High-temperature resistant and strong corrosive resistant water-based baking varnish for metal and preparation method for baking varnish

A high-temperature-resistant, metal-based technology, which is applied in the field of high-temperature-resistant and strong-corrosion-resistant water-based baking varnishes for metals and its preparation, can solve problems such as waste of energy, poor high-temperature resistance of water-based baking varnishes, and environmental pollution, and achieve excellent physical and mechanical properties. Good adhesion and short construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

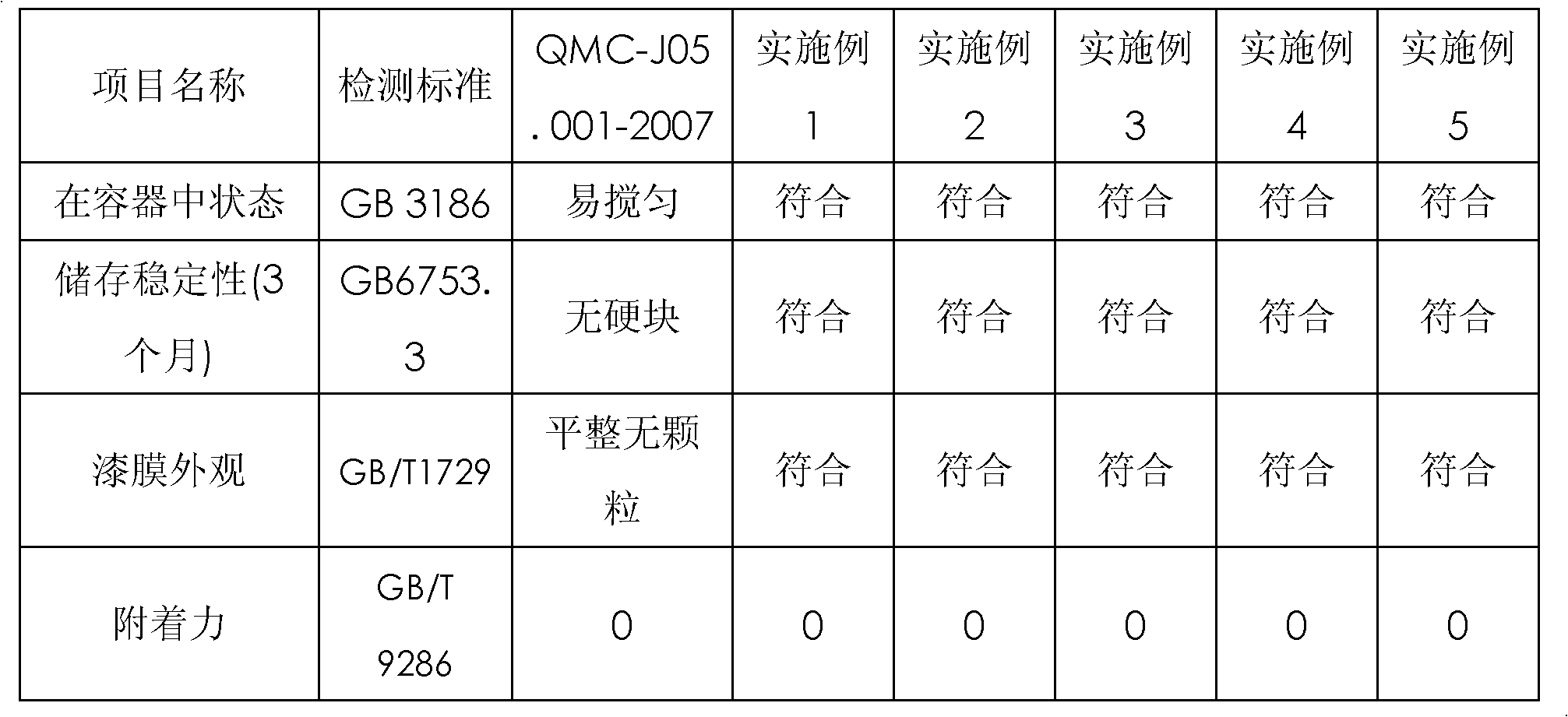

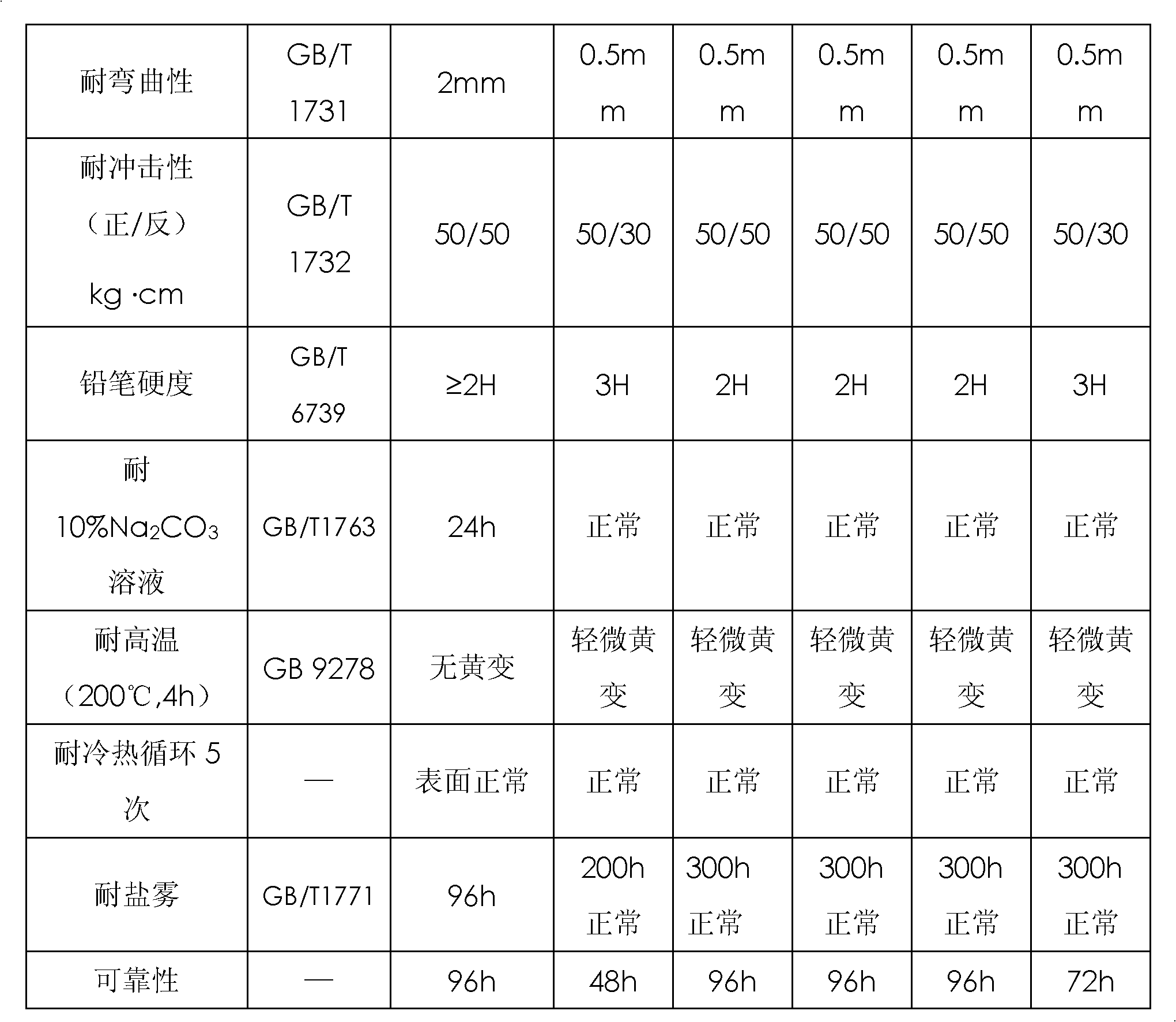

Examples

Embodiment 1

[0044] Under the rotating speed of 400r / min, in terms of mass parts, add 26 parts of tap water, 25 parts of modified water-soluble acrylic resin (RB-306, Rongbiao paint, Shunde District, Foshan City), 3 parts of cosolvent (ethylene glycol Butyl ether, Dow Chemical), 0.2 parts of wetting and dispersing agent (Orotan 731A, Rohm and Haas, USA) and 0.3 parts of wetting and dispersing agent (Hydropalat 3275, Shenzhen Haichuan Chemical Co., Ltd.), 0.2 parts of pH regulator (AMP95, Dow Chemical), 0.05 parts of defoamer (Foamex902W, TEGO