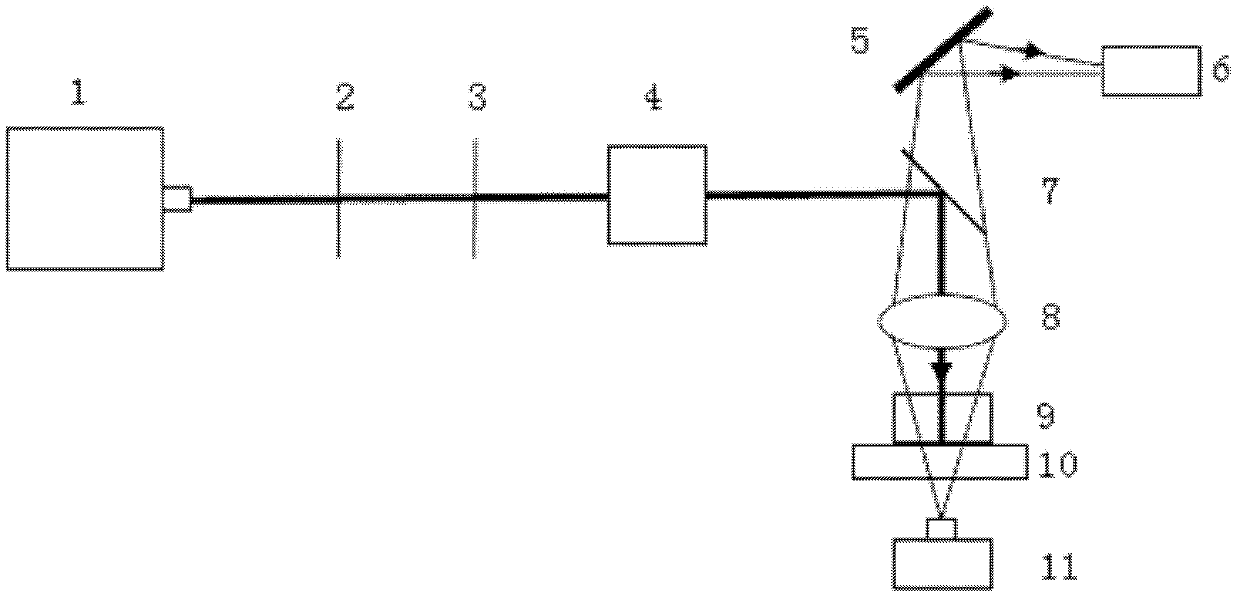

[0027] A method for improving the processing efficiency of microchannels prepared by femtosecond laser proposed by the present invention, the schematic diagram of the processing optical path is as follows figure 1 As shown, the specific processing steps are as follows:

[0028] Step 1: Use femtosecond laser system 1 to generate femtosecond pulse laser, use the combination of half-wave plate 2 and polarizer 3 to adjust the single pulse energy to 20 μJ, and modulate the traditional femtosecond laser into a pulse sequence through pulse shaper 4, the The sequence contains two sub-pulses with a pulse i...

Embodiment 2

[0034] The femtosecond laser system 1 uses a laser produced by Spectrum Physics in the United States. The laser wavelength is 800nm, the pulse width is 50 femtoseconds, the repetition frequency is 1KHz, the maximum energy of a single pulse is 3mJ, and the light intensity distribution is Gaussian and linearly polarized.

[0035] Test sample 9 is K9 glass with a thickness of 1.5 mm.

[0036] A method for improving the processing efficiency of microchannels prepared by femtosecond laser proposed by the present invention, the schematic diagram of the processing optical path is as follows figure 1 As shown, the specific processing steps are as follows:

[0037] Step 1: Use femtosecond laser system 1 to generate femtosecond pulse laser, use the combination of half-wave plate 2 and polarizer 3 to adjust the single pulse energy to 36 μJ, and modulate the traditional femtosecond laser into a pulse sequence through pulse shaper 4, the The sequence contains two sub-pulses with a pulse i...

Embodiment 3

[0043] The femtosecond laser system 1 uses a laser produced by Spectrum Physics in the United States. The laser wavelength is 800nm, the pulse width is 50 femtoseconds, the repetition frequency is 1KHz, the maximum energy of a single pulse is 3mJ, and the light intensity distribution is Gaussian and linearly polarized.

[0044] Test sample 9 was fused silica and had a thickness of 1.5 mm.

[0045] A method for improving the processing efficiency of microchannels prepared by femtosecond laser proposed by the present invention, the schematic diagram of the processing optical path is as follows figure 1 As shown, the specific processing steps are as follows:

[0046]Step 1: Use femtosecond laser system 1 to generate femtosecond pulse laser, use the combination of half-wave plate 2 and polarizer 3 to adjust the single pulse energy to 30 μJ, and modulate the traditional femtosecond laser into a pulse sequence through pulse shaper 4, the The sequence contains two sub-pulses with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com