Chicken feed prepared by fermenting processing residues of schisandra chinensis and preparation method of chicken feed

A technology for processing residues and chicken feed, applied in animal feed, animal feed, food processing, etc., can solve problems such as inability to guarantee feed intake and feed intake speed, low enzyme production effect and total number of viable bacteria, and increased feed cost , to achieve the effect of increasing feed intake and feed utilization rate, reducing feed and breeding costs, and improving immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

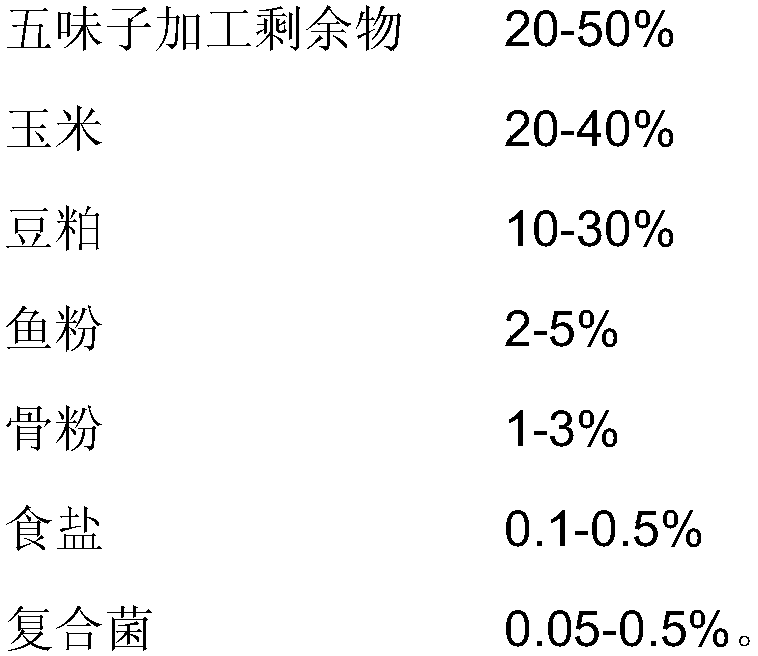

[0034] In the present embodiment, the ratio of raw materials and composite bacteria according to weight percentage is:

[0035]

[0036] Wherein the above-mentioned composite bacteria are composed by weight percentage:

[0037] Bacillus subtilis 40%, Lactobacillus plantarum 30%, Saccharomyces cerevisiae 30%.

[0038] The specific preparation process is:

[0039] (1) Crush the corn and soybean meal for later use.

[0040] (2) Mix all the crushed raw materials with different ratios of raw materials and composite bacteria evenly, add water to control the water content to 35%, put it into a plastic bag with an exhaust valve and seal it, and then ferment in a fermentation room at 30°C for 2 days.

[0041] (3) Transfer the fermented feed from the fermentation room to room temperature for preservation.

Embodiment 2

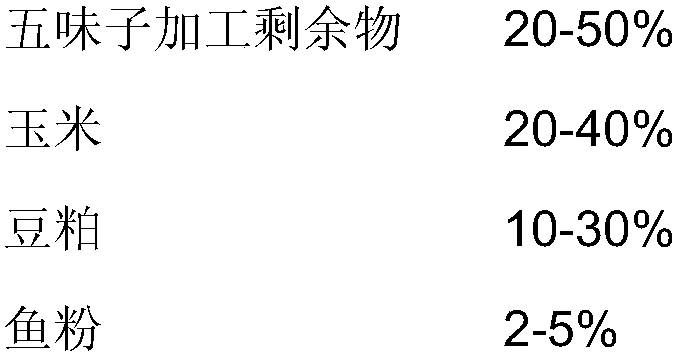

[0043] In the present embodiment, the ratio of raw materials and composite bacteria according to weight percentage is:

[0044]

[0045] Wherein the above-mentioned composite bacteria are composed by weight percentage:

[0046] Bacillus subtilis 50%, Lactobacillus plantarum 20%, Saccharomyces cerevisiae 30%.

[0047] The specific preparation process is:

[0048] (1) Crush the corn and soybean meal for later use.

[0049] (2) Mix all the crushed raw materials with different proportions of raw materials and composite bacteria evenly, add water to control the water content to 40%, put it into a plastic bag with an exhaust valve and seal it, and then ferment for 3 days in a fermentation room at 28°C.

[0050] (3) Transfer the fermented feed from the fermentation room to room temperature for storage.

Embodiment 3

[0052] This example is a verification example. In this example, the chicken feed (experimental group) prepared in Example 2 and the common chicken feed purchased in the market are entrusted to the Animal Husbandry Research Institute of Shanghai Academy of Agricultural Sciences to do a comparative experiment. The experimental location is Zhelin Breeding in Fengxian, Shanghai In the base, AA broilers were used for measurement, and the feed-to-meat ratio, antioxidant and oxidation indicators were measured. The specific experimental results are shown in Table 1 and Table 2.

[0053] Table 1 Production data on AA broilers

[0054]

[0055]It can be clearly known by the production data in Table 1 that the chicken feed of the present invention is far superior to the chicken feed of the control group in average weight gain and feed-to-meat ratio, wherein the feed-to-meat ratio is reduced by 8.78%, and the effect is very remarkable.

[0056] Table 2 The influence of serum antioxidan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com