Air conditioner heat pump unit with antifreeze solution regenerated heat recovery device

A heat recovery device and antifreeze solution technology, applied in heat recovery systems, refrigerators, refrigeration components, etc., can solve problems such as limited application areas, large solution storage space, and freezing of refrigerants to avoid frosting or The effect of freezing, increasing the concentration of the solution, and increasing the evaporation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

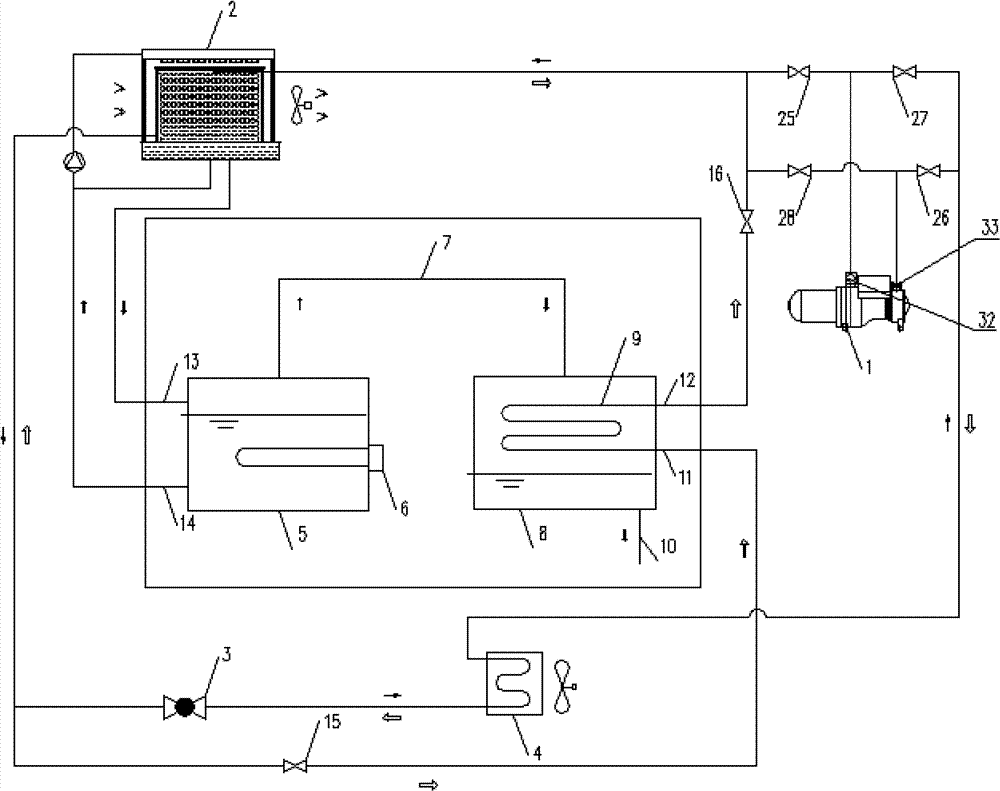

[0034] In this embodiment, an air-conditioning heat pump unit with an antifreeze solution regenerative heat recovery device, such as figure 1 As shown, it includes a compressor 1, an evaporative condenser 2, at least one throttling device 3, at least one evaporator 4 and an antifreeze solution regeneration heat recovery device, and the interface at one end of the compressor 1 is respectively connected to the gas pipe of the evaporative condenser 2 and the gas pipe of the evaporator 4, the interface at the other end of the compressor 1 is respectively connected to the gas pipe of the evaporative condenser 2 and the gas pipe of the evaporator 4, and the connecting pipe where the throttling device 3 is located is respectively connected to the liquid pipe of the evaporator 4 and the liquid pipe of the evaporative condenser 2; the cooling water system of the evaporative condenser 2 is equipped with an antifreeze solution regeneration heat recovery device;

[0035] The antifreeze so...

