Side-by-side cable

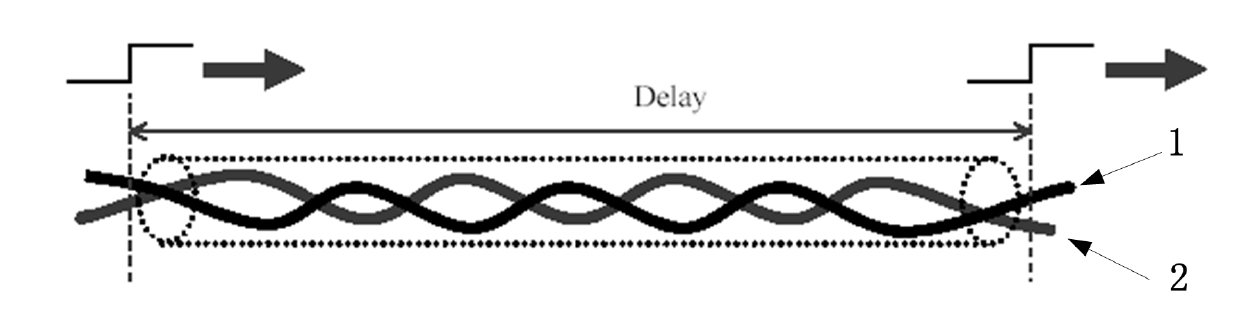

A cable and cable technology, applied in the field of side-by-side cables, can solve the problems of low stability of twisted pair electrical characteristics, low customer processing efficiency, unfavorable automatic production lines, etc., to achieve automatic production lines, excellent sealing and electrical properties. Insulation, the effect of saving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the side-by-side cable provided by the present invention will be described in detail below with reference to the accompanying drawings.

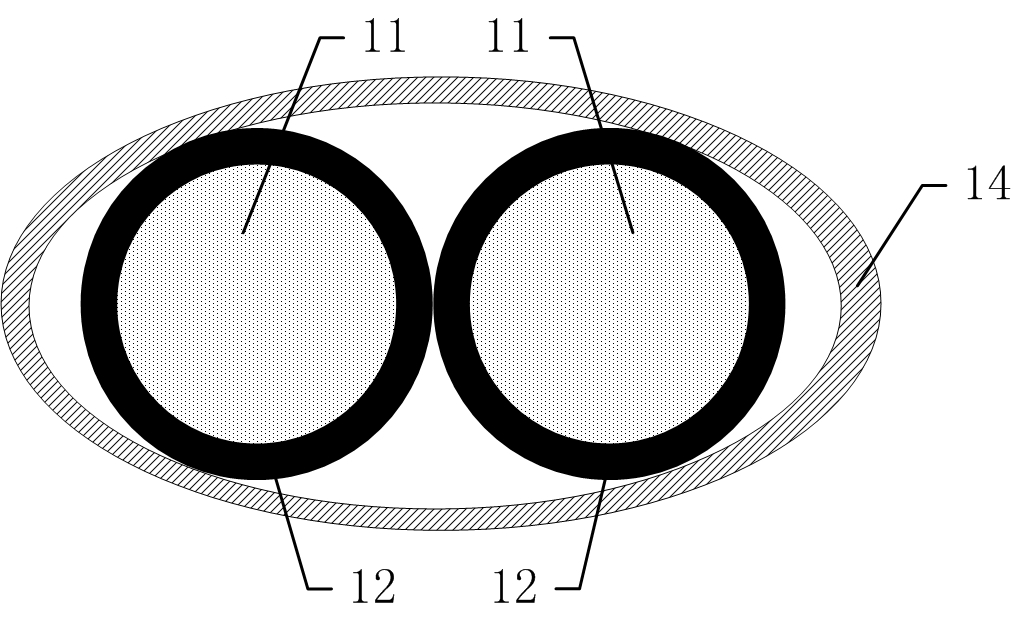

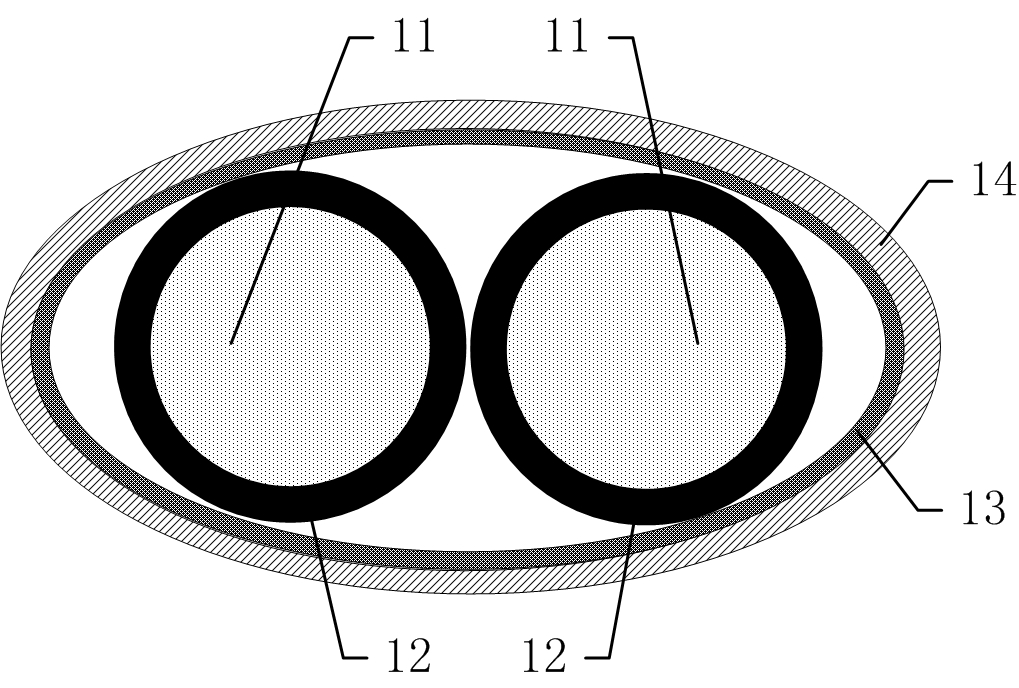

[0018] Reference attached figure 2 As shown, a schematic diagram of an embodiment of the side-by-side cable of the present invention, including at least two conductors 11, an insulating layer 12 covering each of the conductors 11, the conductors 11 and the insulating layer 12 constitute a Teflon wire, After the two Teflon wires are arranged side by side, a cladding layer is coated on the outside, and the polyester tape 14 is used to cover the outer layer of the two Teflon wires side by side.

[0019] All conductors 11 are placed side by side and are electrical conductors used to transmit signals or transmit electricity, which can be metal, fiberglass, metal-coated substrates or combinations thereof, such as solid copper, stranded copper wire, tinned copper wire , aluminum, alloy or their combination, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com