Silicon wafer directly-bonded micro-mechanical gyroscope based on silicon through hole technology

A micromachined gyroscope, direct bonding technology, used in steering sensing devices and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0034] See attached figure 1 to attach Figure 6 shown.

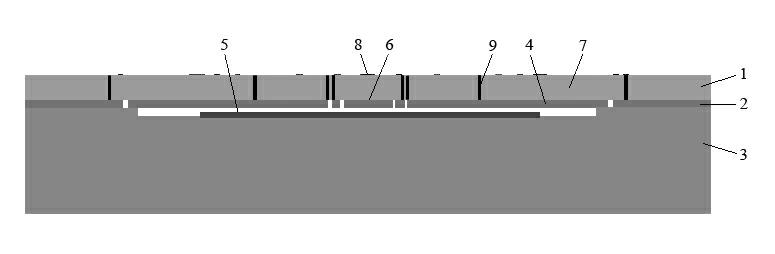

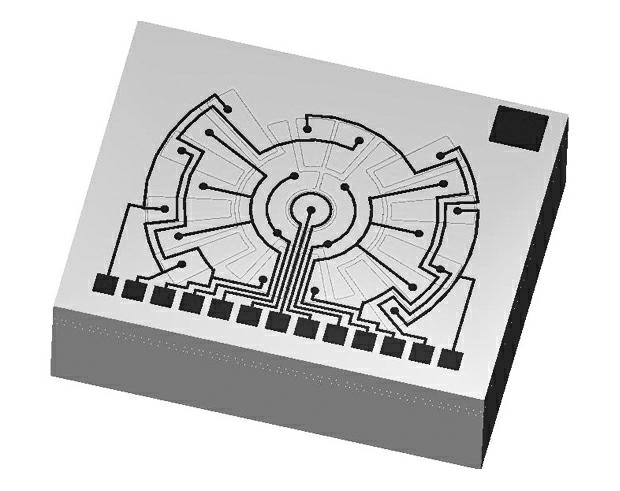

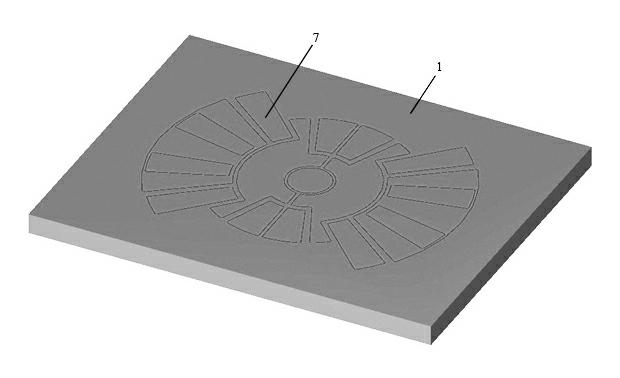

[0035] A micromechanical gyroscope based on the direct bonding of silicon wafers based on through-silicon via technology, which includes three layers of silicon wafer layers directly bonded to silicon-silicon, and the three layers of silicon wafer layers are sequentially fixed electrode wafer layers 1 , the mass block wafer layer 2 , and the capping wafer layer 3 . The materials of the three silicon wafer layers are all highly doped single crystal silicon.

[0036] The fixed electrode wafer layer 1 is a through-hole silicon wafer layer, which has a plurality of through-hole silicon electrodes 7 perpendicular to the through-hole silicon wafer layer, and there are through-hole silicon electrodes 7 perpendicular to the through-hole silicon wafer layer between adjacent through-hole silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com