Safety interlocking protection system used for powdered coal pressure gasification process and method

A technology for pressurized gasification and safety interlocking of pulverized coal, applied in the coal chemical industry, can solve the problems of unverifiable system safety and reliability, failure to obtain SIL safety level certification, and short scanning cycle system response, and achieves strict program design. The effect of perfect, safe and reliable design, and strict program logic design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

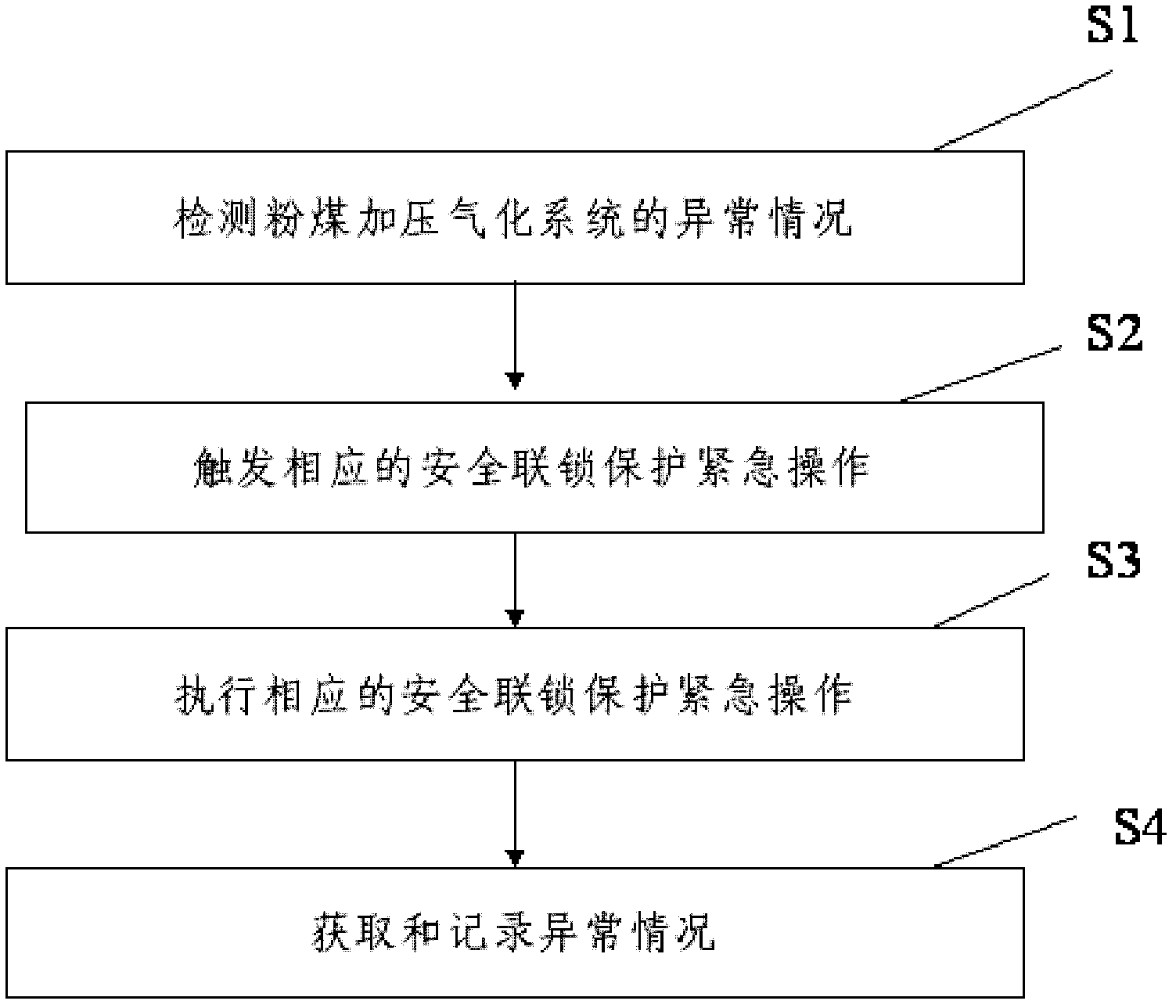

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

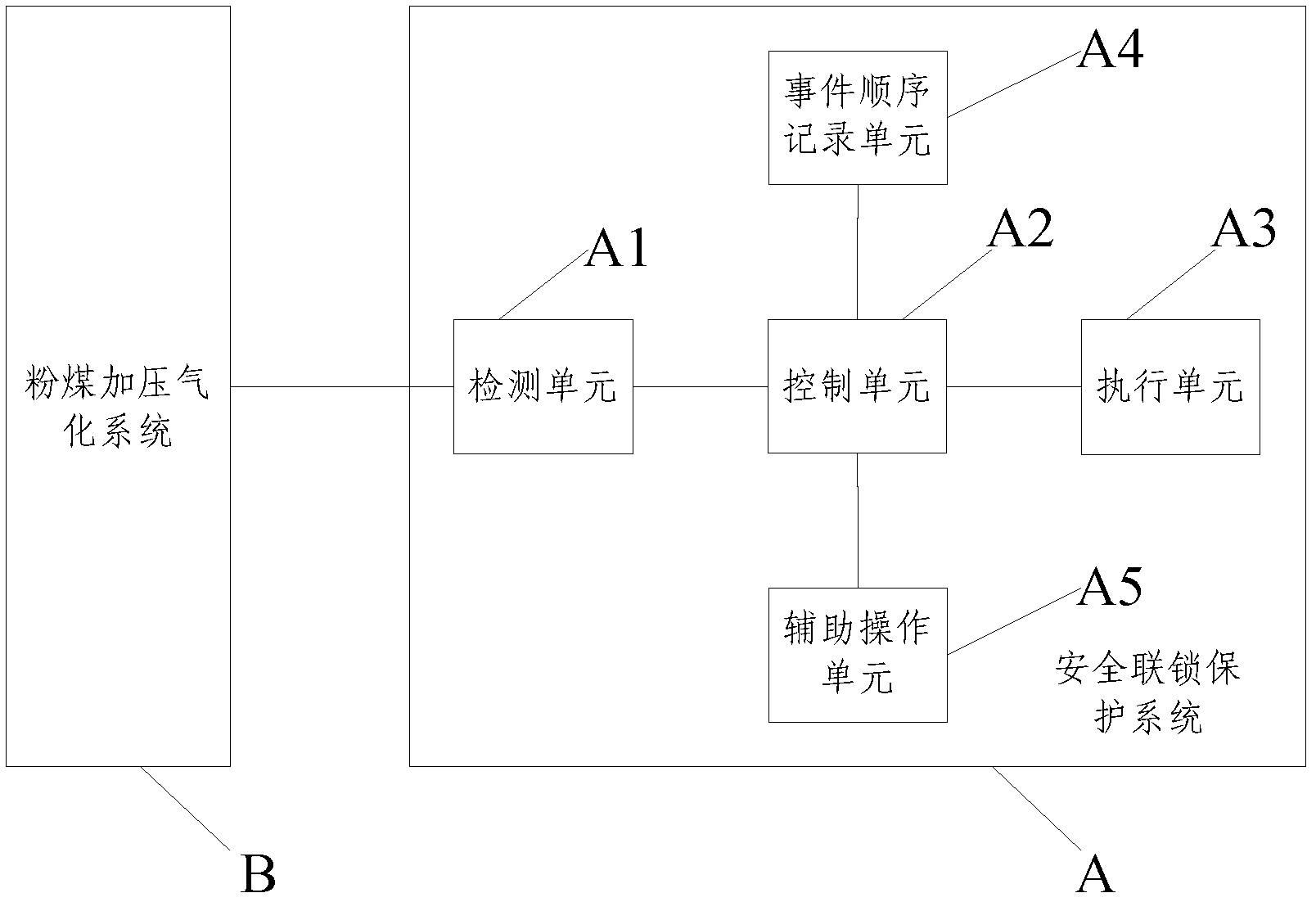

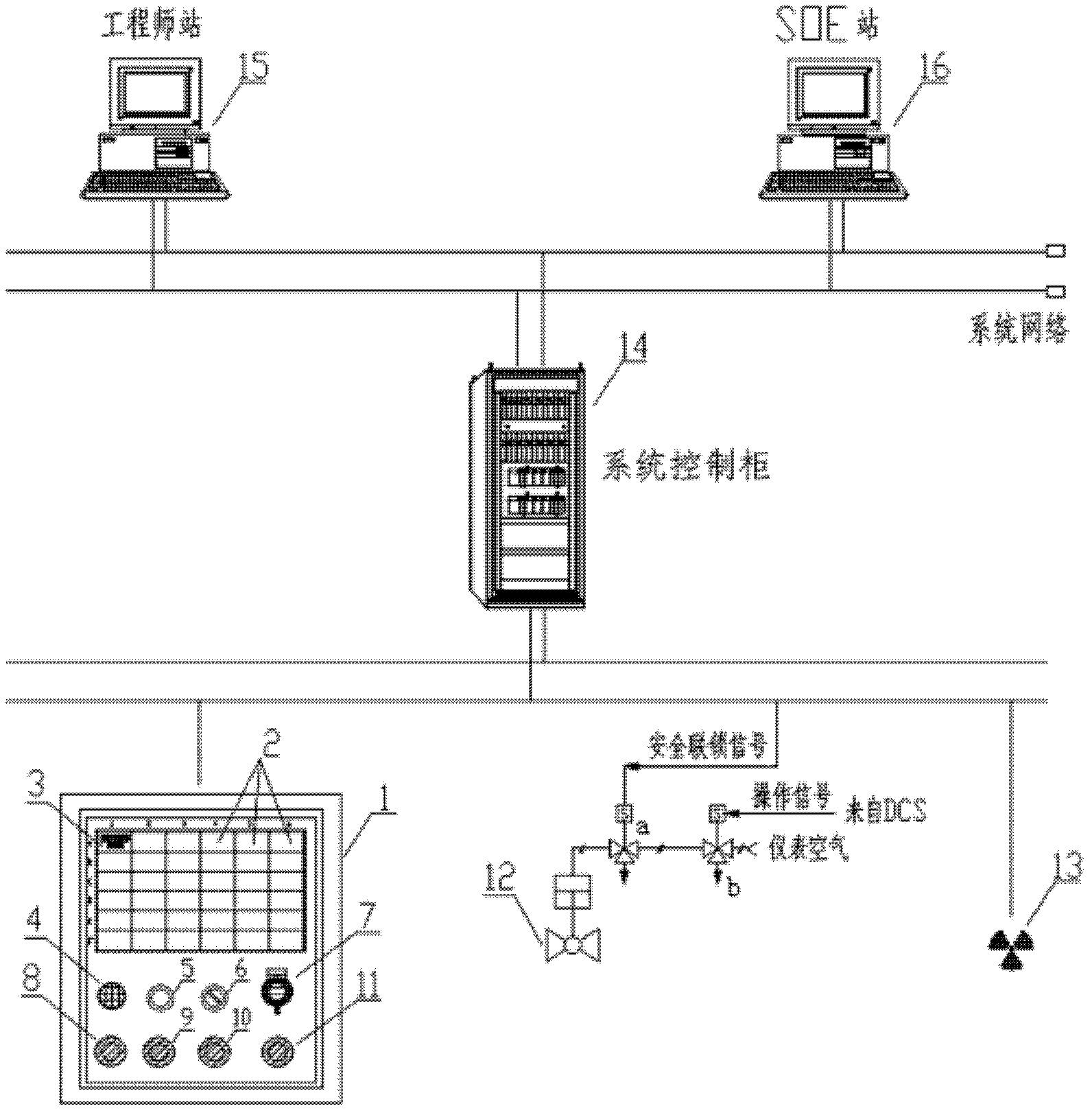

[0028] figure 1 and figure 2 An exemplary block diagram and an exemplary structural diagram of the safety interlock protection system of the present invention are respectively shown.

[0029] Such as figure 1 As shown, according to this embodiment, the safety interlock protection system A of the present invention includes a detection unit A1, a control unit A2, an execution unit A3, and a sequence of events recording (SOE) unit A4. In addition, according to needs, the safety interlock protection system A of the present invention may also include an auxiliary operation unit A5.

[0030] Among them, the detection unit A1 is used to detect the abnormal situation of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com