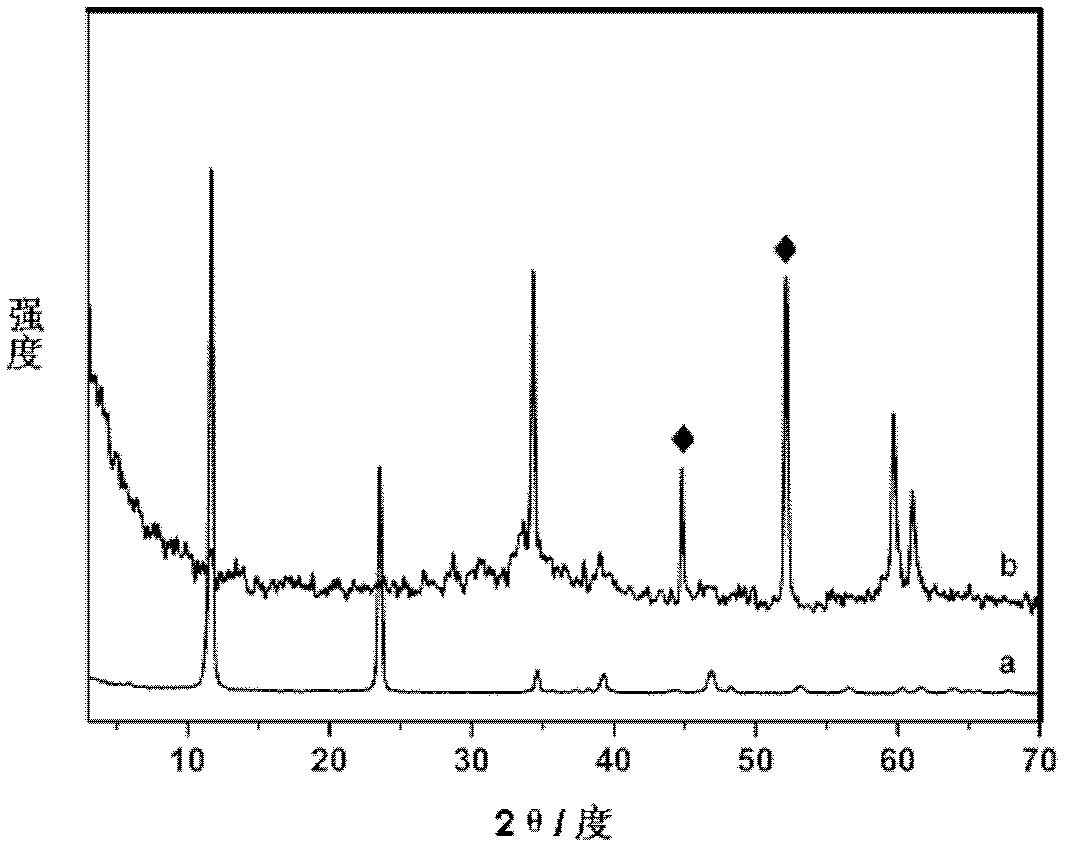

Preparation method of ultracapacitor material with layered double hydroxide-poly(3, 4-ethylenedioxythiophene) core-shell structure

A technology of ethylenedioxythiophene and core-shell structure, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of easy agglomeration of active substances, high price, poor conductivity of active components, etc., to inhibit aggregation and ensure effective transfer. , Improve the effect of poor magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

