Emulsion paint containing attapulgite and preparation method for emulsion paint containing attapulgite

A technology of attapulgite and latex paint, applied in latex paint, coating, etc., can solve the problem of no thickener, etc., achieve the effects of preventing pigment sedimentation, obvious thixotropic thickening effect, and improving syneresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: A kind of latex paint containing attapulgite, the parts by weight of its raw materials are: 217.5 parts of water, 2 parts of cellulose, 5 parts of dispersant SN-5040, 1 part of antifungal agent, auxiliary agent AMP-95: 1.5 parts, alcohol ester-12: 18 parts, PE-100: 1 part, defoamer JR-321: 1.5 parts, propylene glycol: 18 parts, heavy calcium 1000 mesh: 86 parts, talcum powder: 55 parts , Titanium dioxide: 180 parts, attapulgite: 4 parts, additive BYK022: 1.5 parts, emulsion SD-818: 400 parts, thickener RM2020: 5 parts, thickener AR-235: 3 parts.

[0016] The preparation method of latex paint containing attapulgite comprises the following steps: placing a disperser under a high-speed dispersing device, feeding materials in sequence according to the serial numbers of the raw materials, first putting components 1-9 into a dispersing container in sequence, and placing the disperser Disperse at high speed at 700 rpm for 5 minutes; then increase the speed to 300...

Embodiment 2

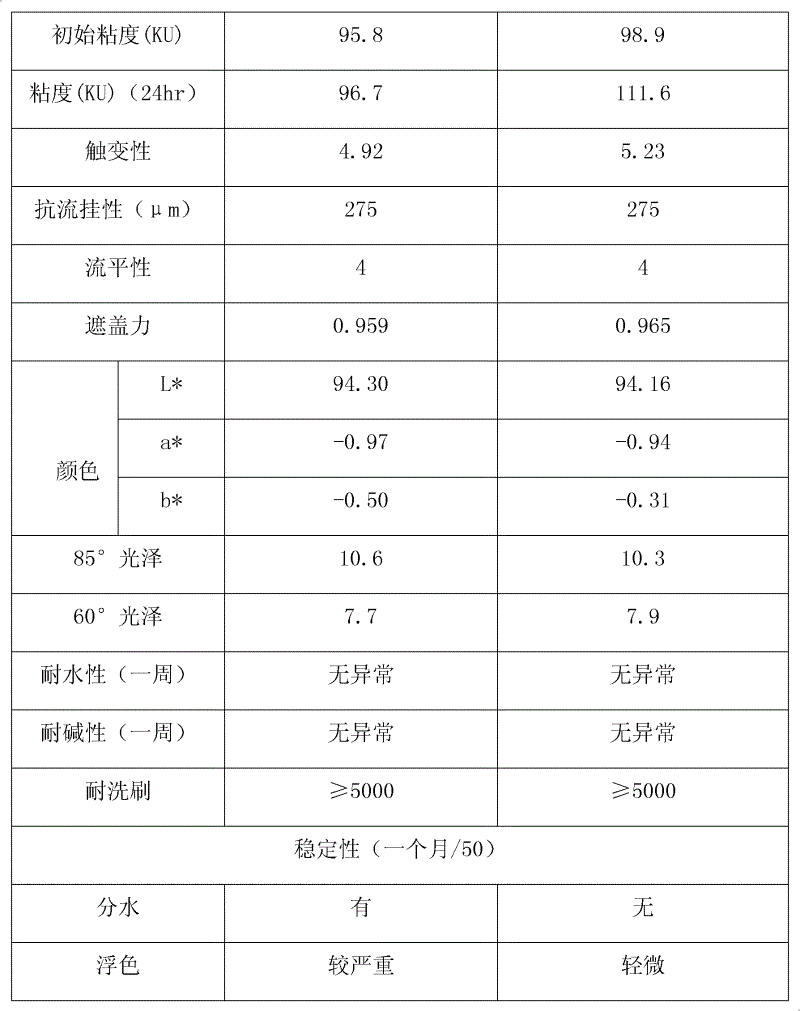

[0018] Embodiment 2: A kind of effect comparison of using attapulgite as a thickener to prepare latex paint and not adding attapulgite comparative examples:

[0019] A kind of embodiment that prepares latex paint with attapulgite as thickener is shown in Example 1;

[0020] Comparative example without attapulgite: in parts by weight: water: 217.5 parts, cellulose: 2 parts, dispersant SN-5040: 5 parts, antifungal agent: 1 part, auxiliary agent AMP-95: 1.5 parts, Alcohol ester-12: 18 parts, PE-100: 1 part, defoamer JR-321: 1.5 parts, propylene glycol: 18 parts, heavy calcium 1000 mesh: 90 parts, talcum powder: 55 parts, titanium dioxide: 180 parts, Additive BYK022: 1.5 parts, emulsion SD-818: 400 parts, thickener RM2020: 5 parts, thickener AR-235: 3 parts, total 1000 parts

[0021] The operation process of this embodiment: place the disperser under the high-speed dispersing equipment, feed materials in sequence according to the serial number, first put the components 1-9 into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com