High pressure hydrogenation naphthenic lubricating oil light stabilizer composition and application thereof

A technology of naphthenic lubricating oil and high-pressure hydrogenation, which is used in lubricating compositions, additives, petroleum industry, etc., can solve problems such as poor effect, and achieve the effect of slowing down oxidative degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

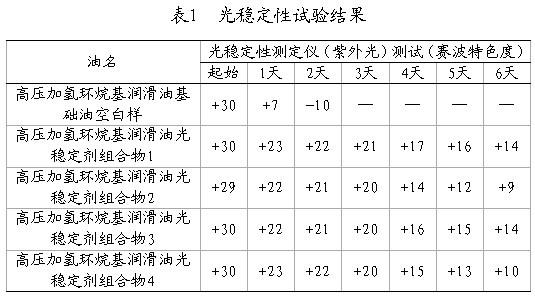

Examples

Embodiment 1

[0035] A kind of high-pressure hydrogenation naphthenic lubricating oil light stabilizer, described a kind of high-pressure hydrogenation cycloalkyl lubricating oil light stabilizer is made of ultraviolet absorber UV-120 (3,5-di-tert-butyl-4-hydroxybenzene Formic acid-2,4-di-tert-butylphenyl ester), hindered amine light stabilizer 3,5-bis(1,1-dimethylethyl)-4-hydroxyphenylpropionate octadecyl ester and three [2,4-di-tert-butylphenyl] a composition composed of phenylphosphite chelating agent;

[0036] Calculated by weight percentage, wherein the ultraviolet light absorber UV-120 (3,5-di-tert-butyl-4-hydroxybenzoic acid-2,4-di-tert-butylphenyl ester) and hindered amine light stabilizer 3,5 - The total content of both octadecyl bis(1,1-dimethylethyl)-4-hydroxyphenylpropionate in a high-pressure hydrogenated cycloalkyl lubricating oil light stabilizer composition is 80%;

[0037] The content of tris[2,4-di-tert-butylphenyl]phenylphosphite chelating agent in a high-pressure hydrog...

Embodiment 2

[0041]A high-pressure hydrogenated cycloalkyl lubricating oil light stabilizer, the high-pressure hydrogenated cycloalkyl lubricating oil light stabilizer is composed of ultraviolet light absorber UV328 (2-[2-hydroxyl-3,5-bis(1, 1-dimethylpropylphenyl)]-2H-benzotriazole), hindered amine light stabilizer 3,5-bis(1,1-dimethylethyl)-4-hydroxyphenylpropionic acid deca A composition composed of octaalkyl esters and tris[2,4-di-tert-butylphenyl]phenylphosphite chelating agent;

[0042] Calculated by weight percentage, wherein the ultraviolet light absorber UV328 (2-[2-hydroxy-3,5-bis(1,1-dimethylpropylphenyl)]-2H-benzotriazole) and hindered amines Light stabilizer 3,5-bis(1,1-dimethylethyl)-4-hydroxyphenylpropionate octadecyl ester in a high-pressure hydrogenated cycloalkyl lubricating oil light stabilizer composition The total content is 80%;

[0043] The content of tris[2,4-di-tert-butylphenyl]phenylphosphite chelating agent in a high-pressure hydrogenated cycloalkyl lubricating...

Embodiment 3

[0047] A high-pressure hydrogenated cycloalkyl lubricating oil light stabilizer, the high-pressure hydrogenated cycloalkyl lubricating oil light stabilizer is composed of ultraviolet light absorber UV234 (2-(2H-benzotriazole-2)-4, 6-bis(1-methyl-1-phenylethyl)phenol), hindered amine light stabilizer 3,5-bis(1,1-dimethylethyl)-4-hydroxyphenylpropanoic acid octadecane A composition composed of base ester and tris[2,4-di-tert-butylphenyl]phenylphosphite chelating agent;

[0048] Calculated by weight percentage, wherein UV234 (2-(2H-benzotriazole-2)-4,6-bis(1-methyl-1phenylethyl)phenol) and hindered amine light stabilizer The total content of the two agents 3,5-bis(1,1-dimethylethyl)-4-hydroxyphenylpropionate octadecyl ester in a high-pressure hydrogenated cycloalkyl lubricating oil light stabilizer composition 90%;

[0049] The content of tris[2,4-di-tert-butylphenyl]phenylphosphite chelating agent in a high-pressure hydrogenated cycloalkyl lubricating oil light stabilizer comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com