Method for preparing nanometer molybdenum trioxide

A technology of nano-molybdenum trioxide and molybdenum trioxide, which is applied in the field of non-ferrous metal metallurgy, can solve problems such as long sublimation time, no industrial application, and influence on product purity, and achieve the effect of avoiding coagulation or agglomeration and fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

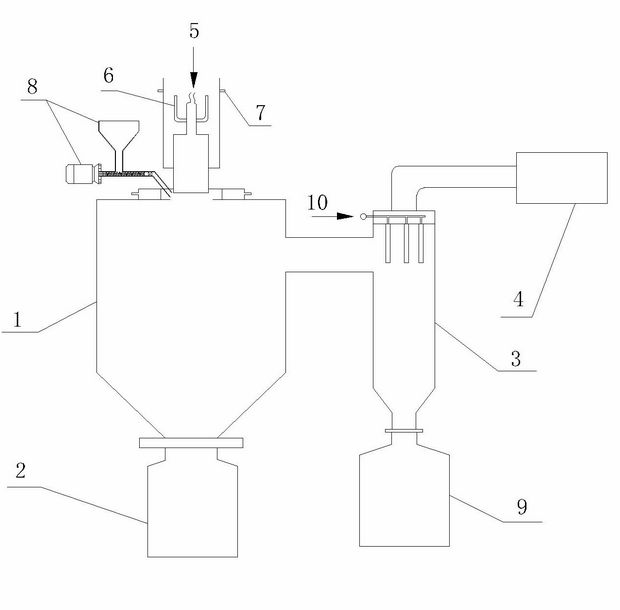

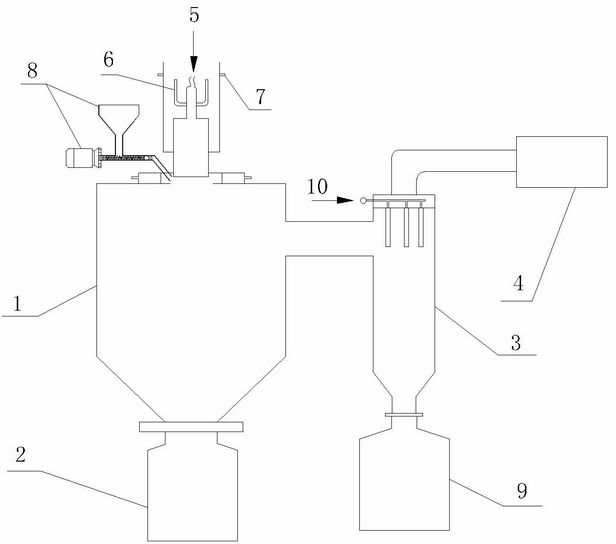

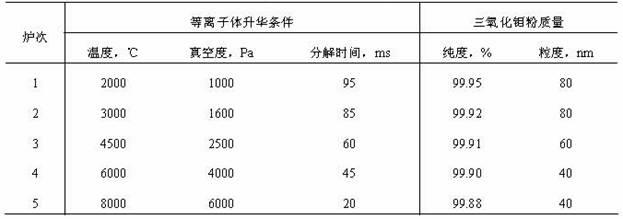

[0029] The process equipment arrangement for preparing nano molybdenum trioxide of the present invention is as follows figure 1 As shown, the sublimation is carried out in the plasma sublimation furnace 1, and the production equipment also includes a feeding device 8, a receiving device 9, a miscellaneous receiving device 2, a vacuum system 4, a cooling system 6 and a water-cooled collection device 3, etc.; the pure molybdenum trioxide The raw material powder is sent into the plasma sublimation furnace 1 through the feeding device 8, and sublimated in the 2000-10000°C plasma flow generated by the plasma gas 5 jet flame, and the operation time is 10-100ms; the molybdenum trioxide produced by sublimation is introduced into the water-cooled collection Device 3, use water as the quenching agent to quench, and the receiving device 9 collects to obtain nano-molybdenum trioxide; the vacuum system 4 controls the vacuum degree of the system at 10 3 ~10 5 Pa, the cooling system 6 is pr...

Embodiment 1

[0041] Raw material: pure molybdenum trioxide powder, its chemical composition is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com