Separator for lithium secondary battery and lithium secondary battery including the same

A technology for secondary batteries and separators, applied in secondary batteries, secondary battery parts, battery electrodes, etc., can solve the problems of the separator holes being not easy to close, low performance, easy to tear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1~6

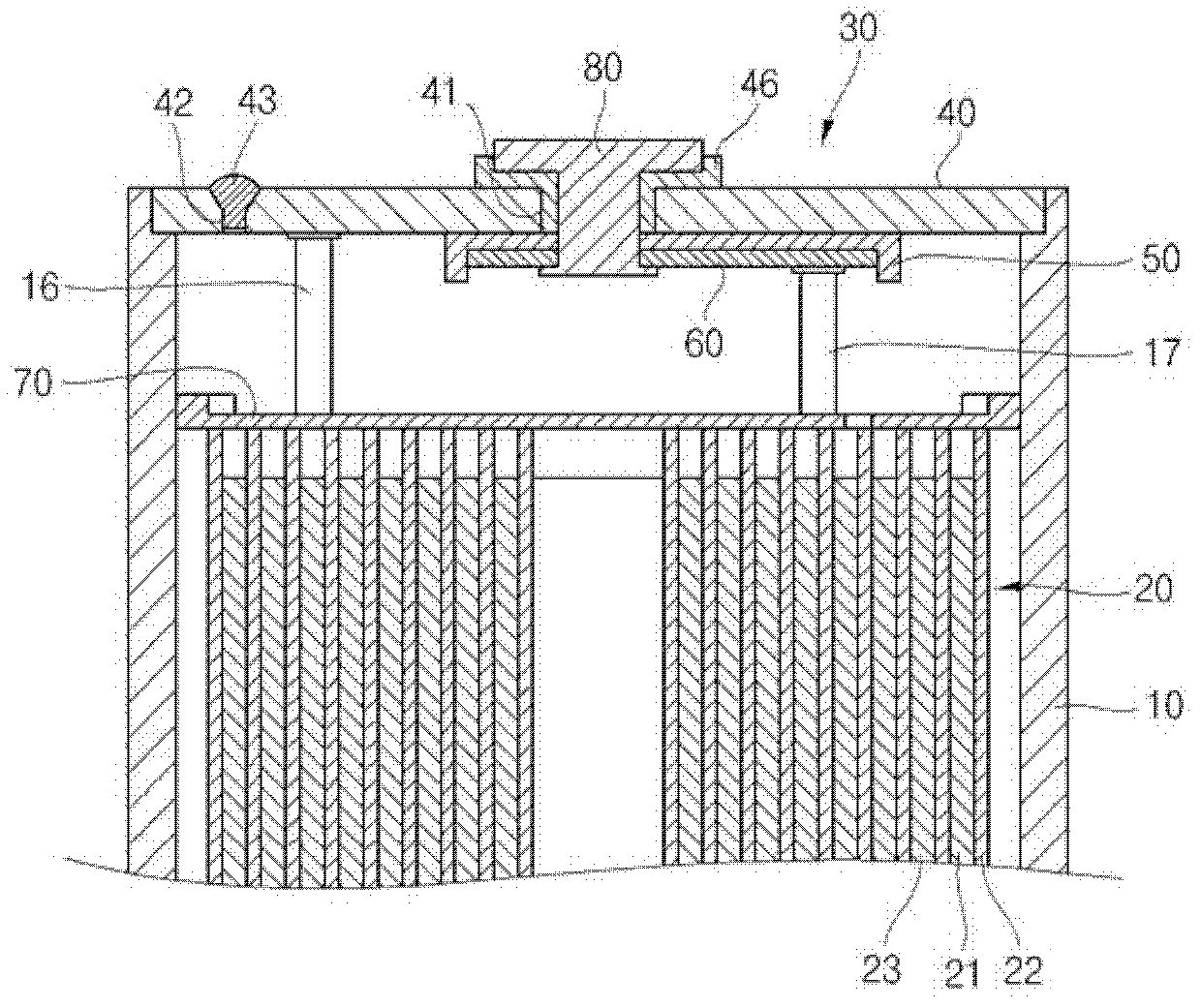

[0063] By using LiCoO as the cathode active material 2 , polyvinylidene fluoride (PVdF) as a binder, and carbon as a conductive material were dispersed in N-methyl-2-pyrrolidone solvent at a weight ratio of 92:4:4 to prepare a positive electrode active material slurry. A positive electrode plate was produced by coating the positive electrode active material slurry on an aluminum foil having a thickness of 15 μm, drying the positive electrode active material slurry coated on the aluminum foil, and drying the dried positive electrode active material slurry coated on the aluminum foil. The positive electrode active material slurry is rolled.

