Polyoxometallate/resin hybrid material capable of realizing photocatalytic degradation of organic dyes

A polyoxometalate, photocatalytic material technology, applied in chemical/physical processes, light water/sewage treatment, physical/chemical process catalysts, etc., to achieve good degradation, high photocatalytic activity, and easy separation and recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: K 7 [BW 11 o 39 Mn(H 2 O)] / en / Merrifield resin hybrid material preparation

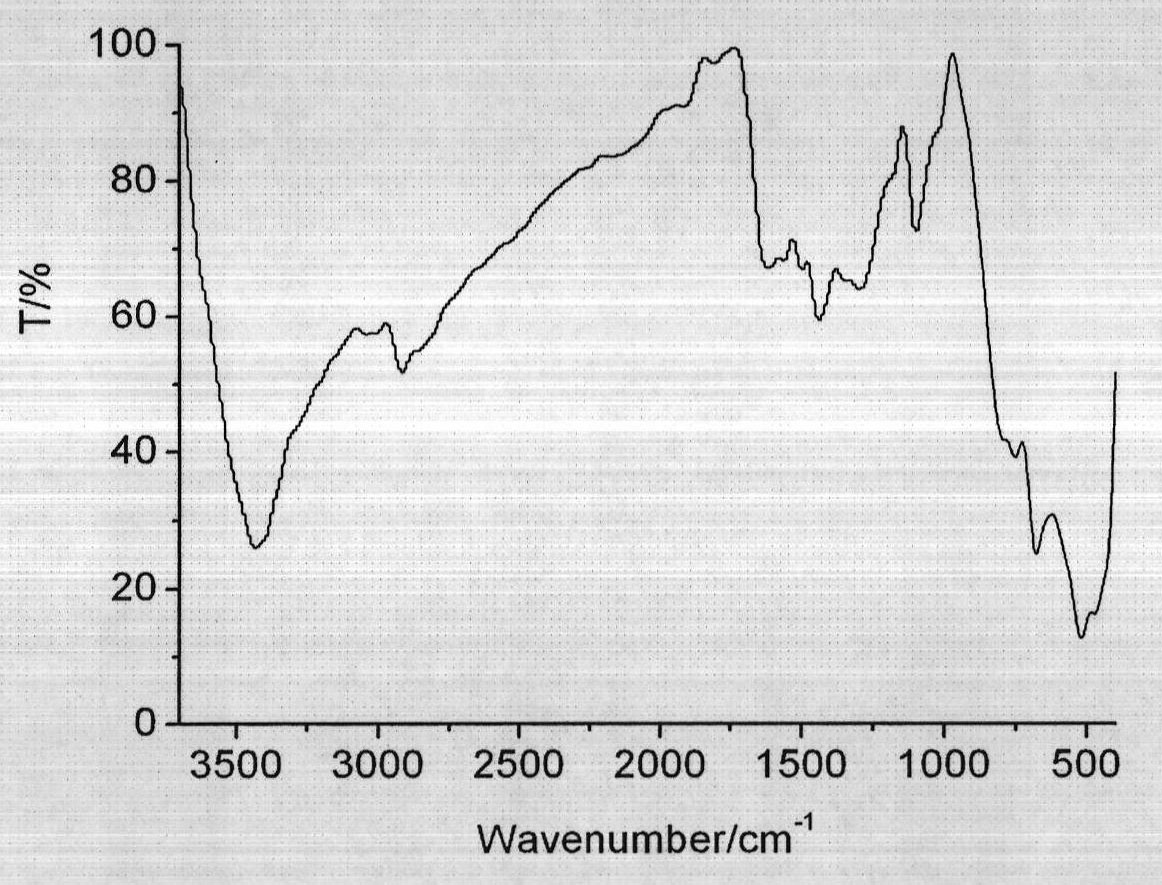

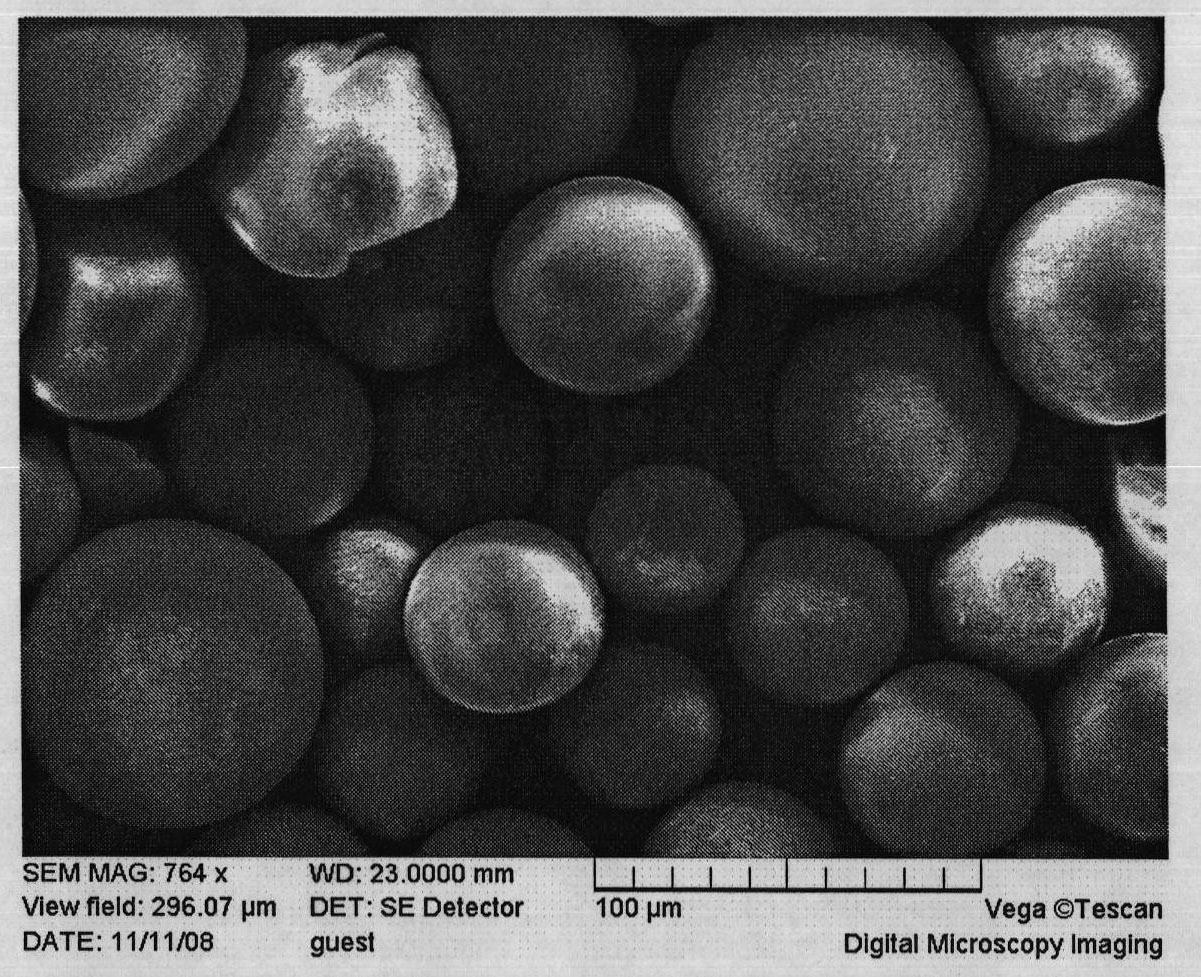

[0016] First, weigh 4.000g of resin and soak in 20mL of dioxane solvent for 36h, then add 10ml of ethylenediamine, heat to reflux for 10h, cool, filter, wash with water until the washing liquid is neutral, and dry in vacuum to obtain ethylenediamine-modified resin. Weigh 1.250 g of ethylenediamine-modified resin and disperse it in polyoxometalate K 7 [BW 11 o 39 Mn(H 2 O)] in aqueous solution (0.125gK 7 [BW 11 o 39 Mn(H 2 O)] dissolved in 25ml water), control the pH of the solution between 6 and 7, filter after stirring at room temperature for 24h, wash several times with distilled water at 80°C, and dry at room temperature to obtain K 7 [BW 11 o 39 Mn(H 2 O)] / en / Merrifield resin hybrid material. Its IR and SEM are shown in the attached figure 1 and 2 .