company), after stirring for 5min, the rotating speed is adjusted to 1000r / min, and 10 parts of pigments (pearl luster powder, Huake pearlescent pigment) are added, after stirring for 20-30min; Reduce the speed to 400r / min, then add 0.05 parts of defoamer (Foamex 902W, TEGO company), 5 parts of adhesion promoter (POL-272, Shenzhen Meishimeike New Material Co., Ltd.), salt spray resistance additive 3 parts (ZT-719, Beijing Zhitu Chemical Co., Ltd.), 10...

Embodiment 2

[0047] Under the rotating speed of 500r / min, in terms of mass parts, add 22 parts of tap water, 25 parts of modified water-soluble acrylic resin (RB-306, Rongbiao paint, Shunde District, Foshan City), 3 parts of cosolvent (ethylene glycol Butyl ether, Dow Chemical), 0.2 part of wetting and dispersing agent (SN-5040, Shenzhen Haichuan Chemical Co., Ltd.) and 0.3 part of wetting and dispersing agent (Disperbyk180, BYK Company), 0.3 part of pH regulator (ammonia water, Dow Chemical ), 0.1 parts of defoamer (BYK-019, BYK company), after stirring for 5 minutes, adjust the speed to 1000r / min, add 12 parts of pigments (pearl powder, Huake pearl pigment), and stir for 20-30 minutes; Reduce to 400r / min, then add 0.1 part of defoamer (BYK-025, BYK company), 3 parts of adhesion promoter (WACH308, Hanyang Trading), 2 parts of salt spray resistance additive (ES-431, Guangzhou Fangjing Trading Co., Ltd.’s salt spray agent), 10 parts of amino resin (717, Ineos), 2 parts of cosolvent (n-butan...

Embodiment 3

[0050] Under the rotating speed of 600r / min, in terms of mass parts, add 14 parts of tap water, 20 parts of modified polyester resins (SKW001, Shanghai Chaoyu Chemical Materials Co., Ltd.), 3 parts of cosolvents (ethylene glycol, Dow Chemical), 0.3 parts of wetting and dispersing agent (Hydropalat 3275, Shenzhen Haichuan Chemical Co., Ltd.) and 0.3 parts of wetting and dispersing agent (Orotan 1288, Rohm and Haas, USA), 0.4 parts of pH regulator (AMP95, Dow Chemical) , 0.1 parts of defoamer (Defom W-0505, Deqian Chemical), after stirring for 5 minutes, adjust the speed to 1000r / min, add 15 parts of pigment (CR-826, Kemeiqi), and stir for 20-30 minutes; Reduce the speed to 400r / min, then add 0.1 part of defoamer (DefomW-0505, Deqian Chemical), 3 parts of adhesion promoter (WACH308, Hanyang Trading), 2 parts of salt spray resistance additive (ZT-719 , Beijing Zhitu Chemical Co., Ltd.), 10 parts of amino resin (072, BASF), 2 parts of cosolvent (alcohol ester 12, Dow Chemical) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com