[0064] Negative electrode active material slurry was prepared as follows: Graphite as the negative electrode active material, styrene-butadiene rubber (SBR) as the binder and carboxymethyl cellulose (CMC) as the thickener were mixed in a weight ratio of 96:2:2 mixed and then dispersed in water. The negative electrode plate was manufacture...

experiment Embodiment 1

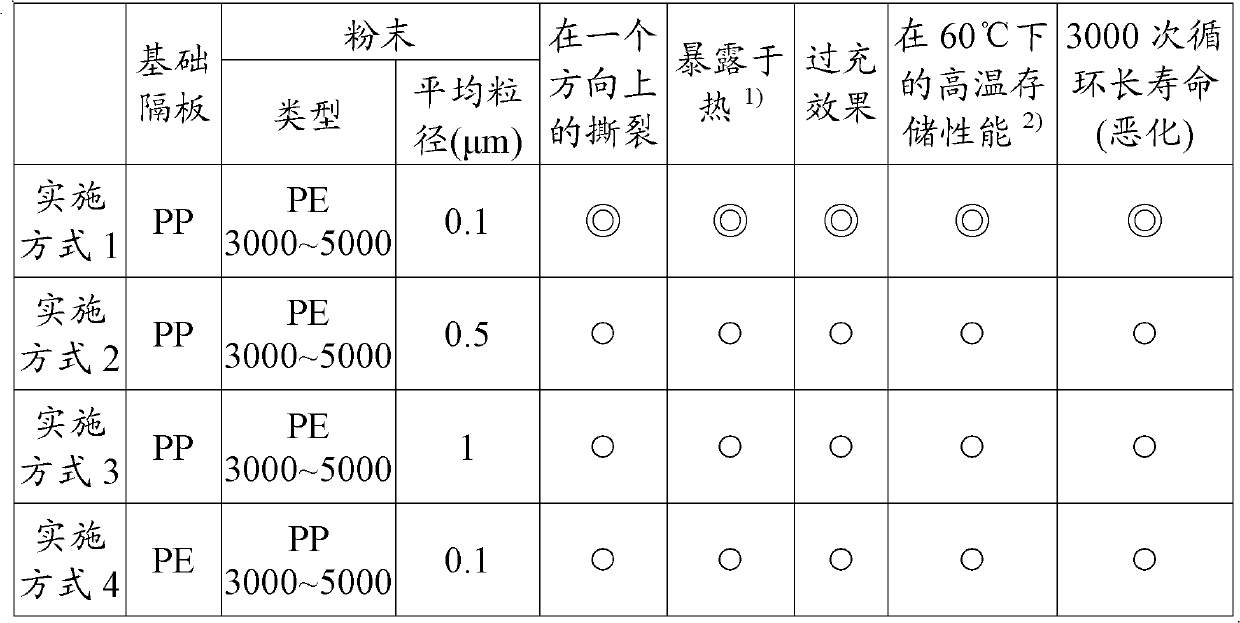

[0071] Experimental Example 1: Tear in one direction

[0072] TD tensile strengths of the separators prepared according to the embodiment and the comparative example were measured and shown in Table 1 according to the following standards.

[0073] ◎: 1000kgf / cm 2 ≤TD

[0074] ○: 750kgf / cm 2 ≤TD2

[0075] △: 500kgf / cm 2 ≤TD2

[0076] X: TD2

experiment Embodiment 2

[0077] Experimental Example 2: Safety Evaluation

[0078] With respect to the lithium secondary batteries manufactured according to the embodiment and the comparative example, short circuits were evaluated after exposing them to 150° C. for 10 minutes.

[0079] After the lithium secondary batteries manufactured according to the embodiment and the comparative example were charged at a rate of 3c up to 10V, states of the batteries were observed.

[0080] One of the following symbols is indicated depending on the battery status:

[0081] ◎: leaked

[0082] ○: Smoking, <200°C

[0083] △: Smoke, >200℃

[0084] X: Fire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com