Embodiment 2

[0017] Example 2: K 7 [BW 11 o 39 Zn(H 2 O)] / en / Merrifield resin hybrid material preparation

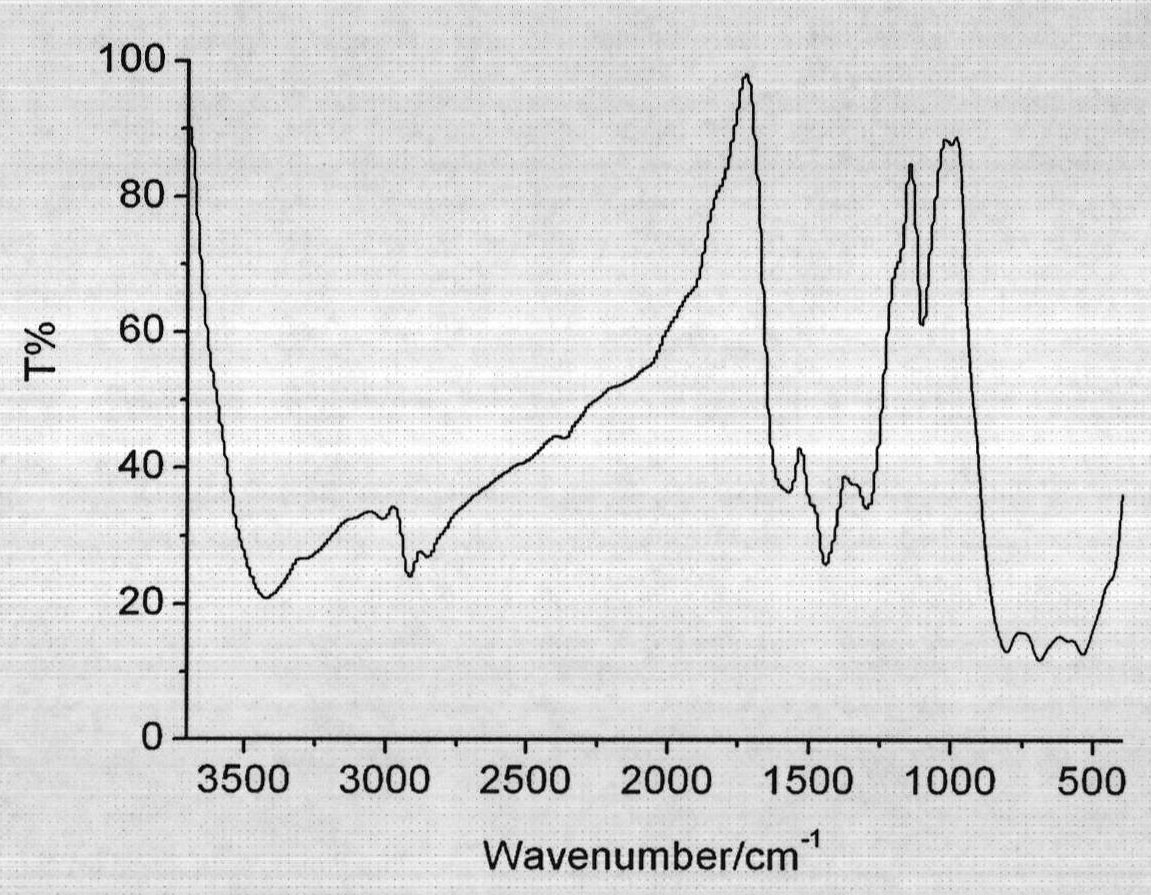

[0018] Synthesis steps and testing steps refer to Example 1. Among them, the polyoxometalate uses K 7 [BW 11 o 39 Zn(H 2 O)]. Its IR and SEM are shown in the attached image 3 and 4 .

Embodiment 3

[0019] Example 3: K 7 [BW 11 o 39 Cd(H 2 O)] / en / Merrifield resin hybrid material preparation

[0020] Synthesis steps and testing steps refer to Example 1. Among them, the polyoxometalate uses K 7 [BW 11 o 39 Cd(H 2 O)]. Its IR and SEM are shown in the attached Figure 5 and 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com