Method and device for preventing yellow phosphorus furnace gas conveying pipeline from being blocked and removing dust

A yellow phosphorus furnace gas and pipeline technology is applied in the field of preventing the blockage of the yellow phosphorus furnace gas pipeline and dust removal, which can solve the problems of blocked pipelines, high equipment maintenance rate, difficult pipeline transportation, etc., so as to reduce energy consumption and parts damage rate. The effect of increasing the contact area and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

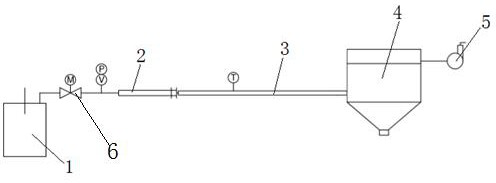

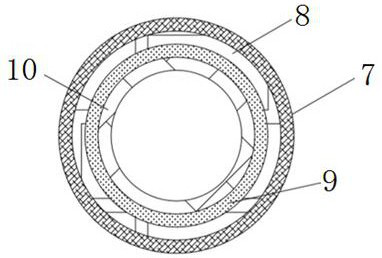

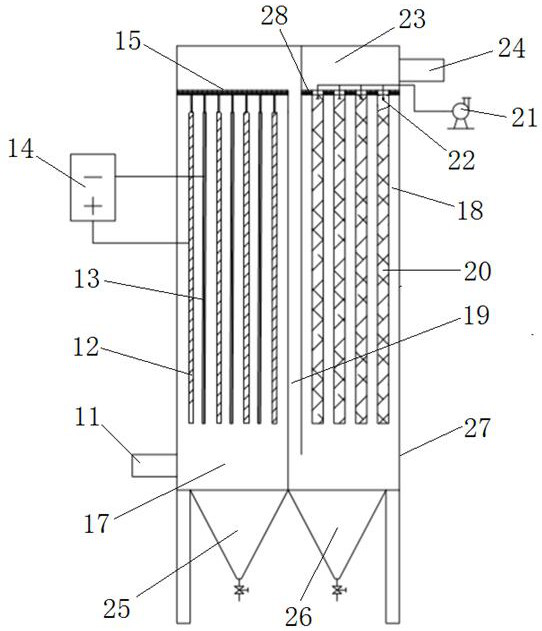

[0029] Embodiment 1: as Figure 1-4 As shown, the device for preventing the blockage and dust removal of the yellow phosphorus furnace gas pipeline includes a yellow phosphorus electric furnace 1, a heater 2, a multi-layer structure coupled insulation pipe 3, an electric bag dust collector 4, and a fan 5. The yellow phosphorus electric furnace 1 passes through the pipeline It communicates with the heater 2 and the pipeline is equipped with an electric valve 6, a pressure gauge, and a flow meter. The heater 2 communicates with the electric bag filter 4 through a multi-layer structure coupled insulation pipe 3, and the fan 5 is connected with the electric bag filter 4; The thermal insulation pipe 3 coupled with a multi-layer structure includes a protective layer 7, a thermal insulation layer 8, a heating layer 9, and a heat transfer layer 10; the heating layer 10 is arranged between the thermal insulation layer and the heat transfer layer, and the protective layer is set outside ...

Embodiment 2

[0032] Embodiment 2: The device structure of this embodiment is the same as that of Embodiment 1, the difference is that the cloth bag is made of high temperature resistant ordinary filter cloth, the material is polytetrafluoroethylene, the cathode wire is arranged in the frame, and the cathode wire is a zigzag cathode wire; the anode It is a plate-shaped alloy steel electrode, the cathode wire is a zigzag nickel-chromium alloy wire, and the bag is a hollow cuboid with an open top;

[0033] Yellow phosphorus furnace gas is produced during the production of yellow phosphorus by electric furnace method in a yellow phosphorus factory, with a flow rate of 2000m 3 / h, the temperature is about 190°C, the yellow phosphorus furnace gas enters the heater directly from the pipeline for heating, and the temperature rises to about 250°C, after heating, the yellow phosphorus furnace gas is transported to the electric bag filter through the multi-layer structure coupled insulation pipe , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com