Polyester industrial yarn solid-phase polymerization flame-retarding chain extender and preparing method thereof

A technology of polyester industrial yarn and solid-state polymerization, which is applied in the direction of chemical instruments and methods, single-component copolyester rayon, compounds of Group 5/15 elements of the periodic table, etc., can solve the difficulty of removing small molecules, Strict equipment requirements, high cost, etc., to achieve the effect of avoiding cumbersome process, mild reaction conditions, and improving intrinsic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

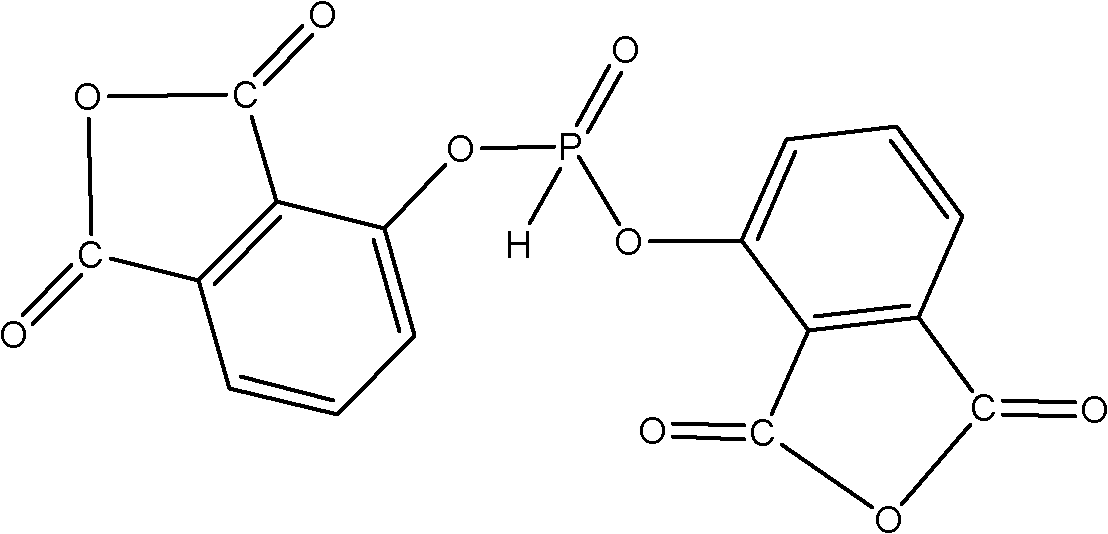

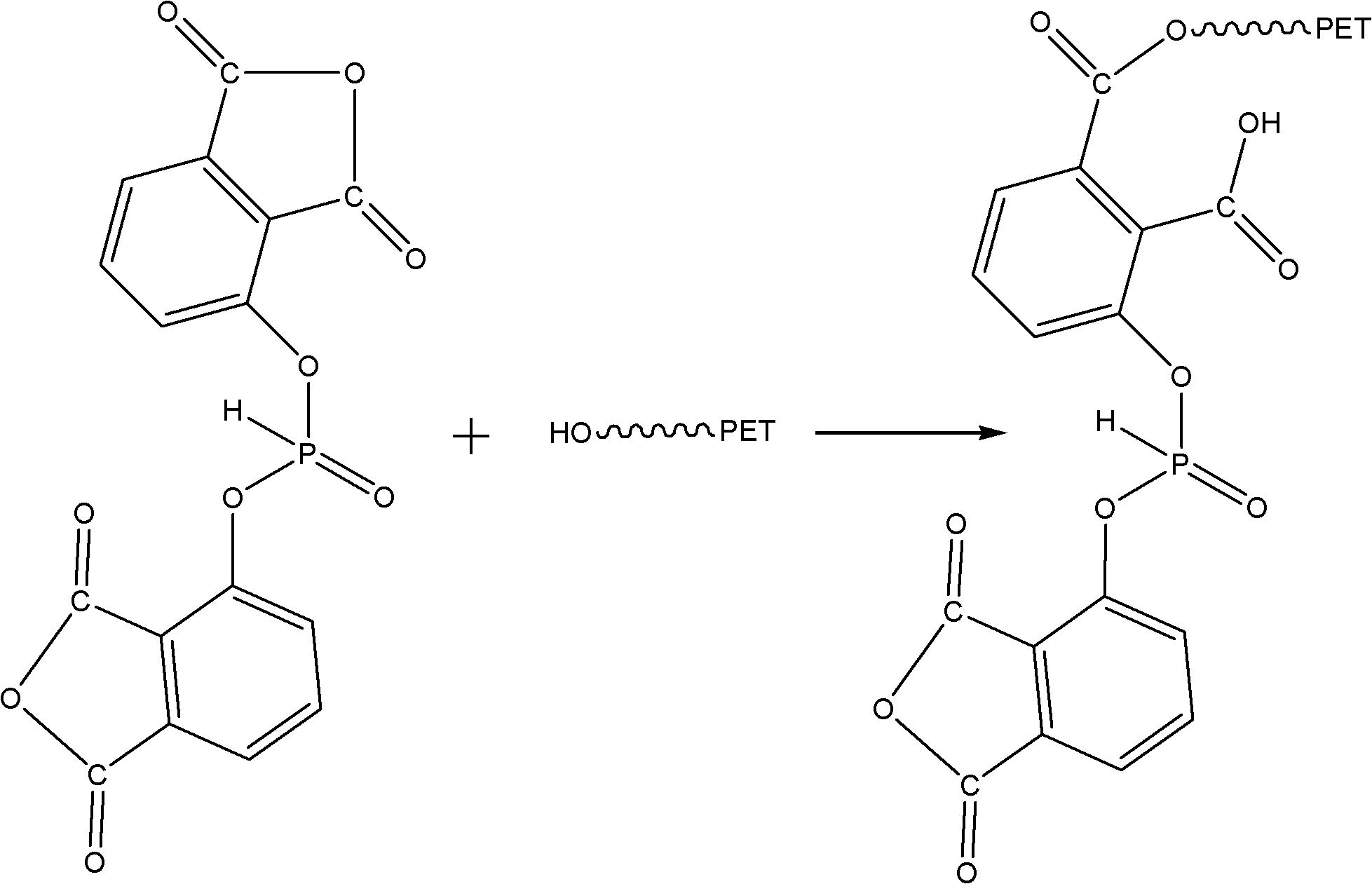

Method used

Image

Examples

Embodiment 1

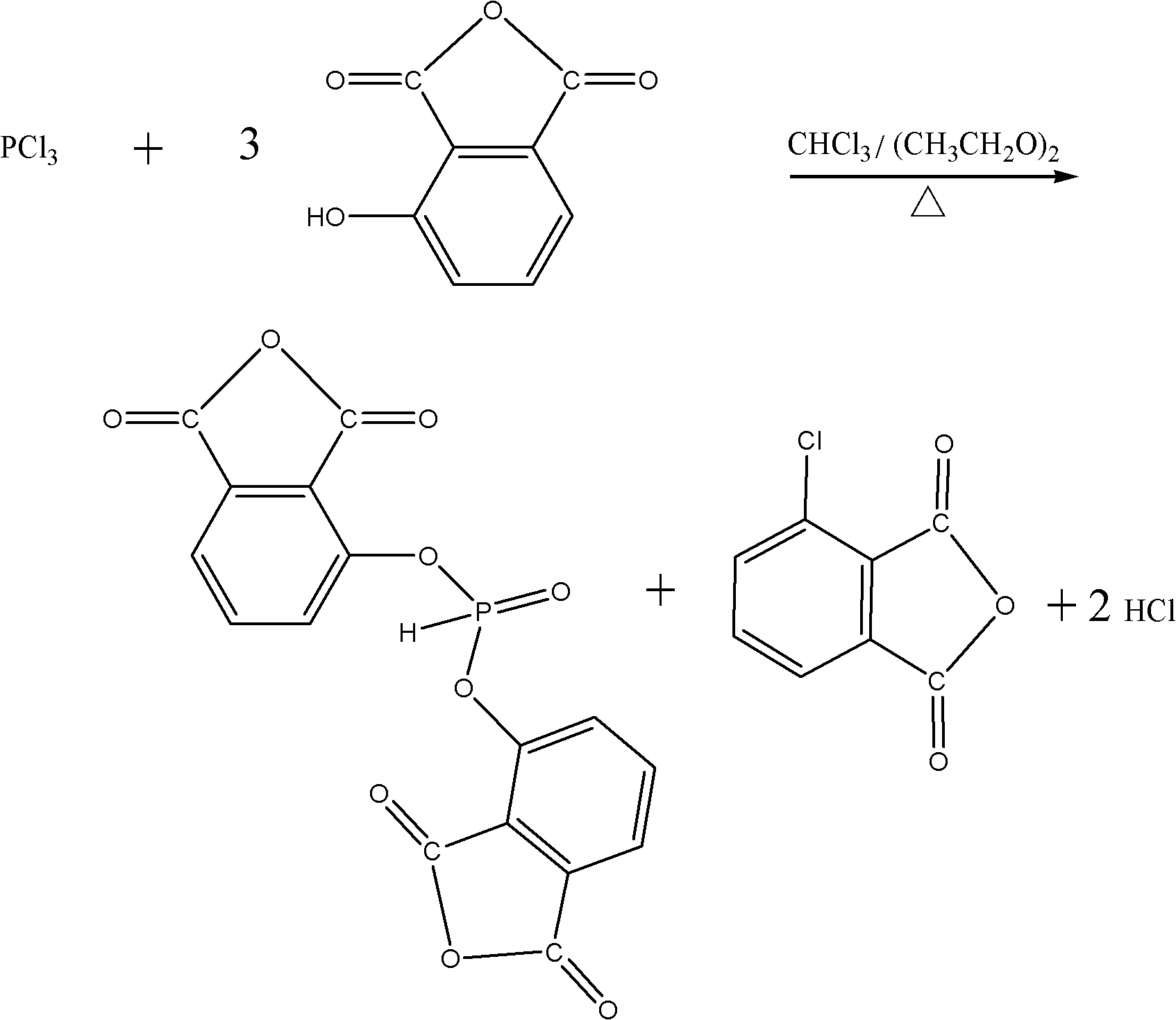

[0024] (1) CHCl 3 with (CH 3 CH 2 O) 2 The mixed solution is used as a solvent, and the solute is respectively prepared as PCl 3 The A solution and the B solution whose solute is 3-hydroxyphthalic anhydride; wherein, CHCl 3 with (CH 3 CH 2 O) 2 The volume ratio is 5:1, PCl in solution A 3 The molar volume concentration of is 0.3mol / L, and the molar volume concentration of 3-hydroxyphthalic anhydride in B solution is 0.05mol / L;

