Complete equipment for preparing intermediate phase carbon microball as well as catalyst pretreatment device and preparation method

A technology of mesophase carbon microspheres and pretreatment devices, which is applied in the direction of carbon preparation/purification, can solve problems such as uneven mixing, long addition time, and intense catalytic reactions, so as to reduce production costs, improve production efficiency, and prevent Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

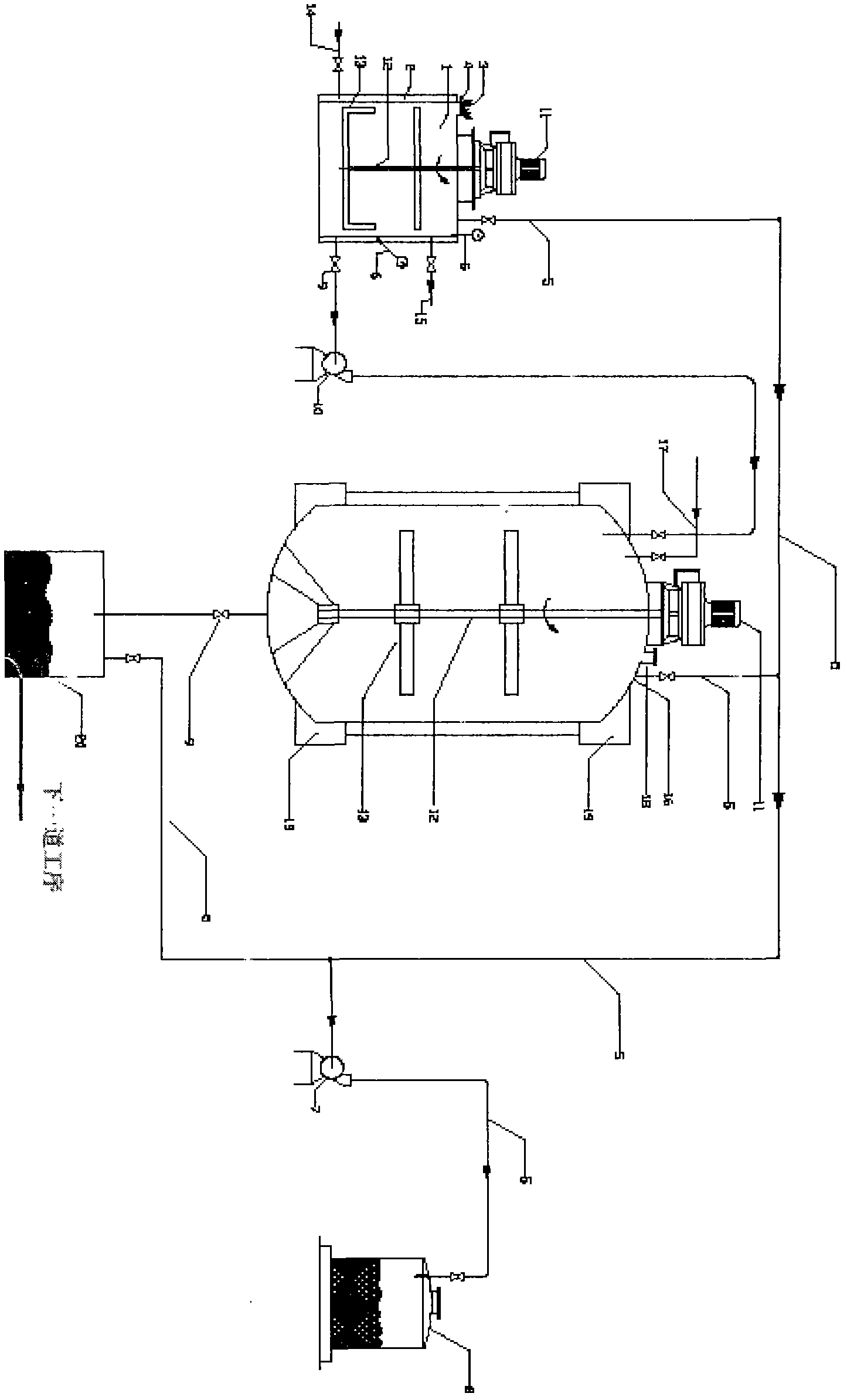

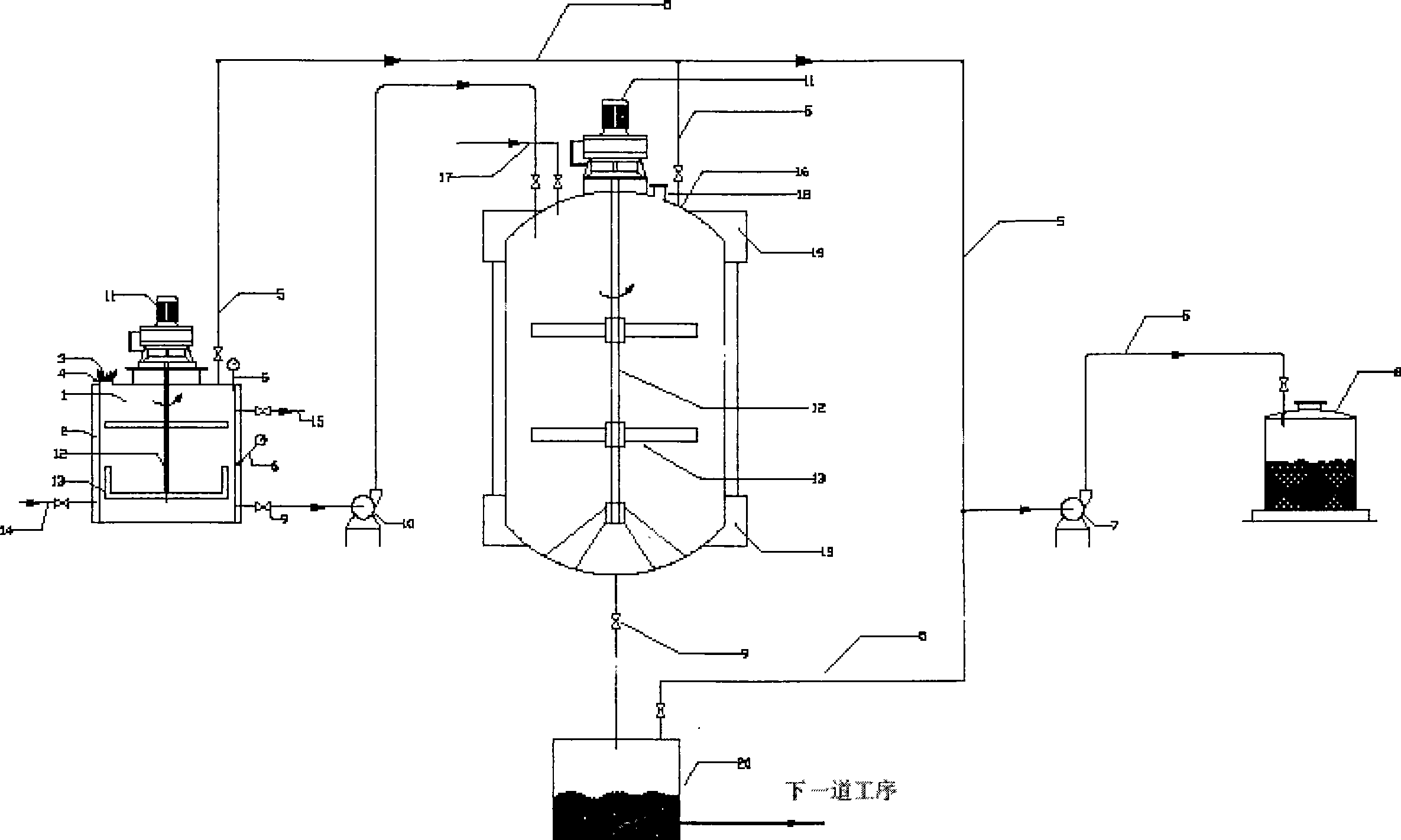

Method used

Image

Examples

Embodiment 1

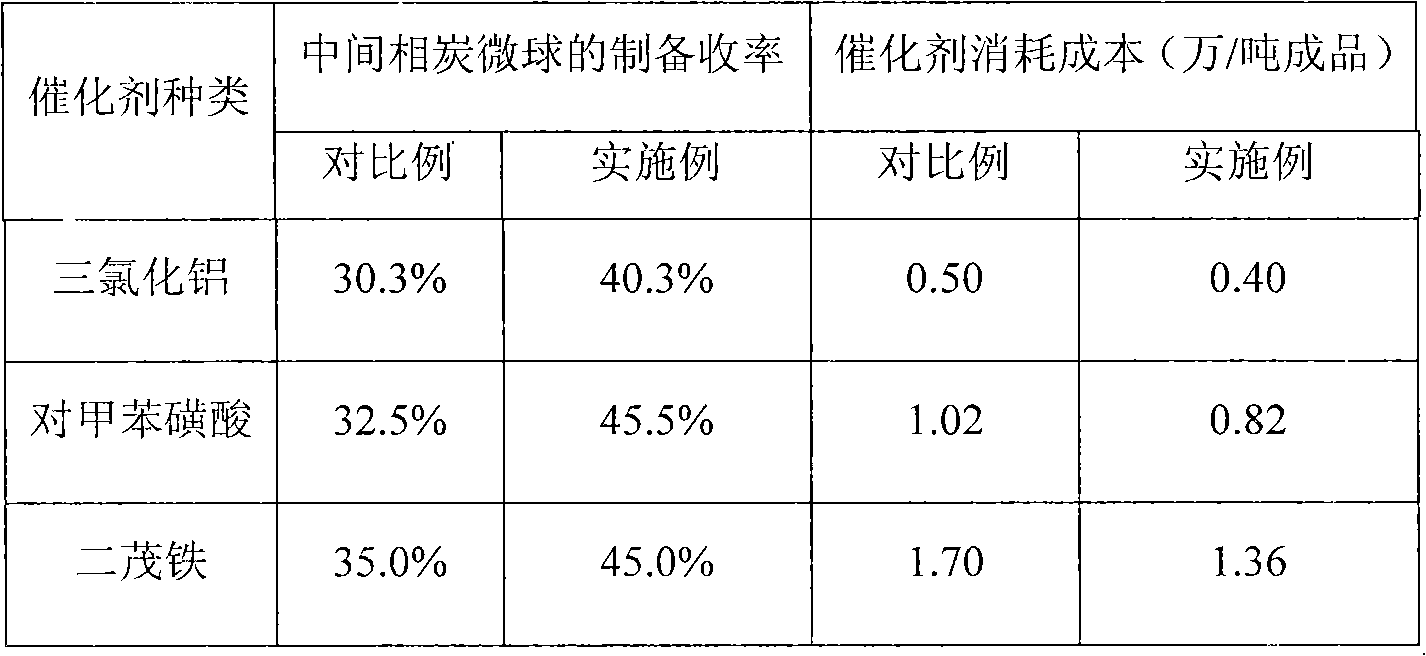

[0030] Example 1 Pretreatment Effect of Catalyst Aluminum Trichloride

[0031] 1) Open the feeding butterfly valve of the catalyst pretreatment device, add the catalyst aluminum trichloride from the feeding bin, add hot water from the water inlet of the jacket, open the water outlet of the jacket, keep the heating temperature of the water bath at 50-100°C, and wait for the catalyst to heat and melt After mixing evenly, inject the pretreated aluminum trichloride into the reaction kettle through the metering system, make it evenly mixed with the asphalt, and carry out thermal polycondensation reaction to prepare mesophase carbon microspheres.

