Method for extracting amphoteric heavy metal by adopting incineration fly ash as low-grade heavy metal

A technology for incinerating fly ash and heavy metals, applied in the direction of improving process efficiency, etc., can solve the problems of lack of universal applicability in incinerating fly ash, limited improvement of heavy metal fixation rate, inability to break dioxin, etc., and achieve good universal applicability and low cost Low, easy-to-select effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

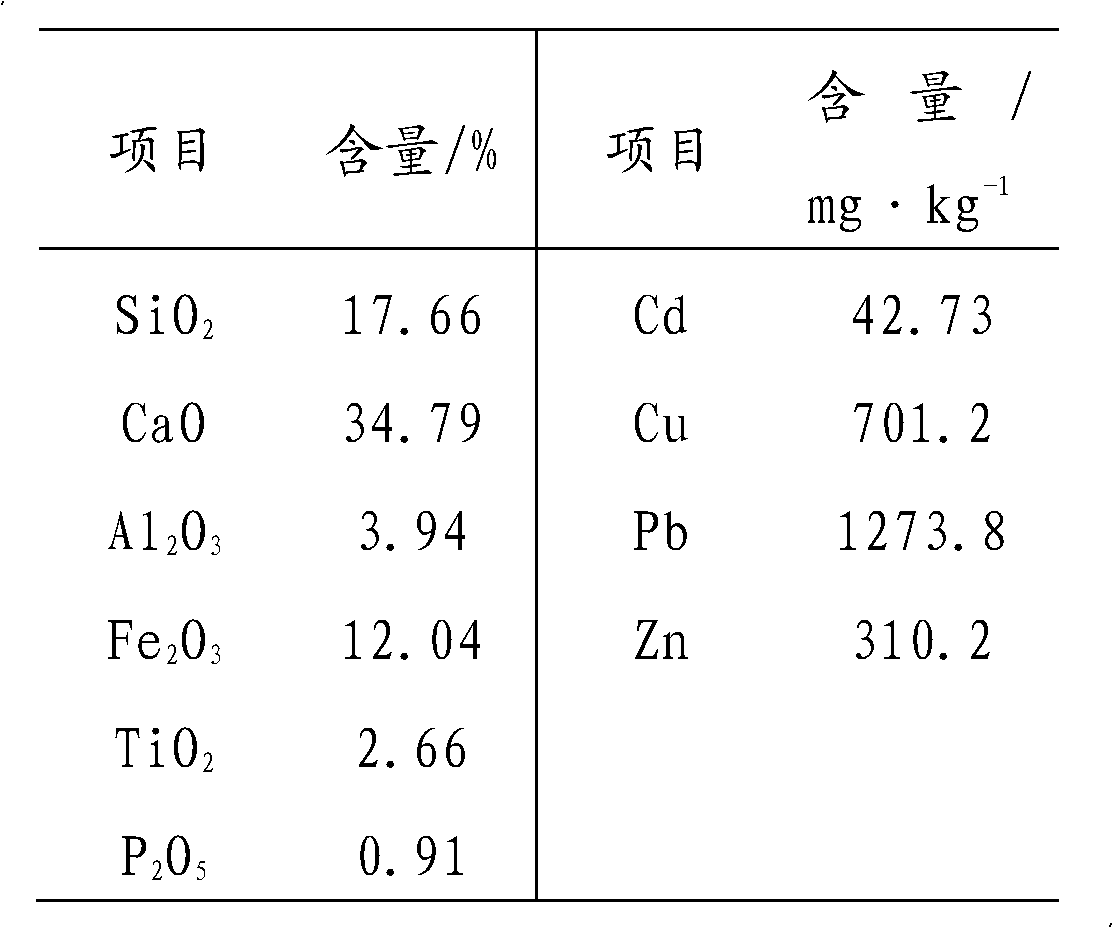

[0022] Low chlorine content incineration fly ash samples, the composition is shown in Table 1, take incineration fly ash 100g, after adding different proportions of NaCl (5%, 10% (calculated according to the weight % of Cl)), and then in the box-shaped resistance furnace The sample was roasted at a constant temperature of 1000°C and 1100°C for 4 hours, and the sample was cooled naturally in the air, and then the extraction rate of amphoteric heavy metals was analyzed. When the NaCl content was 0, 5% and 10%, the extraction rate of Cd was 86.9%, 97.6% and 100% at the calcination temperature of 1000℃. When the calcination temperature is 1100℃, they are 90.1%, 93.2% and 100%, respectively. The extraction rate of Pb increased from 85.7% to 100% at the calcination temperature of 1000°C. When the calcination temperature is 1100℃, it increases from 90.8% to 100% respectively. The extraction rate of Zn increased from 23.9% to 73.8% at the calcination temperature of 1000℃. It increa...

Embodiment 2

[0026] Incineration fly ash samples are shown in Table 1, and different proportions of CaCl were added 2 After (5%, 10% (calculated according to the weight % of Cl)), the implementation method is shown in Example 1.

