Method for preparing hot-rolled double-phase steel by front super-quick cooling process

A hot-rolled dual-phase steel and ultra-fast cooling technology, which is applied in the field of steel rolling, can solve the problems of not being suitable for the production of dual-phase steel, increasing the difficulty of production, and production costs, so as to avoid transformation, ensure product performance, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Choose steel with the chemical composition in Table 1 as the raw material, numbered 1, 2 and 3, and take two samples a and b for each number to measure its mechanical properties.

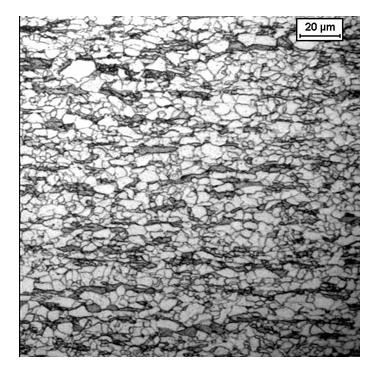

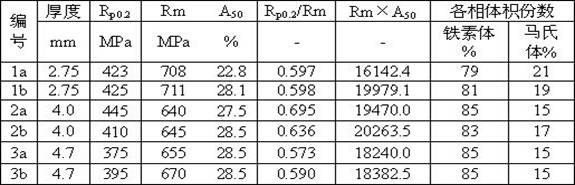

[0021] The size of continuous casting thin slab is (70~90) mm (thickness) × 1300 mm (width) × 9000 mm (length). Rolling, control the starting rolling temperature, finishing rolling temperature and subsequent ultra-fast cooling exit temperature, air cooling time, and coiling temperature, the steel plate thickness specification is 2.75 ~ 4.7mm, the controlled rolling and cooling process is shown in Table 2, and the mechanical properties and the number of parts of the organization are shown in Table 3, and the electron micrograph of the typical metallographic structure of sample 1a is shown in Table 3. figure 1 It can be seen from the figure that its structure is a dual phase of ferrite and martensite.

[0022] Table 1 Chemical composition of duplex steel

[0023] Numbering C Si ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com