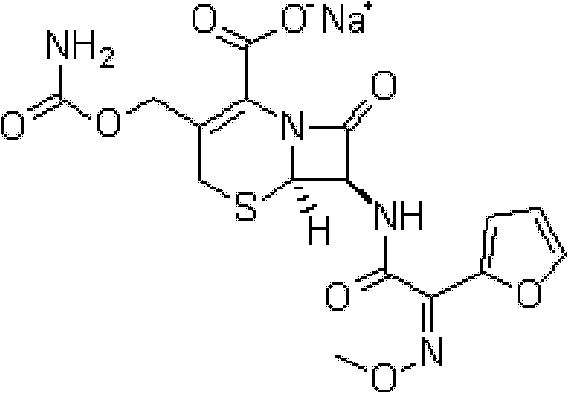

Method utilizing coupling reaction crystallization to prepare cefuroxime sodium

A technology of cefuroxime sodium and coupling reaction, applied in the direction of organic chemistry, can solve the problems of increasing solvent recovery difficulties, insoluble particles, complicated operation, etc., and achieve the effect of reducing adsorption and filtration process, reducing degradation, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 70ml of acetone and 10ml of pure water into the crystallizer, put in 7g of cefuroxime acid, and stir at 20°C until fully dissolved. 4.4ml of sodium carbonate aqueous solution with a concentration of 0.2g / ml was added dropwise to the cefuroxime acid solution and stirred at constant temperature for 10min to complete the reaction. Add 0.28 g of cefuroxime sodium seed crystal, keep the temperature for 10 minutes, and add 480 ml of acetone dropwise. Then the temperature is lowered to 5°C and kept at a constant temperature for 0.5h. Filtration with suction, washing with acetone, and drying at 20°C and a vacuum degree of 0.08 MPa for 3 hours to obtain cefuroxime sodium product. The color grade of the product is lower than Y1 or YG1, the purity is 99.6%, and the yield is 95.3%.

Embodiment 2

[0021] Add 145ml of acetone and 95ml of ethanol to the crystallizer, add 10g of cefuroxime acid, control the temperature at 25°C and stir until it is completely dissolved. A mixture of 2.2 ml of sodium carbonate aqueous solution with a concentration of 0.3 g / ml and 6.7 ml of sodium isooctanoate aqueous solution was added dropwise to the cefuroxime acid solution and stirred at constant temperature for 15 minutes to complete the reaction. Add 0.5 g of cefuroxime sodium seed crystals, add 950 ml of ethanol dropwise after 20 minutes of constant temperature. Then, the temperature was lowered to 0°C and kept constant for 1h. Suction filtration, ethanol washing, 20°C, vacuum degree of 0.1MPa and drying for 2 hours to obtain cefuroxime sodium product. The color grade of the product is lower than Y1 or YG1, the purity is 99.5%, and the yield is 93.7%.

Embodiment 3

[0023] Add 70ml of acetone and 20ml of pure water into the crystallizer, add 9g of cefuroxime acid, and stir at 30°C until fully dissolved. Add 8.9 ml of sodium isooctanoate aqueous solution with a concentration of 0.4 g / ml to the cefuroxime acid solution, and stir at constant temperature for 20 minutes to complete the reaction. Add 0.54 g of cefuroxime sodium seed crystals, keep the temperature constant for 15 minutes, and then add 450 ml of acetone dropwise. Then, the temperature was lowered to 2°C and kept constant for 1.5h. Suction filtration, acetone washing, 30°C, vacuum degree 0.09MPa and drying for 1.8 hours to obtain cefuroxime sodium product. The color grade of the product is lower than Y2 or YG2, the purity is 99.5%, and the yield is 92.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com