Embodiment 2

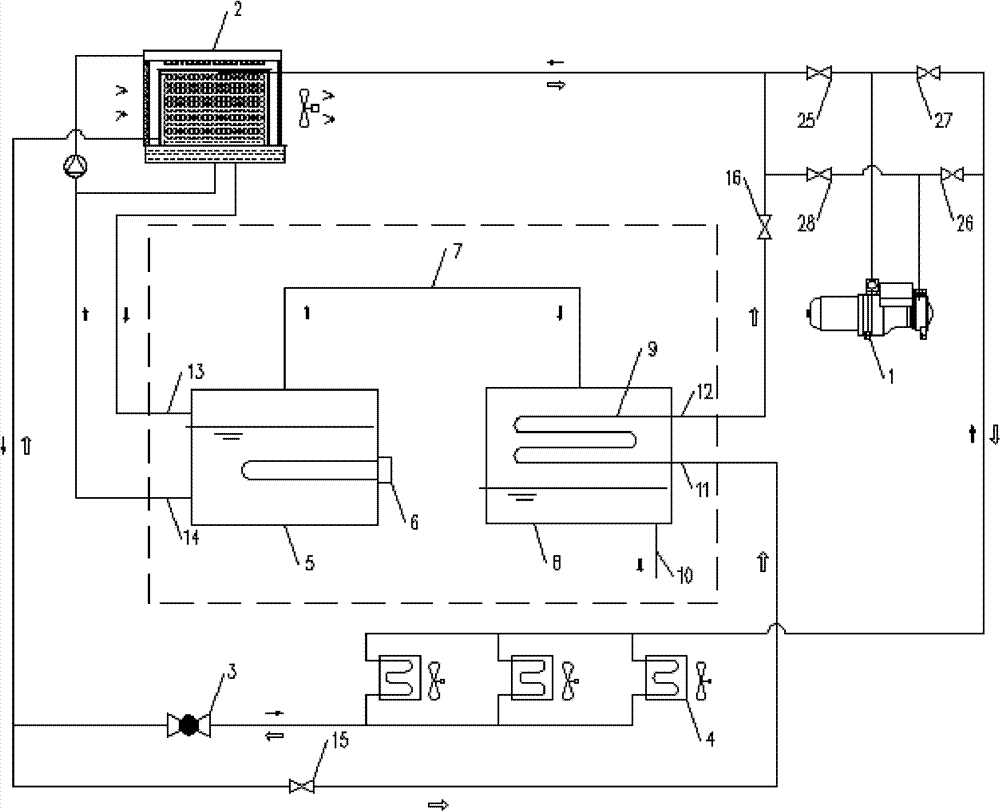

[0039] In this embodiment, an air-conditioning heat pump unit with an antifreeze solution regenerative heat recovery device, such as figure 2 As shown, compared with Example 1, the difference is that a plurality of evaporators 4 are arranged in parallel. After a plurality of evaporators are connected in parallel, one end of the evaporator group is connected to the compressor 1, and the other end of the evaporator group is connected to the compressor 1. One end is connected with the throttling device 3 .

Embodiment 3

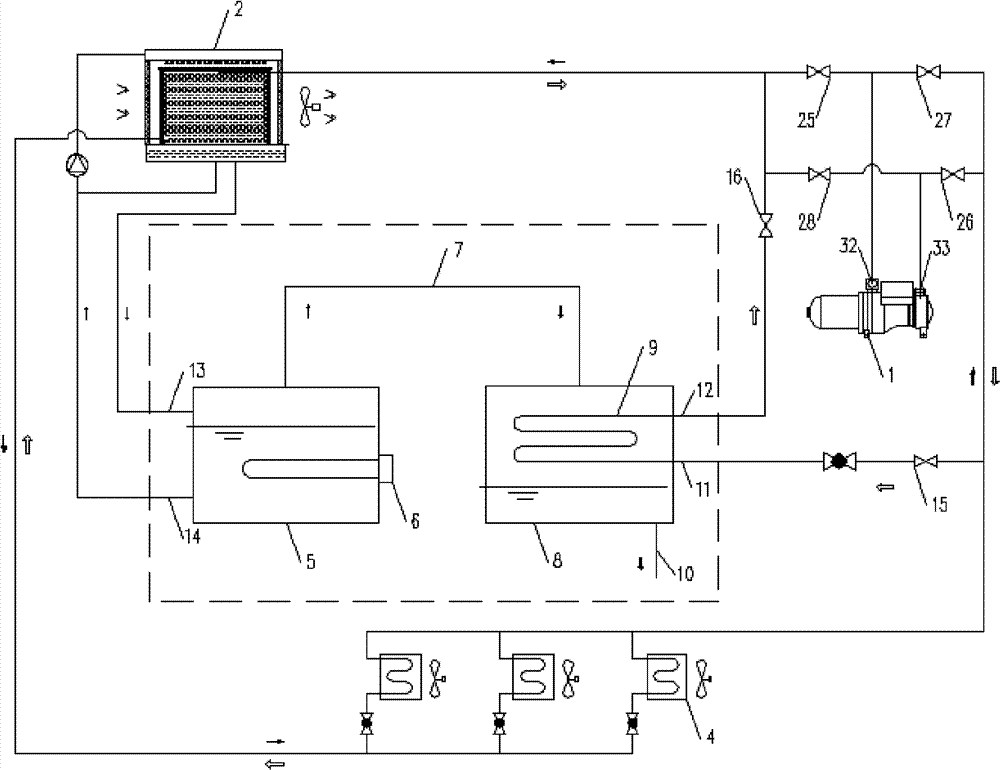

[0041] In this embodiment, an air-conditioning heat pump unit with an antifreeze solution regenerative heat recovery device, such as image 3 As shown, compared with Embodiment 1, the difference is that a plurality of throttling devices 3 are provided, so that the flow of refrigerant entering the first heat exchanger 9 and the evaporator 4 can be accurately controlled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com