Electron source package

An electron source and power supply technology, applied in the manufacture of circuits, electrical components, electrode systems, etc., can solve the problems of large transport resistance, large degree of surface damage, and reduced collection efficiency of nanowire array photocathode, so as to improve the absorption rate , reduce the probability of emission, and enhance the effect of quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

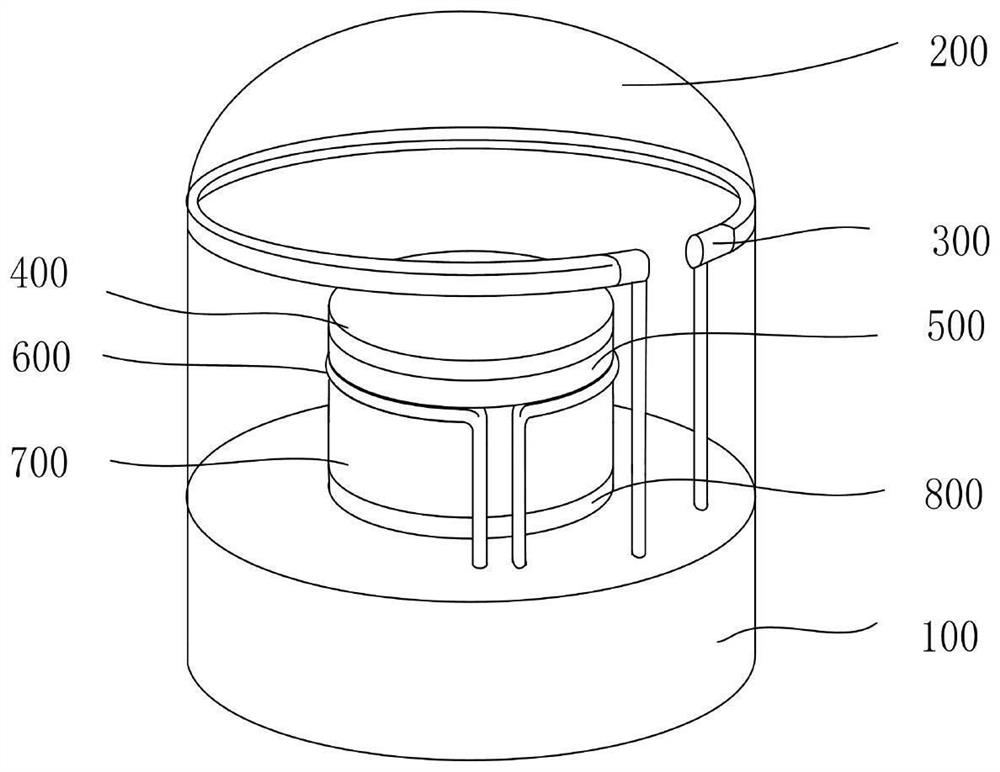

[0018] combine Figure 1-Figure 3 , which is the first embodiment of the present invention, provides an electron source package for photoemission by external photoelectric effect, including a substrate 100, a sealing cover 200, and an electron source. The substrate 100 is used to carry the electron source, the sealing cover 200 cooperates with the substrate 100 to form a closed space, and the electron source emits electrons under the external photoelectric effect. Specifically, the substrate 100 includes a substrate housing and a power circuit disposed in the substrate housing. The substrate housing not only protects the power circuit, but also supports the electron source. The sealing cover 200 is a transparent cover to seal and form a vacuum environment, and the transparent material is convenient for subsequent devices to collect overflowing electrons.

[0019] Further, the power supply circuit includes a bias voltage circuit.

[0020] Further, the electron source includes...