[0027] When CaCl 2 When the contents are 0, 5% and 10% respectively, the extraction rate of Cd is 86.9%, 91.6% and 100% at the calcination temperature of 1000℃. The extraction rates of Pb were 85.7%, 91.4% and 100% respectively at the calcination temperature of 1000°C. The extraction rate of Zn increased from 23.9% to 72.3% at the calcination temperature of 1000℃.

Embodiment 3

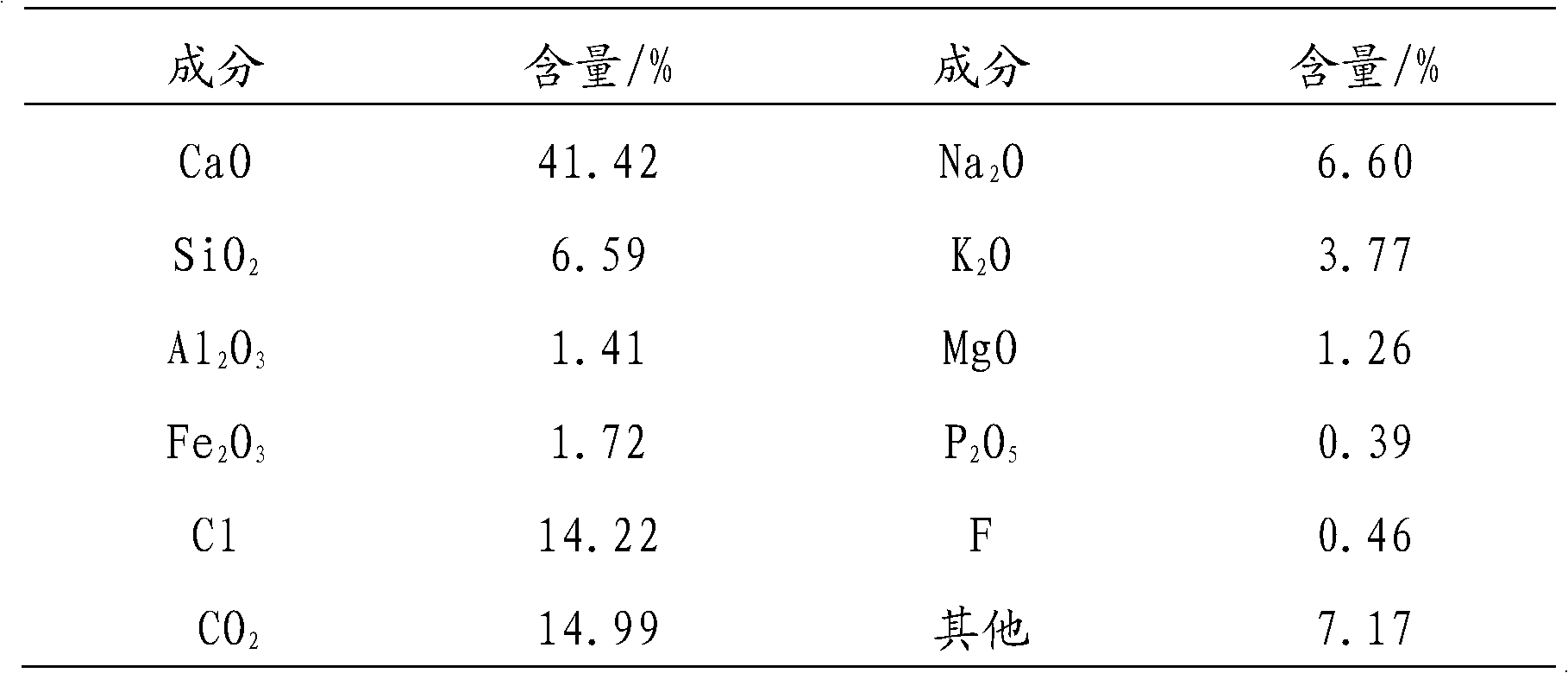

[0029] The samples of incineration fly ash with high chlorine content are shown in Table 2. 100g of fly ash was placed in a corundum porcelain boat (the composition is Al 2 o 3 , the length, width and height are 10cm×10cm×1.2cm), the corundum porcelain boat is placed in a fixed furnace that has reached a predetermined temperature for firing experiments. The preset temperature is 900°C and 1100°C, and the atmosphere is air atmosphere. The roasting time is 12.5min, 30min, 60min, 1.5h, 2h, 3h. When the Cl content in the original incineration fly ash is high, that is, 14.22%, there is no need to add inorganic chlorinating agents to the incineration fly ash. At 900°C and the roasting time is 1 hour, the extraction rate of Pb is about 80%, and the extraction rate of Cu is about 80%. The extraction rate reached 50%, and after the roasting temperature was increased to 1100°C, the roasting time was only 12.5 minutes, and the extraction rate of Pb was over 90%, and the extraction rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com