Preparation method of tantalate photocatalytic material

A photocatalytic material, tantalate technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low activity, poor stability and long synthesis time, and achieve hydrogen production. The effect of high speed, good stability and shortened preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

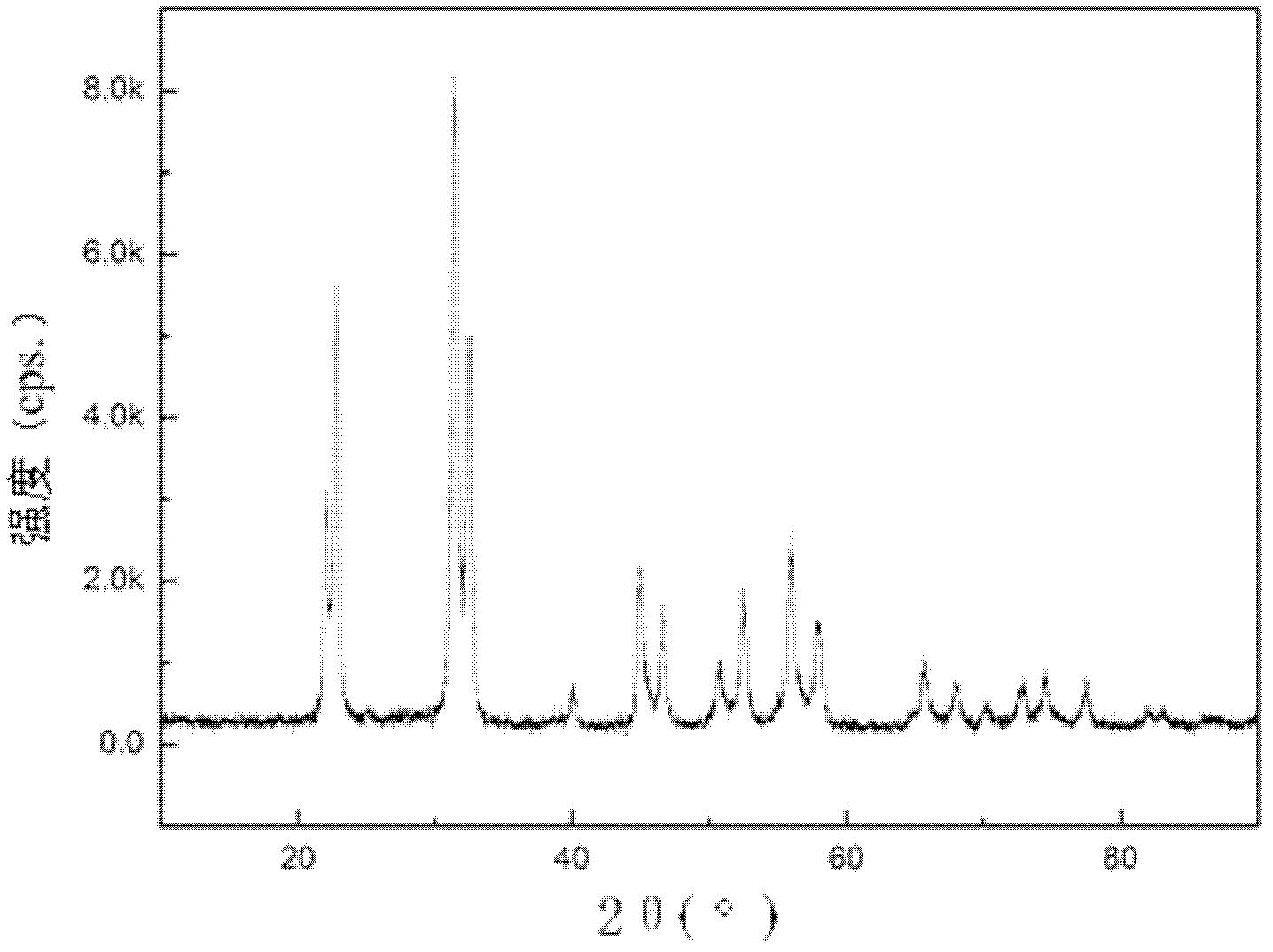

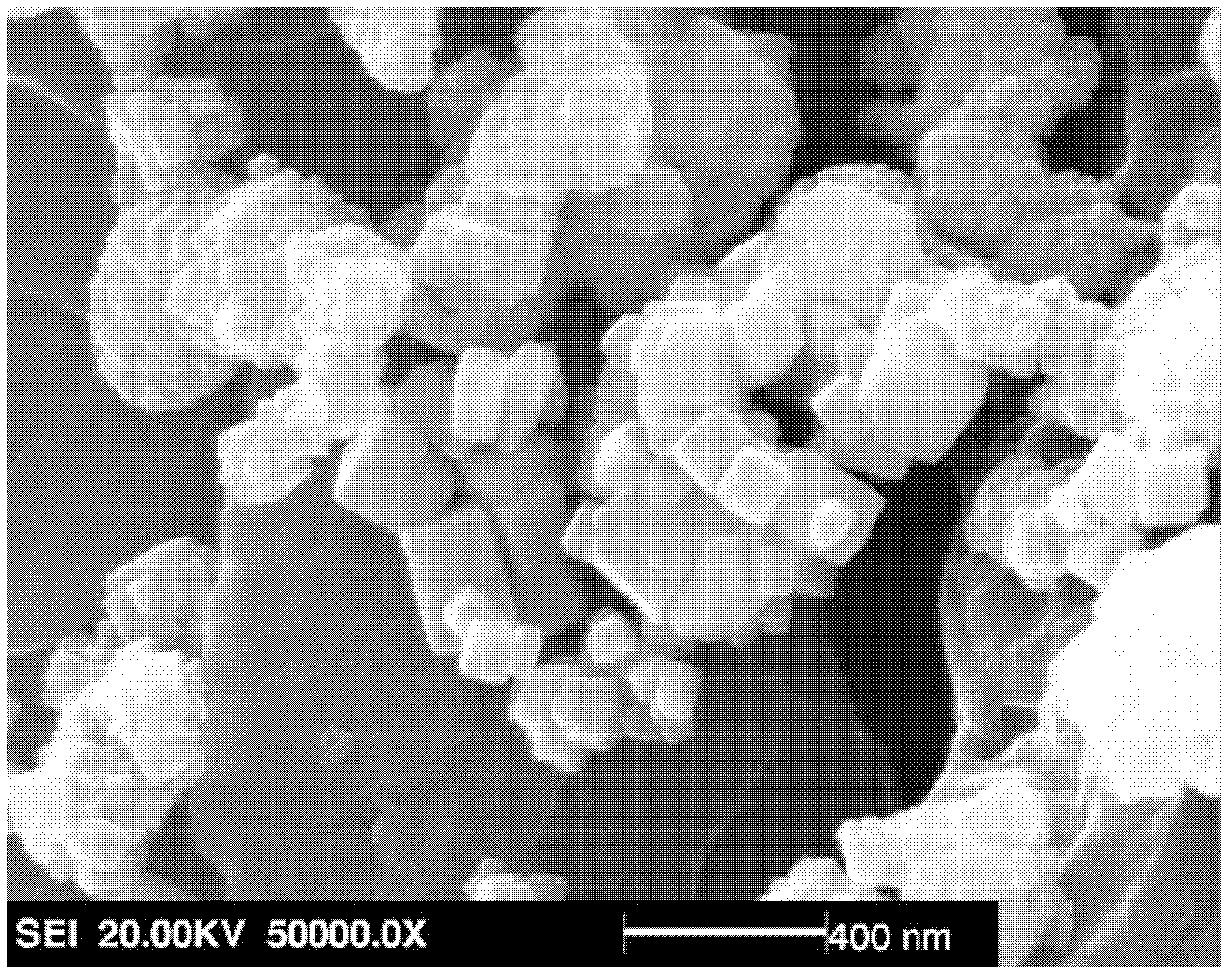

[0012] Specific embodiment 1: The preparation method of a tantalate photocatalytic material of this embodiment is carried out in the following steps:

[0013] 1. According to the molar ratio of NaCl and KCl of 0.45:0.55, weigh NaCl and KCl and ball mill them to a particle size ≤10μm to obtain eutectic molten salt powder;

[0014] 2. Press Na 2 CO 3 , K 2 CO 3 And Ta 2 O 5 The molar ratio is 1:1:1, weighing Na 2 CO 3 , K 2 CO 3 And Ta 2 O 5 And mix evenly, and then grind to a particle size ≤10μm to obtain raw material powder;

[0015] 3. The raw material powder obtained in step 2 and the eutectic molten salt powder obtained in step 1 are uniformly mixed in a mass ratio of 1: (1 to 3) to obtain a mixed powder;

