Transparent liquid crystal display device and manufacturing method thereof

A technology of transparent liquid crystal display and manufacturing method, applied in optics, instruments, nonlinear optics, etc., can solve the problems of poor light absorption capability and poor contrast of transparent display devices, and achieves increasing light absorption characteristics and improving dark state. Dark, contrast-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following examples are given together with the drawings to describe in detail.

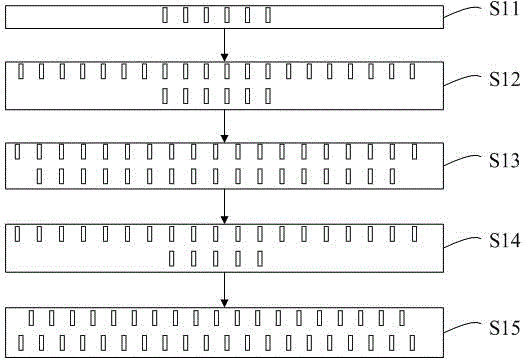

[0043] see figure 1 , which is a flow chart of the steps of the manufacturing method of the transparent liquid crystal display device in an embodiment of the present invention, the manufacturing method includes the following steps.

[0044] In step S11, a pair of substrates is provided. In one embodiment, the pair of substrates are respectively a color filter substrate and a thin film transistor array substrate.

[0045] In step S12, a dichroic dye is added into the liquid crystal material to form a dichroic dye liquid crystal mixture. Herein, the dichroic dye is doped and dissolved in the liquid crystal material, so that the molecular arrangement of the dichroic dye aligns with the axial direction of the liquid crystal material. The liquid crystal material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com