Low-nickel and high-iron copper alloy glass mould and manufacturing method thereof

A technology for a glass mold and a manufacturing method, which is applied to a low-nickel high-iron copper alloy glass mold, and the manufacturing field of the above-mentioned glass mold can solve the problems of reduced service life of the mold, large temperature drop gradient, and high cost, and achieves long service life and good resistance. Oxidation, toughness enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

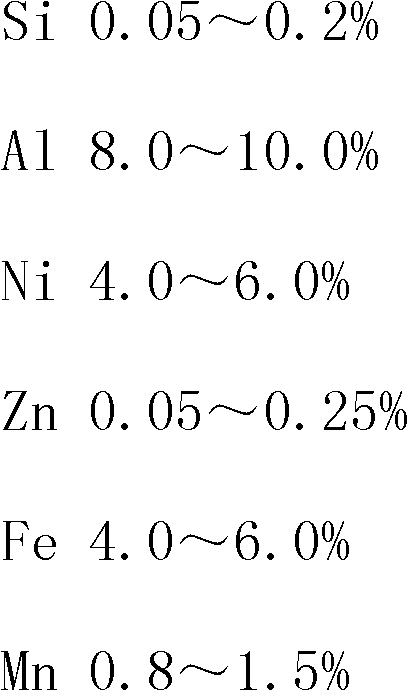

[0025] 1) The following weight percentage components are smelted:

[0026]

[0027] The rest is Gu and the usual impurities;

[0028] 2) Pouring at 1280°C;

[0029] 3) The holding time during heat treatment is 6 hours, and the temperature is controlled at 680°C;

[0030] 4) As the furnace temperature drops to 150°C, raise the furnace to room temperature and take it out.

[0031] The tensile strength of the obtained glass mold is 410N / mm 2 , Brinell hardness is 200, bending strength is 350N / mm 2 , the thermal conductivity is 0.12k / M.S.℃, and the coefficient of thermal expansion is 17*10 -6 m / k, the tested service life is 1.3 million times.

Embodiment 2

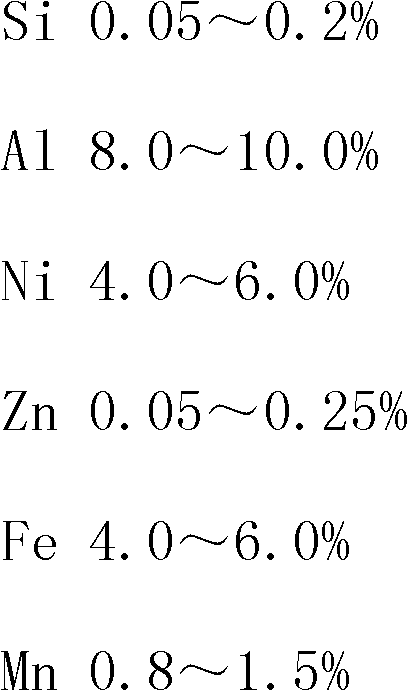

[0033] 1) The following weight percentage components are smelted:

[0034]

[0035] The rest is Gu and the usual impurities;

[0036] 2) Pouring at 1250°C;

[0037] 3) The holding time during heat treatment is 6 hours, and the temperature is controlled at 680°C;

[0038] 4) As the furnace temperature drops to 150°C, raise the furnace to room temperature and take it out.

[0039] The tensile strength of the obtained glass mold is 400N / mm 2 , Brinell hardness is 185, bending strength is 350N / mm 2 , the thermal conductivity is 0.15k / M.S.℃, and the coefficient of thermal expansion is 17*10 -6 m / k, the tested service life is 1.45 million times.

Embodiment 3

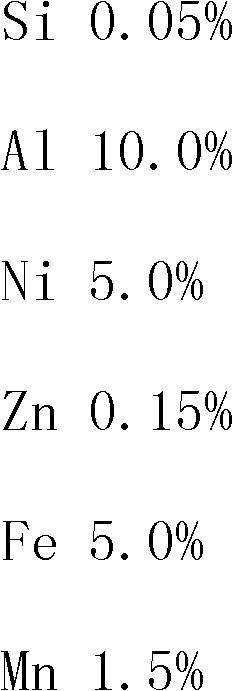

[0041] 1) The following weight percentage components are smelted:

[0042]

[0043] The rest is Gu and the usual impurities;

[0044] 2) Pouring at 1250°C;

[0045] 3) The holding time during heat treatment is 6 hours, and the temperature is controlled at 680°C;

[0046] 4) As the furnace temperature drops to 150°C, raise the furnace to room temperature and take it out.

[0047] The tensile strength of the obtained glass mold is 450N / mm 2 , Brinell hardness is 175, bending strength is 350N / mm 2 , the thermal conductivity is 0.13k / M.S.℃, and the coefficient of thermal expansion is 17*10 -6 m / k, the tested service life is 1.5 million times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com