Carbonless copy paper

A carbonless copy paper and base paper technology, applied in paper, papermaking, paper coating, etc., can solve problems such as white spots, affecting the quality of carbonless copy paper, and fiber exposure, so as to improve color development and printing, reduce white spots, and fill The effect of holes in the paper surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

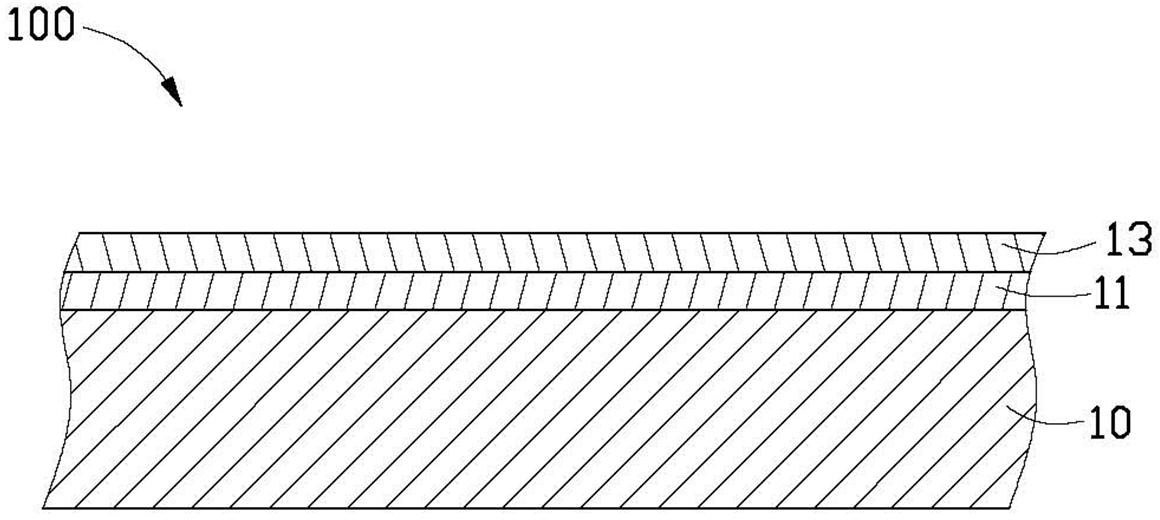

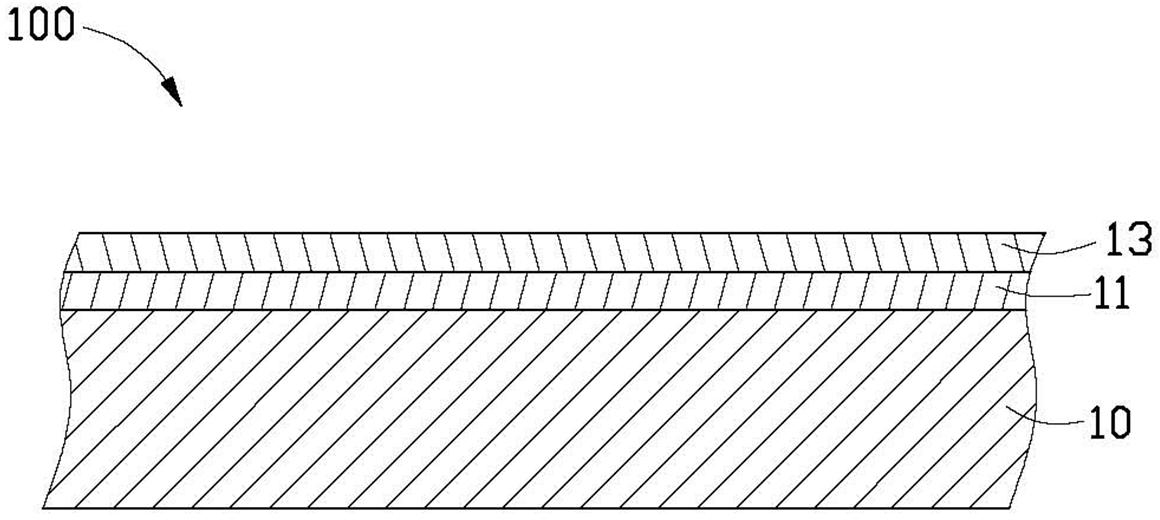

[0015] A carbonless copy paper 100 of a preferred embodiment of the present invention (such as figure 1 Shown) the preparation method, it comprises the steps:

[0016] (1) Provide initial raw paper 10

[0017] The base paper 10 is the base paper of common carbonless copy paper, preferably one or both of hardwood pulp (LBKP), softwood pulp (NBKP) and chemithermomechanical pulp (BCTMP) and hardwood pulp The mixed pulp is made by papermaking, and the mass percentage of hardwood pulp is 70-100%, the mass percentage of softwood pulp is 0-10%, and the mass percentage of chemical thermomechanical pulp is 0-20% . The slurry of the papermaking base paper 10 is added with appropriate chemicals, dry strength agents, etc. to ensure the strength of the base paper 10 and to ensure the smooth progress of the subsequent coating process.

[0018] For the physical property index of the base paper 10, it is mainly necessary to control its sizing degree, COBB value (paper water absorption perf...

Embodiment 1

[0044] Base paper 10: 100% hardwood pulp is used as the pulp, and its grammage is 46gsm (gram per square meter, gram per square meter).

[0045] The first coating liquid formula: 60 parts of calcium carbonate, 40 parts of adhesive (latex, starch, etc. mixed at a ratio of 2:3), and 10 parts of cationic paraffin emulsion.

[0046] The second coating solution formula: 60 parts of calcium carbonate as pigment, 40 parts of china clay, 12 parts of tapioca starch as starch, 12 parts of styrene-butadiene latex as latex, 22 parts of zinc salicylate as developer, and sulfonated surfactant as 0.5 part of succinate, 0.8 part of sodium hexametaphosphate as dispersant.

Embodiment 2

[0048] Base paper 10: The pulp is a mixed pulp of 90% hardwood pulp and 10% chemical thermomechanical pulp, and the grammage is 46gsm.

[0049] The first coating liquid formula: 55 parts of calcium carbonate, 45 parts of adhesive, and 5 parts of cationic paraffin emulsion are used.

[0050] The second coating solution formula: the same as the second coating solution in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com