[0025] (2) Slowly add the B solution to the A solution system under the condition of 80°C and keep stirring. After the dropwise addition of the B solution, reflux at 80°C for 2 hours, and then evaporate at 60°C. is 30vol%, and then filtered to obtain the required flame retardant chain extender crude product; wherein, the volume ratio of A solution and B solution is 1: 3.5;

[0026] (3) The obtained flame retardant chain extender crude product is 5:1 CHCl with a volume ratio 3 with (CH 3 CH 2 O) 2 The mixed solution is used as a solvent, an...

Embodiment 2

[0028] (1) CHCl 3 with (CH 3 CH 2 O) 2 The mixed solution is used as a solvent, and the solute is respectively prepared as PCl 3 The A solution and the B solution whose solute is 3-hydroxyphthalic anhydride; wherein, CHCl 3 with (CH 3 CH 2 O) 2 The volume ratio is 8:1, PCl in solution A 3The molar volume concentration of is 0.2mol / L, and the molar volume concentration of 3-hydroxyphthalic anhydride in B solution is 0.05mol / L;

[0029] (2) Slowly add solution B to solution A at 60°C and stir continuously. After adding solution B dropwise, reflux at 60°C for 2 hours, and then evaporate at 60°C. is 30vol%, and then filtered to obtain the required flame retardant chain extender crude product; wherein, the volume ratio of A solution and B solution is 1: 3.5;

