Ecological wetland buffering system along high-speed rails

An ecological wetland and buffer system technology, applied in the direction of sustainable biological treatment, noise absorption device, biological water/sewage treatment, etc., can solve the problems of secondary pollution, less ecological technology, etc., achieve stable water output, flexible device combination, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

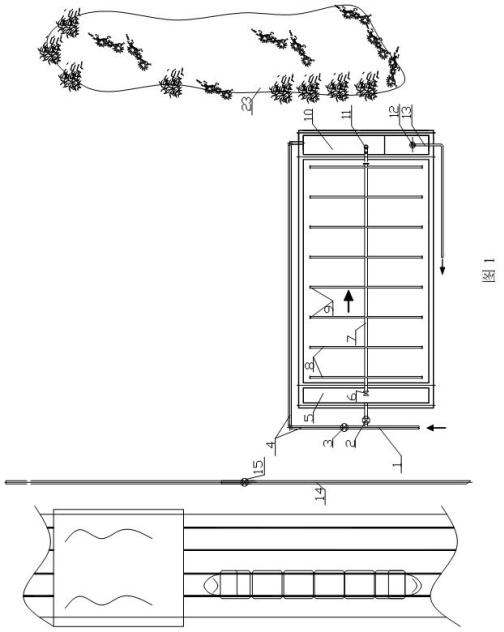

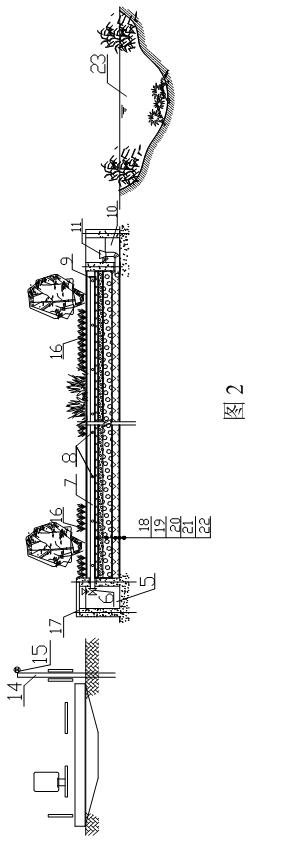

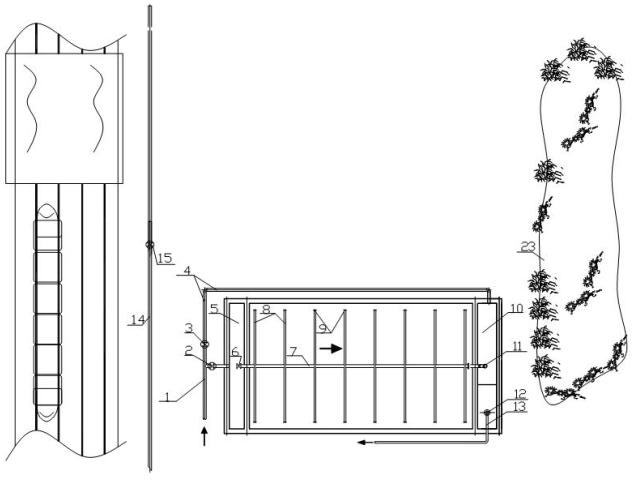

[0024] Such as figure 1 , figure 2 As shown, the ecological wetland buffer system used along the high-speed rail includes a constructed wetland system and sound-absorbing and noise-reducing components. The constructed wetland system is built on isolated land along the high-speed rail. The water inlet channel 5 and the water outlet channel 10, and the isolated land along the high-speed rail line are laid with a plain soil compaction layer 22, and a waterproof layer 21 is laid on the plain soil compaction layer 22, and a drainage groove 20 is laid on the waterproof layer 21, and the height of the drainage groove 20 is 10-20mm. The ecological filler layer 19 and the mixed filler layer 18 are successively laid on the drainage tank 20, the thickness of the mixed filler layer 18 is 100-200mm, the thickness of the ecological filler layer 19 is 100mm-350mm, and the water distribution main pipe 7 and the water distribution main pipe 7 are erected on the mixed filler layer 18. Branch ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com