[0032] 2) Comparative example: put 80-100 kg of catalyst aluminum trichloride directly into the reaction kettle, mix it with asphalt for thermal condensation reaction, and prepare mesophase carbon microspheres.

[0033] The preparation yield of mesophase carbon microspheres, catalyst consumption cost (10,000 / ton of finished product) and...

Embodiment 2

[0034] Example 2 Pretreatment Effect of Catalyst Ferrocene

[0035] 1) Open the feeding butterfly valve of the catalyst pretreatment device, add the catalyst ferrocene from the feeding bin, add hot water from the water inlet of the jacket, open the water outlet of the jacket, keep the heating temperature of the water bath at 50-100°C, wait for the catalyst to heat and melt and mix After uniformity, the pretreated aluminum trichloride is poured into the reaction kettle through the metering system, so that it is uniformly mixed with the asphalt, and the thermal polycondensation reaction is carried out to prepare the mesophase carbon microspheres.

[0036] 2) Comparative example: put 80-100 kg of catalyst ferrocene directly into the reactor, mix it with asphalt for thermal polycondensation reaction, and prepare mesophase carbon microspheres.

[0037] The preparation yield of mesophase carbon microspheres, catalyst consumption cost (10,000 / ton of finished product) and other aspe...

Embodiment 3

[0038] Example 3 Pretreatment Effect of Catalyst on Toluenesulfonic Acid

[0039] 1) Open the feeding butterfly valve of the catalyst pretreatment device, add the catalyst p-toluenesulfonic acid from the feeding bin, add hot water from the water inlet of the jacket, open the water outlet of the jacket, keep the heating temperature of the water bath at 50-100°C, and wait for the catalyst to heat and melt After mixing evenly, the pretreated aluminum trichloride is poured into the reactor through the metering system, so that it is uniformly mixed with the asphalt, and the thermal polycondensation reaction is carried out to prepare the mesophase carbon microspheres.

[0040] 2) Comparative example: put 80-100 kg of catalyst p-toluenesulfonic acid directly into the thermal polycondensation reaction kettle, mix it with asphalt for thermal polycondensation reaction, and prepare mesophase carbon microspheres.

[0041] The preparation yield of mesophase carbon microspheres, catalyst ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com