[0030] (3) The obtained flame retardant chain extender crude product is 5:1 CHCl with a volume ratio 3 with (CH 3 CH 2 O) 2 The mixed liquid is used as a solvent, and the desired flame-retardant chain extender cr...

Embodiment 3

[0032] (1) CHCl 3 with (CH 3 CH 2 O) 2 The mixed solution is used as a solvent, and the solute is respectively prepared as PCl 3 The A solution and the B solution whose solute is 3-hydroxyphthalic anhydride; wherein, CHCl 3 with (CH 3 CH 2 O) 2 The volume ratio is 8:1, PCl in solution A 3 The molar volume concentration of is 0.3mol / L, and the molar volume concentration of 3-hydroxyphthalic anhydride in B solution is 0.2mol / L;

[0033] (2) Slowly add solution B to solution A at 80°C and keep stirring. After adding solution B dropwise, reflux reaction at 80°C for 3 hours, and then evaporate at 60°C. 30vol%, and then filtered to obtain the required flame retardant chain extender crude product; wherein, the volume ratio of A solution and B solution is 1: 3.4;

[0034] (3) the obtained flame retardant type chain extender crude product is 8:1 CHCl with a volume ratio 3 with (CH 3 CH 2 O) 2 The mixed liquid is used as a solvent, and the required flame-retardant chain ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com