Method for preparing high-purity matrine from sophora alopecuroides

A technology for matrine and Sophora fragrans, which is applied in the field of preparing high-purity matrine, can solve the problems of not producing an ideal effect, the separation technology is not ideal, mature, and the content of matrine is not increased, and achieves strong industrial practicability. , to avoid partial loss, the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

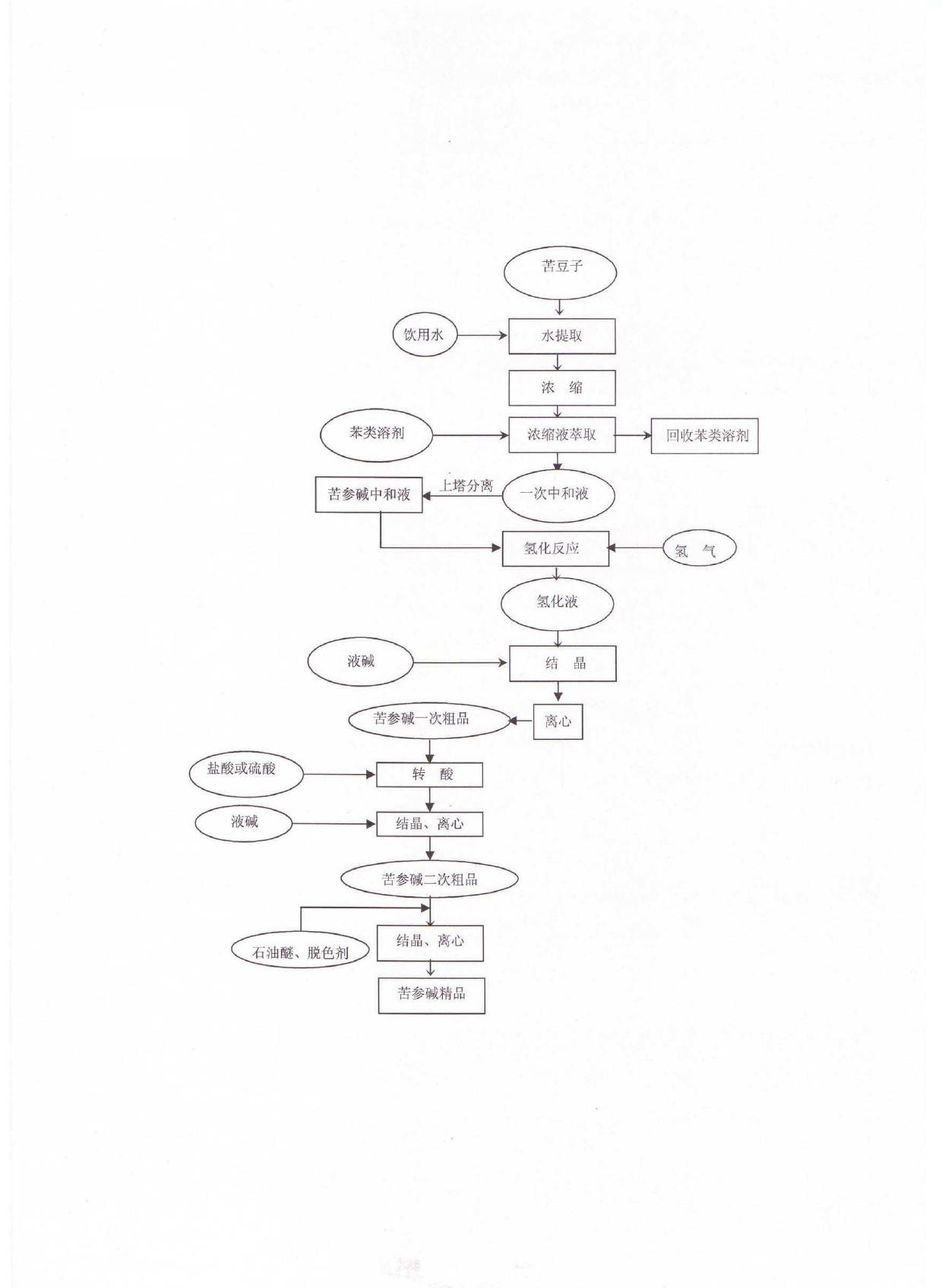

Image

Examples

Embodiment 1

[0027] (1) Put the bitter beans into the extraction tank, add water to pass through the steam, heat and extract, settle and filter;

[0028] (2) Concentrate the extract;

[0029] (3) Add caustic soda and sodium hydroxide to the concentrated solution to adjust the pH to 11-12, repeat the extraction several times with toluene, neutralize the extract with 10% hydrochloric acid to make the pH 4-5, and separate the neutralized liquid on the tower;

[0030] (4) Separate matrine neutralizing solution, add liquid caustic soda sodium hydroxide to adjust pH to 7-8, add aluminum-nickel alloy catalyst, pass hydrogen, heat until there is no sophocarpine and sophoramine in the neutralizing solution. Add liquid alkali and sodium hydroxide to the hydrogenation solution to adjust the pH to 11-12, let it stand still, and centrifuge to obtain a crude product of matrine;

[0031] (5) Add 5% HCL to the crude product of matrine to adjust the pH value to 5-6, let it sit for 2 hours and filter it in...

Embodiment 2

[0034] (1) Put the bitter beans into the extraction tank, add water to pass through the steam, heat and extract, settle and filter;

[0035] (2) Concentrate the extract;

[0036] (3) Add caustic soda and sodium hydroxide to the concentrated solution to adjust the pH to 11-12, repeat the extraction several times with toluene, neutralize the extract with 10% hydrochloric acid to make the pH 4-5, and separate the neutralized liquid on the tower;

[0037] (4) Separate matrine neutralizing solution, add liquid caustic soda sodium hydroxide to adjust pH to 7-8, add aluminum-nickel alloy catalyst, pass hydrogen, heat until there is no sophocarpine and sophoramine in the neutralizing solution. Add liquid alkali and sodium hydroxide to the hydrogenation solution to adjust the pH to 11-12, let it stand still, and centrifuge to obtain a crude product of matrine;

[0038] (5) Add distilled water to the primary crude product, then heat to dissolve, cool, and centrifugally dry to obtain th...

Embodiment 3

[0041] (1) Put the bitter beans into the extraction tank, add water to pass through the steam, heat and extract, settle and filter;

[0042] (2) Concentrate the extract;

[0043] (3) Add potassium hydroxide to the concentrated liquid to adjust the pH to 11-12, repeat the extraction with toluene several times, neutralize the extract with 10% hydrochloric acid to make the pH 4-5, and separate the neutralized liquid on the tower;

[0044] (4) Separate matrine neutralizing solution, add liquid caustic soda potassium hydroxide to adjust pH to 7-8, add aluminum-nickel alloy catalyst, pass hydrogen, heat until there is no sophocarpine and sophoramine in the neutralizing solution. Add liquid alkali potassium hydroxide to the hydrogenation solution to adjust the pH to 11-12, let it stand still, and centrifuge to obtain a crude product of matrine;

[0045] (5) Add 5% HCL to the crude product of matrine to adjust the pH value to 5-6, let it sit for 2 hours and filter it into the free cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com