Auto-cascade jet type refrigerator

A technology of ejector and refrigerator, which is applied in the direction of refrigerator, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of high operating cost and complex structure, and achieve the effect of improving refrigeration performance, reducing compression ratio, and improving ejector efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

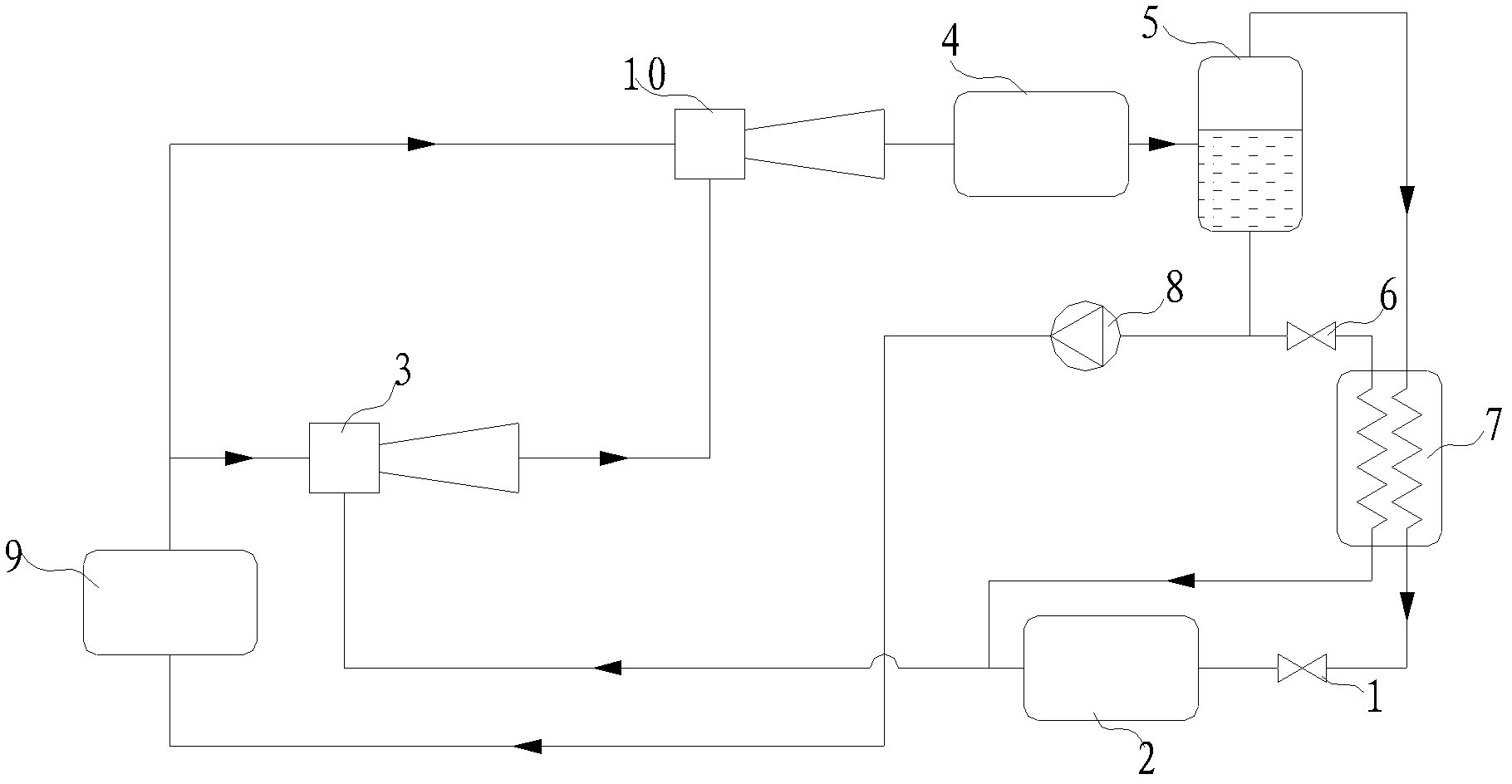

[0033] This embodiment is an improvement carried out on the basis of Example 1, as figure 2 shown in figure 1 On the basis of the system shown, the first ejector 3 and the second ejector 10 are connected in series and then connected to the condenser 4 . There is a pipeline communicating between the outlet of the first generator 9 and the inlet of the working fluid of the second injector 10 .

[0034] The specific connection is: a second injector 10 is provided on the pipeline between the first injector 3 and the first condenser 4; the working fluid inlet of the second injector 10 communicates with the working fluid outlet of the first generator 9, and the second injector 10 communicates with the working medium outlet of the first generator 9, The injection fluid inlet of the second injector 10 communicates with the injection outlet of the first injector 3 , and the injection outlet of the second injector 10 communicates with the working medium inlet of the first condenser 4 ...

