Treating method and system for crude methylthiopropanal synthesized of methyl mercaptan and acraldehyde

A technology of methylthiopropionaldehyde and acrolein, applied in chemical instruments and methods, preparation of organic compounds, preparation of sulfide, etc., can solve problems such as environmental pollution, affecting continuous and stable production in workshops, and leakage of heavy components , to achieve the effect of improving the residents' environment and eliminating environmental incidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

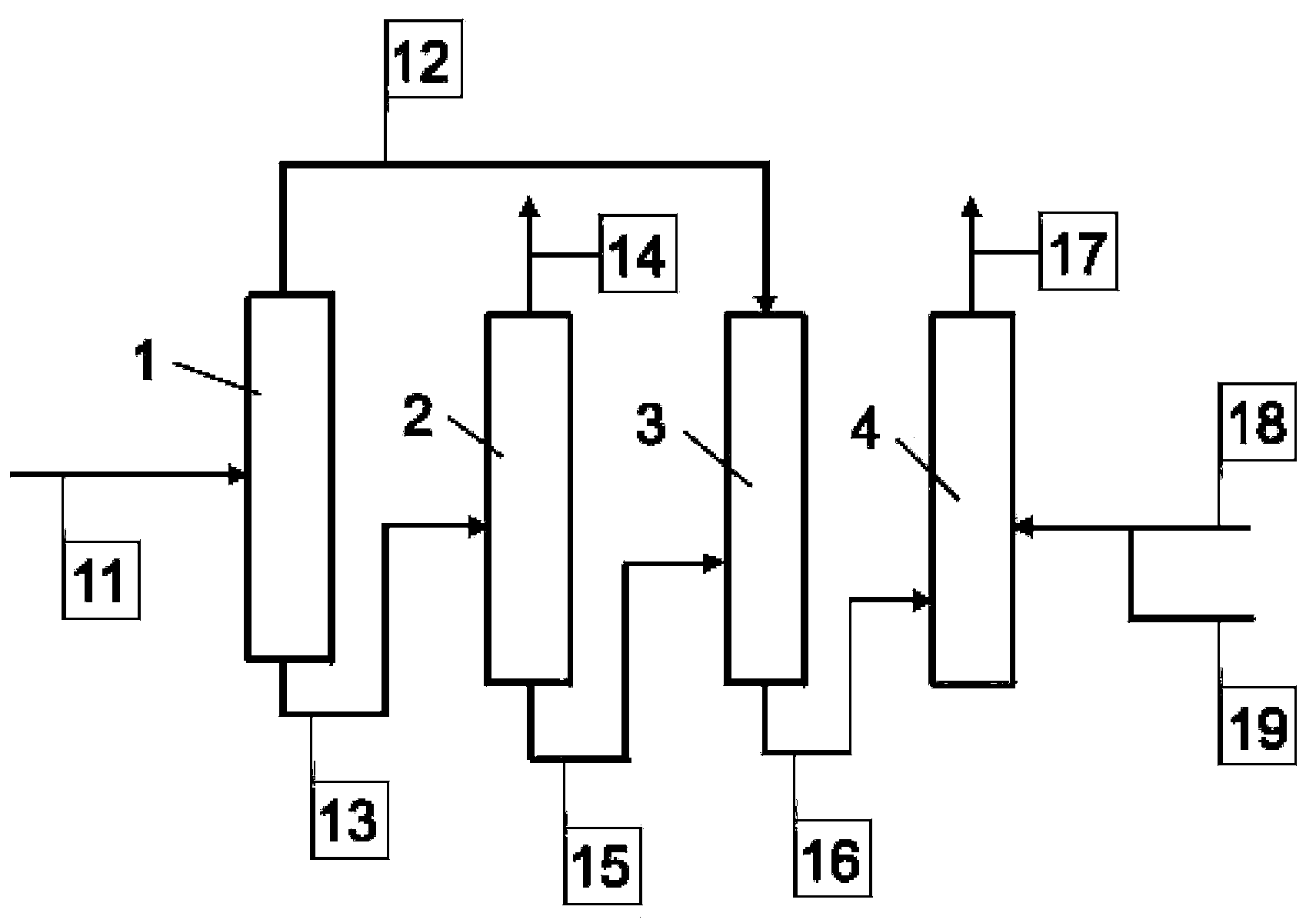

[0026] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] see figure 1 An exemplary process flow diagram for the treatment of crude methionaldehyde synthesized from the reaction of methyl mercaptan and acrolein. Crude methylthiopropionaldehyde11, mainly including methylthiopropionaldehyde, hydrogen sulfide, methyl sulfide, acrolein, acetic acid, methanol, water, hydroquinone, morpholine, acrolein polymer and methylthio Propionaldehyde polymer, etc. Crude methylthiopropionaldehyde 11 is continuously sent into the low-vacuum rectification tower 1 through the pump, and the vacuum degree is 8-20 kPa, preferably under the low-vacuum condition of 15-18 kPa, the boiling point is lower than that of methylthiopropionaldehyde. The light components 12 of propionaldehyde, including hydrogen sulfide, methyl sulfide, acrolein, acetic acid, methanol, morpholine and water, are discharged fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com