Embodiment 2

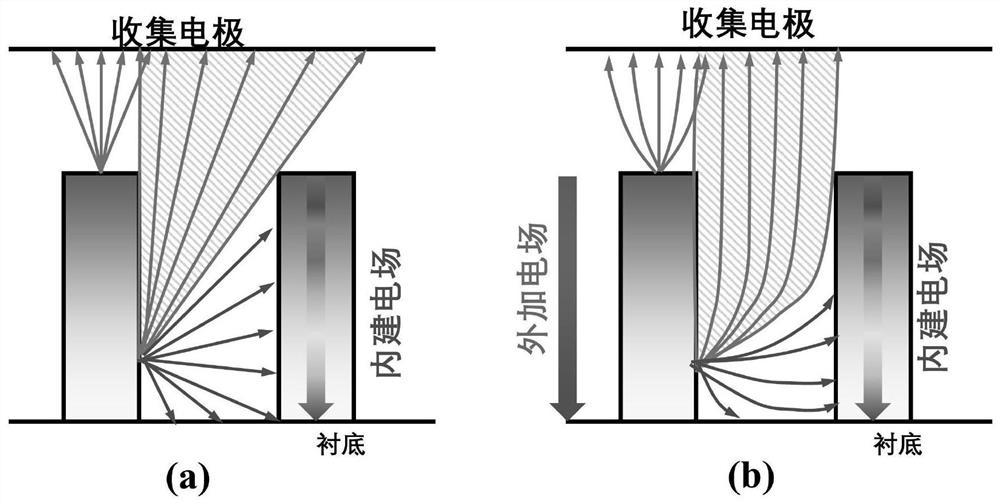

[0025] combine Figure 4 , 5 , is the second embodiment of the present invention. The difference between this embodiment and the first embodiment is that a nanowire structure and growth environment are provided. In this embodiment, the nanowire 700 is grown on the substrate 800 . The surface of the substrate 800 includes several raised structures 820 , and each nanowire 700 in the nanowire bundle grows on the corresponding raised structures 820 . Nanowires can be grown on the raised structure 820, which can make the nanowires grow in an orderly and fixed position, and the grown array has a fixed period and adjustable diameter; at the same time, the method of growing nanowires on the raised structure The formation of dense arrays can be avoided, and the electrons emitted from the side have more possibilities to move to the top collecting electrode, reducing the probability of being repeatedly absorbed by adjacent nanowires.

[0026] Further, each nanowire 700 of the nanowire...

Embodiment 3

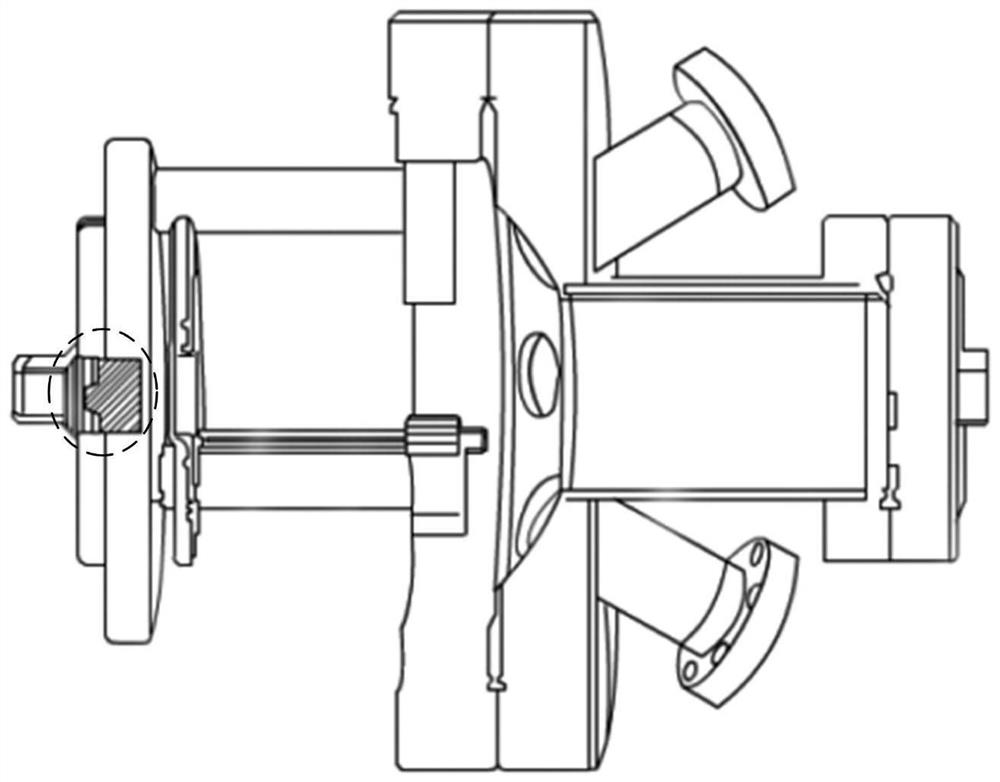

[0031] combine Figure 6 , which is the third embodiment of the present invention, provides a method for making the nanowires involved in the second embodiment, including producing neatly arranged nano-scale SiO on the surface of the substrate 2 Masking method, growing heterojunction Al x Ga 1-x Method of N nanowire array and fabrication into heterojunction Al x Ga 1-x The invention discloses a preparation method of an N / GaN nanowire array electron source cathode.

[0032] Step S100, producing neatly arranged nano-scale SiO on the surface of the substrate 2 Mask method:

[0033] Step S101, cleaning the sapphire Al with acetone, alcohol and deionized water with a volume ratio of 1:1:2 2 o 3 substrate, on sapphire Al 2 o 3 On the (0001) surface, a layer of GaN thin film is grown by MOCVD method, and the layer thickness is 1.5mm;

[0034] Step S102, depositing a layer of SiO on the GaN film by radio frequency sputtering 2 , with a thickness of 40nm; through electron be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com