Yogurt containing fish oil

A technology of yogurt and fish oil, applied in milk preparations, dairy products, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

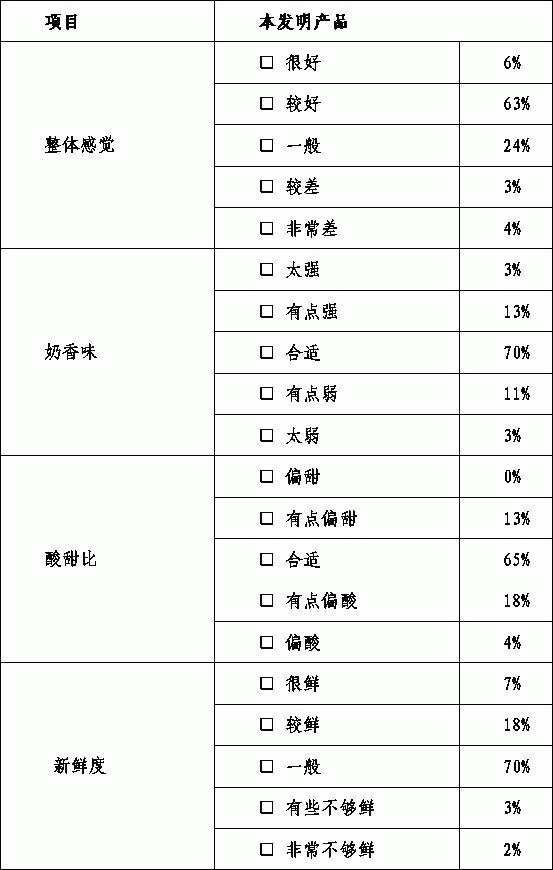

Image

Examples

Embodiment 1

[0072] (1) Mix the stabilizer composed of 0.1kg of carrageenan, 0.1kg of microcrystalline cellulose, and 2.8 modified starch with 5 times the weight of white sugar (15Kg), then add white sugar (35Kg), 3Kg of whey protein wpc80, fish oil 0.1Kg, vitamin C palmitate 0.01 Kg, vitamin E 0.001 Kg, lecithin 0.1Kg; dissolve with 300Kg, 70℃ low-fat milk liquid, and stir for 10min;

[0073] (2) Mix and quantify the remaining 400kg of low-fat milk. Cool to below 10°C.

[0074] (3) Homogenize the material at 18Mpa / 65°C and sterilize at 95°C / 300s;

[0075] (4) Cool the material to 42°C and insert 200u of bacteria. Mix for 10 min. The strain is a 3:3:1:1 combination of Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus acidophilus, and Bifidobacterium.

[0076] (5) Ferment at 42°C, and the acidity at the end is controlled at 70 O T.

[0077] (6) Turn over the cylinder and cool it down. After the acidity reaches the requirement, turn on the ice water, start the agitat...

Embodiment 2

[0080] (1) Mix the stabilizer composed of 2.5kg of carrageenan, 2.5kg of microcrystalline cellulose, and 5kg of modified starch with 90kg of white sugar, then add 15Kg of whey protein wpc80, 5Kg of deep-sea fish oil, 1Kg of vitamin C palmitate, vitamin E 0.05 Kg, lecithin 0.5 Kg, dissolved in 700Kg, 75°C low-fat non-antibiotic fresh milk, and stirred for 12 minutes;

[0081] (2) Mix and quantify the remaining 200kg of low-fat antibiotic-free fresh milk. Cool to 8°C.

[0082] (3) Homogenize the material at 20Mpa / 70°C and sterilize at 100°C / 300s;

[0083] (4) Cool the material to 45°C, and insert 250u of bacteria. Mix for 10 min. The strain is a 3:3:2:1 combination of Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus acidophilus, and Bifidobacterium.

[0084] (5) Ferment at 45°C, and the acidity at the end is controlled at 80 O T.

[0085] (6) Turn over the cylinder and cool it down. After the acidity reaches the requirement, turn on the ice water, start...

Embodiment 3

[0088] (1) Mix the stabilizer composed of 0.5kg of carrageenan, 0.2kg of microcrystalline cellulose, and 4.3kg of modified starch with 5 times the weight of white sugar (25Kg), then add the remaining sugar (55Kg) and 9Kg of concentrated whey protein, Fish oil 2.6Kg, vitamin C palmitate 0.5 Kg, vitamin E 0.025 Kg, lecithin 0.35 Kg were dissolved in 450Kg low-fat milk at 75°C and stirred for 20 minutes;

[0089] (2) Mix and quantify the remaining 400kg of low-fat milk. Cool to 12°C.

[0090] (3) Homogenize the material at 20Mpa / 67°C and sterilize at 95°C / 300s;

[0091] (4) Cool the material to 44°C, and put in 220u of the strain and 0.1kg of orange essence. Mix for 10 min. The strain is composed of Streptococcus thermophilus, Lactobacillus bulgaricus, and Lactobacillus acidophilus at a ratio of 1:1:2.

[0092] (5) Ferment at 44°C, and the acidity at the end is controlled at 75 O T.

[0093] (6) Turn over the cylinder and cool it down. After the acidity reaches the require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com