Plugging agent for fractured-vuggy oil reservoir

A technology of fracture-hole type and plugging agent, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of contradiction between strength and selectivity, high density of plugging agents, etc., to prevent leakage, ensure injection safety, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

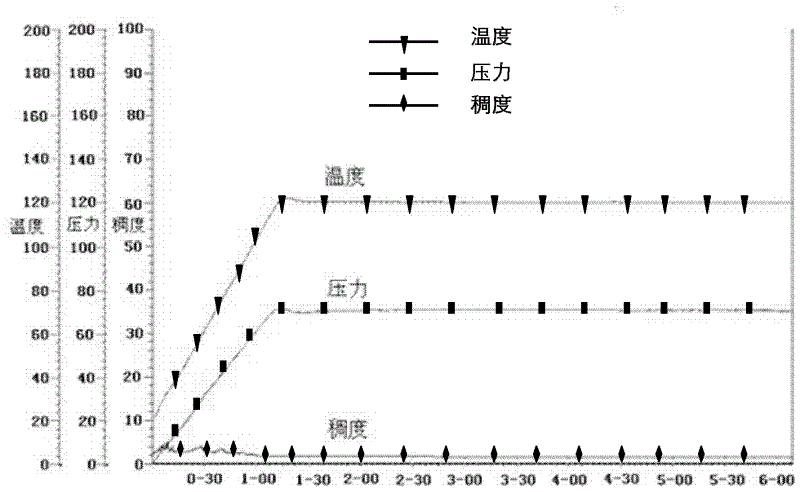

Embodiment 1

[0044] Cement (D 50 1μm) 45g (5.24% mass), micro silicon (D 50 60nm) 26g (3.03% quality), sodium bentonite 40g (4.66% quality), hydroxyethyl cellulose (viscosity-average molecular weight at 1 million) 4.7g (0.55% quality) are mixed, are made into mixed ash; 1.5g (0.17% quality) of calcium amine tetramethylene phosphonate, 0.8g (0.09% quality) of sodium carbonate aqueous solution of mass concentration 1% join in the paddle type stirrer that 741g water (86.26% quality) is housed, Make a mixed solution, then slowly add the mixed ash into the mixed solution, stir evenly, and form the laboratory plugging agent sample 1#. The water-cement ratio of this sample is 6.28.

Embodiment 2

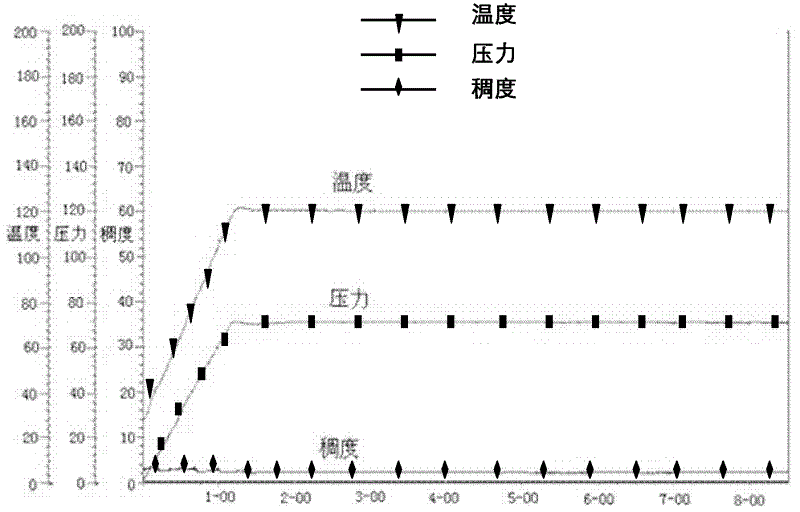

[0046] Cement (D 50 0.9μm) 49g (5.74% mass), micro silicon (D 50 50nm) 28g (3.28% quality), sodium bentonite 43g (5.03% quality), hydroxyethyl cellulose (viscosity-average molecular weight at 1 million) 4.6g (0.54% quality) are mixed, are made into mixed ash; 1.6g (0.19% quality) of sodium amine tetramethylene phosphonate, 0.86g (0.10% quality) of sodium carbonate aqueous solution with a mass concentration of 1% were added to the paddle stirrer that 727g water (85.12% quality) was housed, Make a mixed solution, then slowly add the mixed ash into the mixed solution, stir evenly, and form the laboratory plugging agent sample 2#. The water-cement ratio of this sample is 5.72.

Embodiment 3

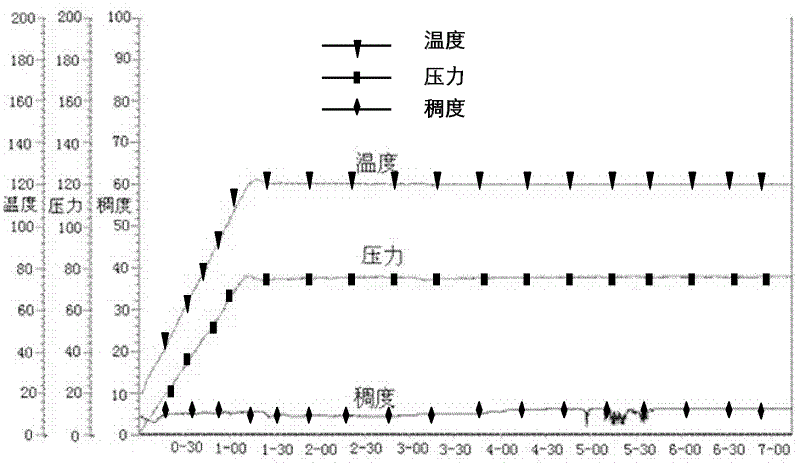

[0048] Cement (D 50 0.9μm) 54g (6.38% mass), micro silicon (D 50 40nm) 31g (3.66% quality), sodium bentonite 46g (5.43% quality), hydroxyethyl cellulose (viscosity-average molecular weight at 1,000,000) 4.5g (0.54% quality) mix, be made into mixed ash; Amine pentamethylene phosphonic acid 2.0g (0.24% quality), the sodium carbonate aqueous solution 0.92g (0.11% quality) of mass concentration 1% join in the paddle type stirrer that 708g water (83.64% quality) is housed, prepare to form a mixed solution, and then slowly add the mixed ash into the mixed solution, and stir evenly to form laboratory plugging agent sample 3#. The water-cement ratio of this sample is 5.11.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com