Embodiment 3

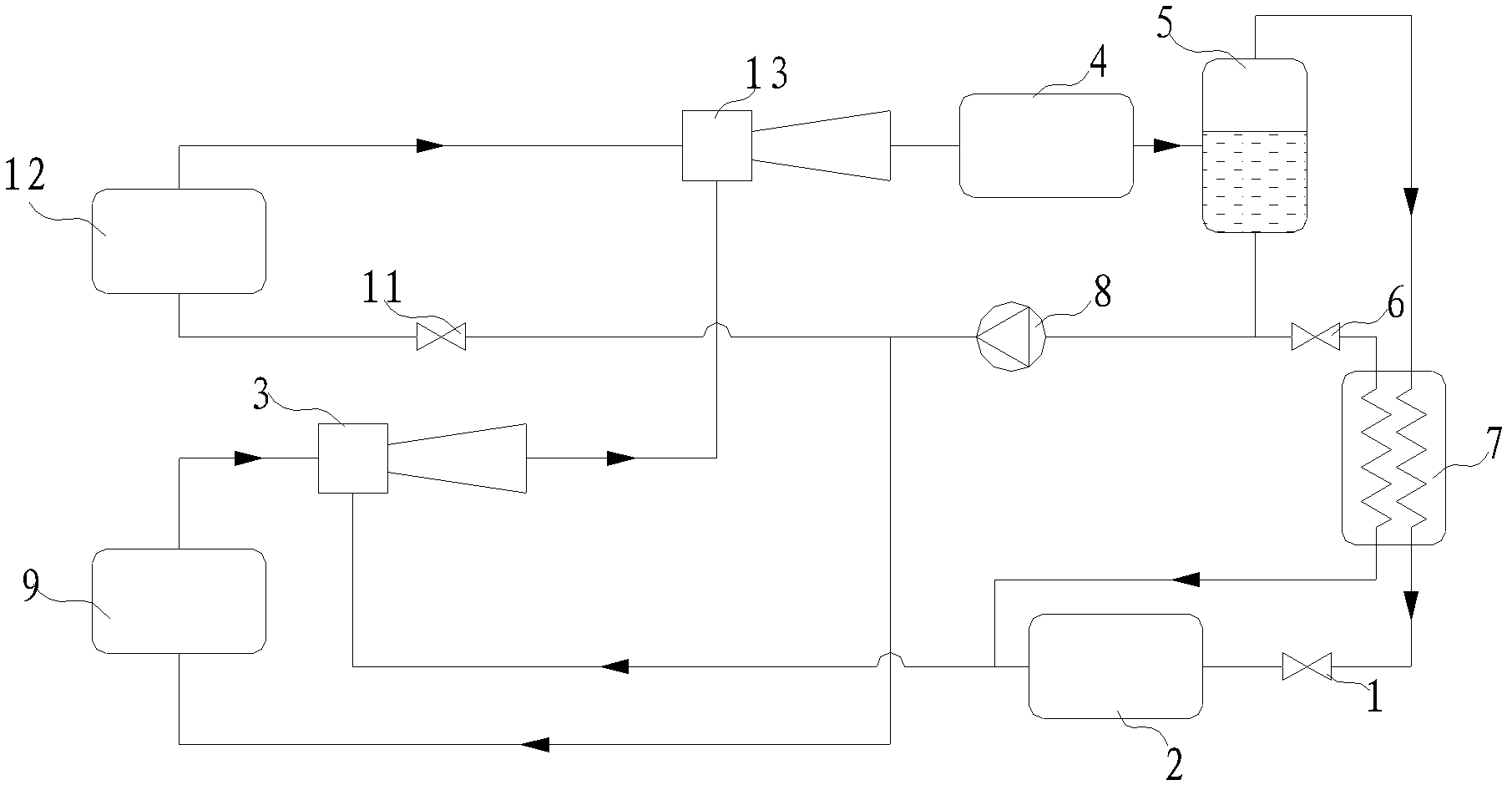

[0037] Such as image 3 As shown, this implementation is an improvement on the basis of Example 1. The third throttling element 11 and the second generator 12 are connected in series between the outlet of the first circulation pump 8 and the inlet of the working fluid of the third injector 13 .

[0038] The specific connections are: the working fluid inlet of the third injector 13 communicates with the working medium outlet of the second generator 12, the injection fluid inlet of the third injector 13 communicates with the injection outlet of the first injector 3, and the third injector The injection outlet of 13 communicates with the working medium inlet of the first condenser 4; the third throttling element 11 is arranged on the pipeline between the working medium outlet of the first circulating pump 8 and the working medium inlet of the second generator 12. All the other parts are connected with the embodiment 1.

[0039] Compared with Example 1, the working fluid flow in ...

Embodiment 4

[0041] Such as Figure 4 As shown, this embodiment is an improvement on the basis of Embodiment 4, wherein the third throttling element 11 is located on the pipeline between the first generator 9 .

[0042] The specific connection is: the working medium inlet of the second generator 12 communicates with the working medium outlet of the first circulation pump 8 . The working fluid outlet of the third throttling element 11 is connected with the working fluid inlet of the first generator 9 , and the working fluid inlet of the third throttling element 11 is connected with the working fluid outlet of the first circulating pump 8 . All the other parts are connected with the embodiment 1. All the other parts are connected with embodiment 3.

[0043] Compared with Example 4, the difference in working fluid flow in this example is that part of the liquid at the outlet of the first circulating pump 8 directly enters the second generator 12, and becomes a high-pressure gas after being ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com