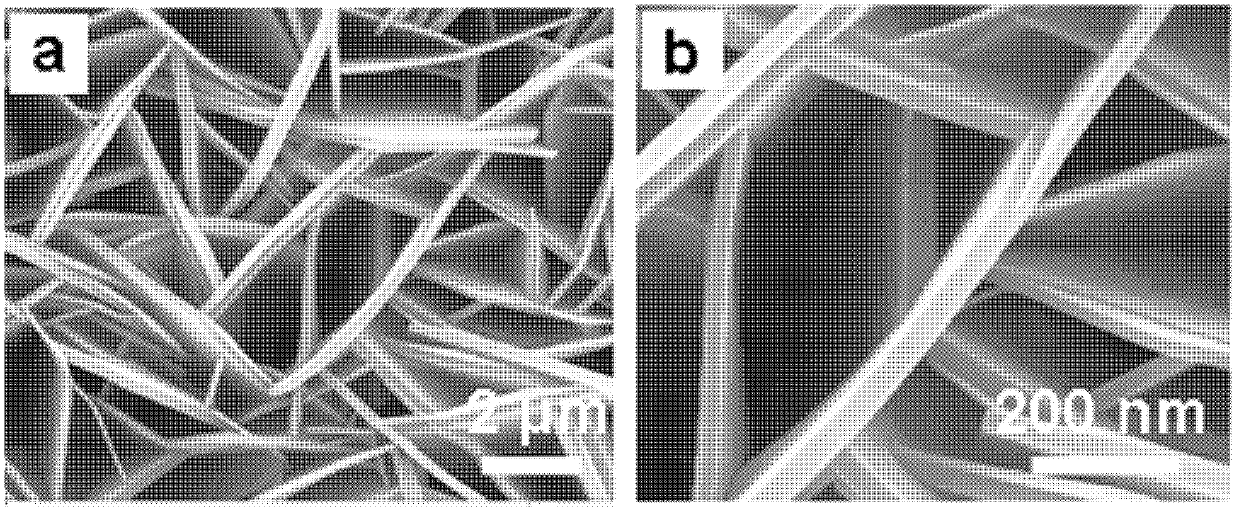

Embodiment 1

[0024] Step A: Weigh 0.218g Co(NO 3 ) 2 ·6H 2 O and 0.094g Al(NO 3 ) 3 9H 2 O(Co / Al=3) dissolved in 50ml to remove CO 2 Prepare mixed salt solution with deionized water;

[0025] Step B: Weigh 0.15g urea and 0.042g ammonium fluoride and dissolve them in 50ml to remove CO 2 Deionized water is made into solution A with a concentration of 0.05mol / L and solution B with a concentration of 0.02mol / L;

[0026] Step C: Take 20ml of the transparent and clear solution obtained in step a, 10ml of solution A and 10ml of solution B obtained in step b, mix the three in an autoclave, and put it into ITO glass, then seal the autoclave and put it in 110 In the oven at ℃, take it out after 10 hours of reaction, wash off the surface residue with deionized water, and obtain a hydrotalcite array film on the ITO glass;

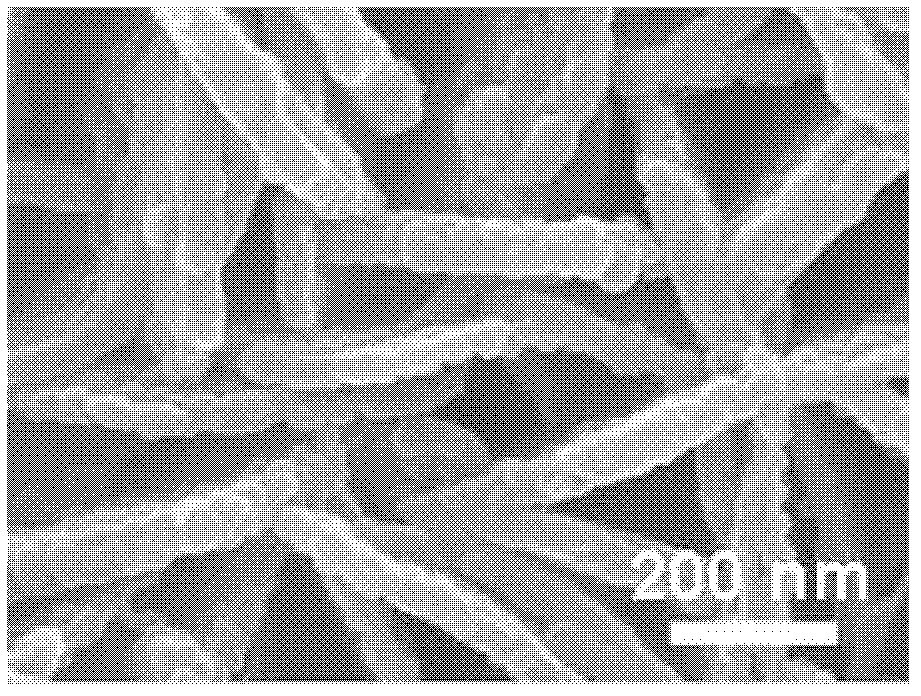

[0027]Step D: take the ITO glass with a hydrotalcite array thin film on the surface obtained in step c, and coat the surface with a layer of poly(3,4-ethylenedioxythiophene...

Embodiment 2

[0036] Step A: Weigh 0.145g Co(NO 3 ) 2 ·6H 2 O and 0.094g Al(NO 3 ) 3 9H 2 O(Co / Al=2) dissolved in 50ml to remove CO 2 Prepare mixed salt solution with deionized water;

[0037] Step B: Weigh 0.12g urea and 0.032g ammonium fluoride and dissolve them in 50ml to remove CO 2 A solution with a concentration of 0.04mol / L and a B solution with a concentration of 0.015mol / L were prepared in deionized water;

[0038] Step C: Take 12ml of the transparent and clear solution obtained in step a, 8ml of solution A and 8ml of solution B obtained in step b, mix the three in the autoclave, and put cobalt chips into it, then seal the autoclave and put it in 120 ℃ oven, take it out after 15 hours of reaction, wash off the surface residue with deionized water, and obtain a hydrotalcite array film on the ITO glass;

[0039] Step D: take the ITO glass with a hydrotalcite array thin film on the surface obtained in step c, and coat the surface with a layer of poly(3,4-ethylenedioxythiophene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com