Method for improving purity of acarbose

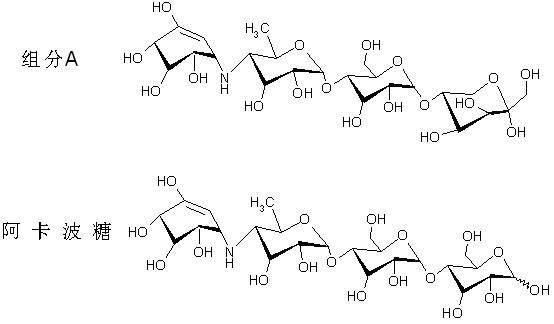

A technology of acarbose and purity, applied in the field of medicine, can solve problems such as unfavorable cost control, reduction of impurities, and large energy waste, so as to improve the safety and stability of medication, overcome the high content of impurities A, and simplify the process The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Prepare a pre-purified solution containing 93.52 grams of acarbose, wherein the impurity A content is 1.43%, put the aluminum oxide chromatography column on the liquid level, and use air pressure to pass the acarbose pre-purified solution into the alumina In the column, adjust the size of the outlet valve of the alumina column, control the flow rate of the outlet liquid to 0.5 BV / h, start to collect the outlet liquid from the second column volume, stop feeding the material, put the material liquid at normal pressure or compressed air, and then All remaining material was pressed out with deionized water. The collected outlet liquid is a low-impurity (A impurity) high-purity acarbose aqueous solution, which was detected by high-performance liquid chromatography, and 82.30 grams of pure acarbose was obtained, of which the content of A impurity was 0.58%, and the single-step yield reached 88%.

Embodiment 2

[0021] Example 2: Prepare a pre-purified solution containing 227.89 grams of acarbose, wherein the impurity A content is 1.36%, put the aluminum oxide column on the liquid level, and use air pressure to pass the acarbose pre-purified solution into the alumina column , adjust the size of the outlet valve of the alumina column, control the flow rate of the outlet liquid to 0.4 BV / h, start to collect the outlet liquid from the second column volume, stop feeding the material, put the material liquid at normal pressure or compressed air, and then use it Ionized water will press out all the remaining materials. The collected outlet liquid is a low-impurity (A impurity) high-purity acarbose aqueous solution. The high-performance liquid chromatography detects that the pure acarbose is 209.16 grams, of which the A impurity content is 0.48%, and the single-step yield reaches 91.78%.

Embodiment 3

[0022] Example 3: Prepare a pre-purified solution containing 92.35 grams of acarbose, wherein the impurity A content is 1.58%, put the aluminum oxide column on the liquid level, and use air pressure to pass the acarbose pre-purified solution into the alumina column , adjust the size of the outlet valve of the alumina column, control the flow rate of the outlet liquid to 0.4 BV / h, start to collect the outlet liquid from the second column volume, stop feeding the material, put the material liquid at normal pressure or compressed air, and then use it Ionized water will press out all the remaining materials. The collected outlet liquid is a low-impurity (A impurity) high-purity acarbose aqueous solution. The high-performance liquid chromatography detected 83.93 grams of pure acarbose, of which the A impurity content was 0.6%, and the single-step yield reached 90.88 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com