Composition of color high-concentration mono-color master batch for polyolefin

A composition and high-concentration technology, applied in the coloring of films or injection molded parts, in the field of single-color masterbatch compositions for colored high-concentration polyolefins, which can solve the problems of insufficient market share of color masterbatches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

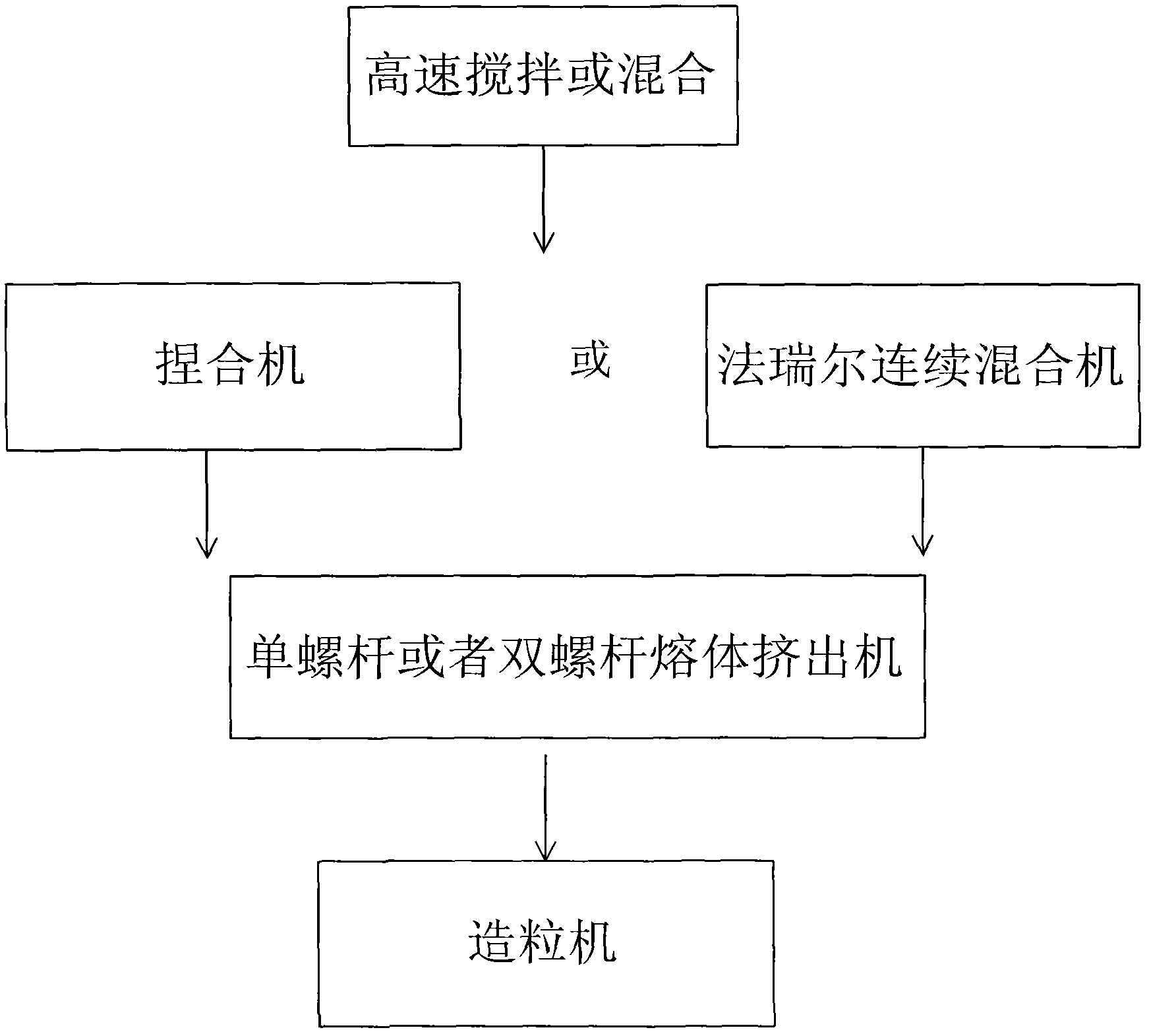

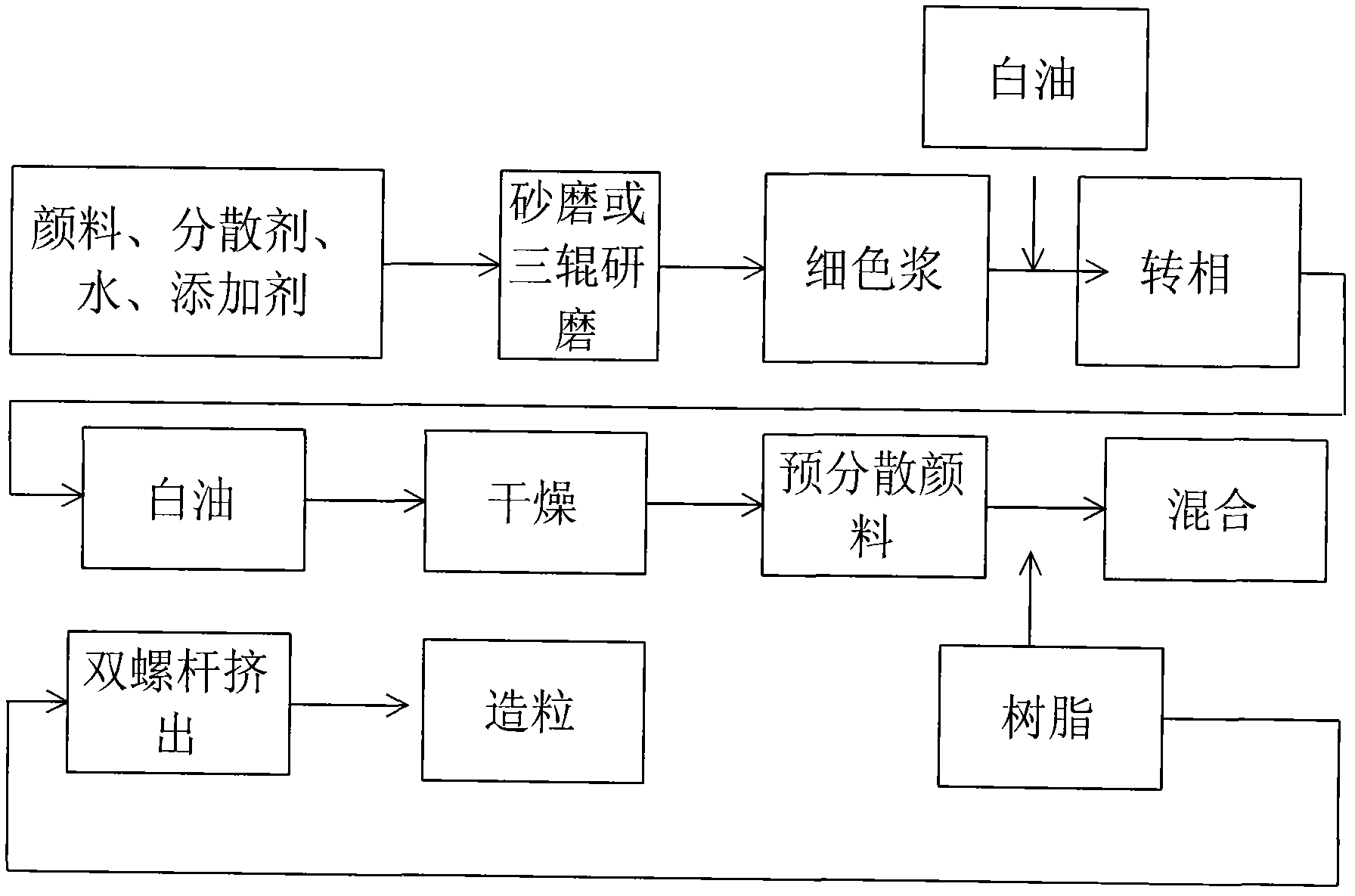

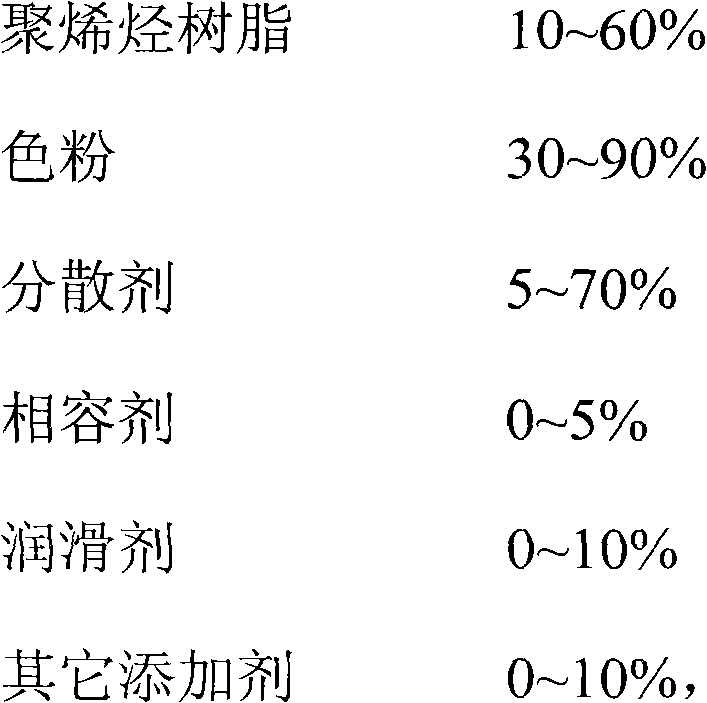

Method used

Image

Examples

Embodiment 1

[0070] Pigment Red53:1: 55%

[0071] LLDPE: 20% (MI is 50g / 10min)

[0072] m-PE: 10% (MI is 30g / 10min)

[0073] Micronized Wax: 5%

[0074] Low molecular weight polyethylene wax dispersant: 9.5%

Embodiment 2

[0077] Pigment Red 48:2: 60%

[0078] LLDPE: 16% (MI is 50g / 10min)

[0079] APAO: 8% (MI is 70g / 10min)

[0080] m-PE: 5% (MI is 20g / 10min)

[0081] m-PE wax dispersant: 10%

Embodiment 3

[0084] Pigment Yellow 83: 60%

[0085] LLDPE: 10% (MI is 50g / 10min)

[0086] m-PE: 10% (MI is 25g / 10min)

[0087] m-PP wax dispersant: 10%

[0088] Polyethylene-vinyl acetate dispersant: 6%

[0089] Erucamide: 3%

[0090] Antioxidant 1010: 0.3%

[0091] Antioxidant 168: 0.7%

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com