[0016] 4. Place the mixed powder obtained in step 3 in a corundum crucible, then put the crucible in a high-temperature furnace, and fire at 700-850℃ for 1 to 4 hours. The product obtained is washed with deionized water and centrifuged. After drying, the tantalate photocatalytic...

specific Embodiment approach 2

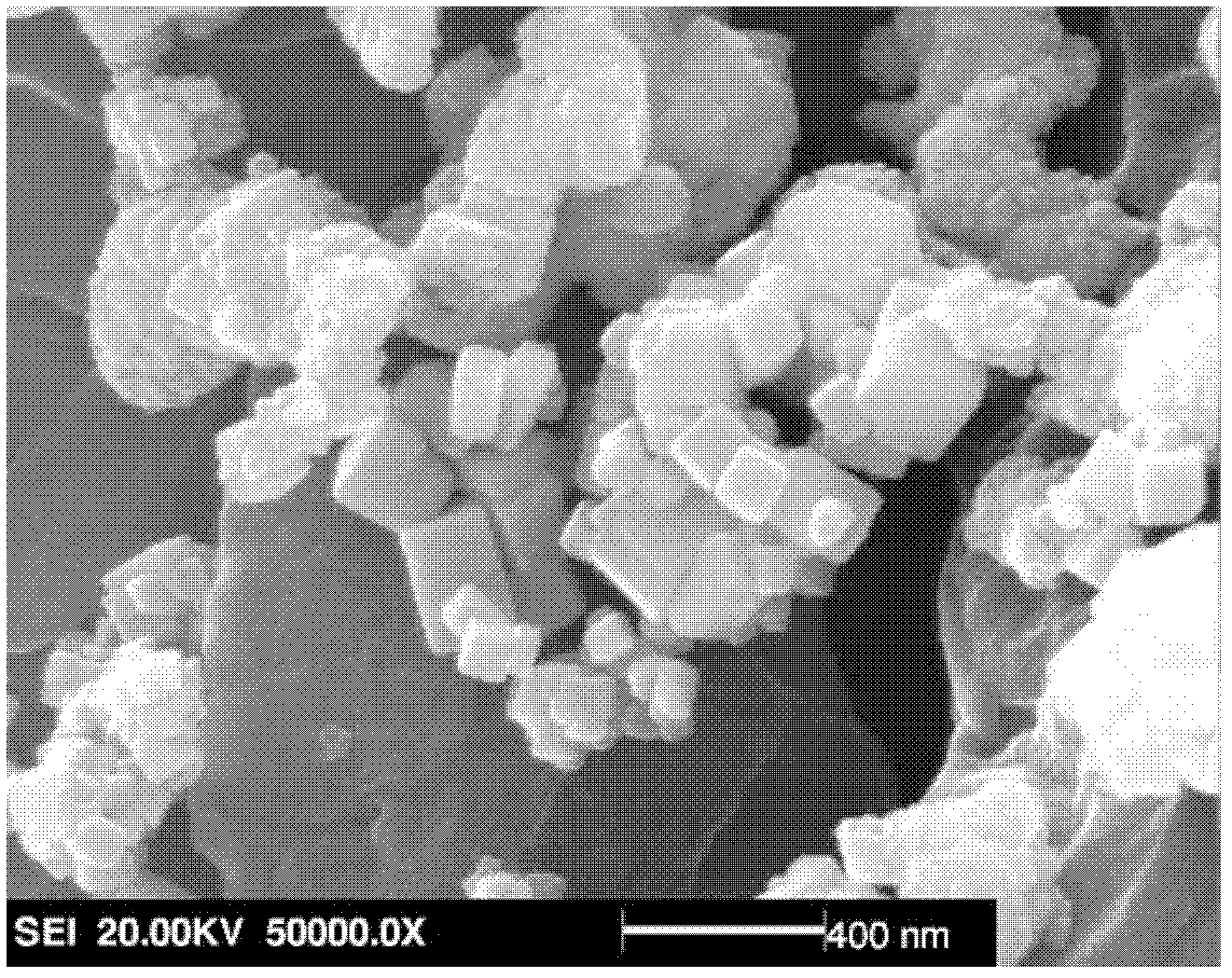

[0018] Specific embodiment two: this embodiment is different from specific embodiment one in that in step three, the mass ratio of the raw material powder and the eutectic molten salt powder is 1: (1.5-2.8). Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: This embodiment is different from specific embodiment one in that the mass ratio of the raw material powder and the eutectic molten salt powder in step three is 1:2. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com