Catalytic conversion technology for carbon tetrachloride

A carbon tetrachloride and catalytic conversion technology, applied in the chemical industry, can solve the problems of atmospheric ozone layer hazards, high oxygen consumption index, long reaction time, etc., and achieve the effects of reducing production costs, increasing reaction speed, and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

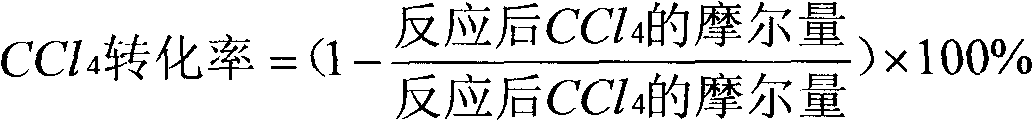

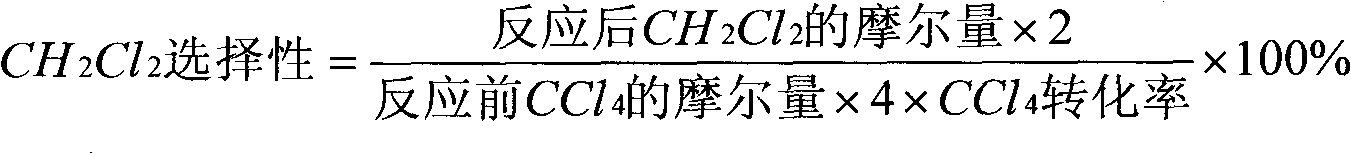

Method used

Image

Examples

Embodiment 1

[0032] In a stainless steel autoclave, 0.3 g of self-made 12% AgCl / AC (AC is the abbreviation of activated carbon, the same below) catalyst was added, 5 ml of carbon tetrachloride, 23 ml of methanol, and 2 ml of 40% acetaldehyde were added. Close the reactor, replace the air in the reactor with nitrogen for three times, then feed nitrogen and maintain the pressure in the reactor, raise the temperature to 130°C, the reaction pressure is 4.0MPa, start stirring, react at constant temperature for 5 hours, and analyze the product with gas chromatography The results are shown in Table 1.

Embodiment 2

[0034] In a stainless steel autoclave, add 0.3 g of 8% Ag / AC catalyst, 5 ml of carbon tetrachloride, 15 ml of methanol, and 10 ml of hydrazine hydrate. Close the reactor, replace the air in the reactor with nitrogen for three times, then feed nitrogen and maintain the pressure in the reactor, raise the temperature to 200°C, the reaction pressure is 1.0MPa, start stirring, react at constant temperature for 5 hours, and analyze the product by gas chromatography The results are shown in Table 1.

Embodiment 3

[0036] In a stainless steel autoclave, add 0.3g of self-made 8%Ag-0.01%Pd / AC catalyst, add 5ml of carbon tetrachloride, 20ml of methanol, and 5ml of hydrazine hydrate. Close the reactor, replace the air in the reactor with nitrogen for three times, then feed nitrogen and maintain the pressure in the reactor, raise the temperature to 130°C, the reaction pressure is 1.0MPa, start stirring, react at constant temperature for 3 hours, and analyze the product by gas chromatography The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com