High temperature-resistant ceramics coating for non-stick cookware, and preparation method thereof

A technology of high-temperature resistant ceramics and coatings, applied in the direction of coating, etc., can solve the problems of endangering human health, poor high-temperature resistance, and easy pollution of the environment, so as to improve the overall temperature resistance, strengthen heat resistance, and ensure high-temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

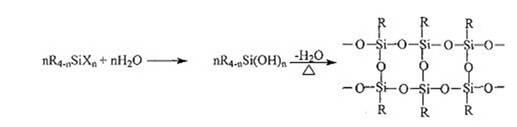

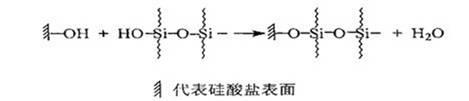

Method used

Image

Examples

Embodiment 1

[0023] 1) Mix 4 parts of isopropanol and 18 parts of deionized water, then add 1.5 parts of carboxymethyl cellulose acetate butyrate, and then add 46 parts of silica sol, 4 parts of alumina sol, and 2 parts of zirconia sol in sequence , 6 parts of mica powder, 1 part of iron oxide black, 2 parts of high-temperature alumina, stir evenly at 800rpm high speed, and then grind it with a grinder for 5 hours to a fineness ≤10μm, then add phosphoric acid solution to adjust the pH of the mixture=3.5, and finally Add 1.5 parts of fluorosilicone oil and stir evenly to obtain the A component of the coating.

[0024] 2) Mix 3 parts of isopropanol and 3 parts of ethanol, and add 62 parts of methyltriethoxysilane, 15 parts of dimethyldimethoxysilane, respectively in order under the condition of stirring at 20℃ and 100rpm at low speed. 8 parts of monophenyltriethoxysilane, stir and disperse uniformly to make paint B component.

[0025] 3) The A component obtained in step 1) and the B component ob...

Embodiment 2

[0027] 1) Mix 6 parts of isopropanol and 20 parts of deionized water, then add 2 parts of carboxymethyl cellulose acetate butyrate, and then add 48 parts of silica sol, 6 parts of alumina sol, and 3 parts of zirconia sol in sequence , 7.5 parts of mica powder, 2 parts of iron oxide black, 3 parts of high-temperature alumina, after stirring at 900rpm high speed, milling for 6 hours to fineness ≤10μm by grinder, then adding phosphoric acid solution to adjust the pH of the mixture=4, finally Add 3 parts of fluorosilicone oil and stir to obtain the A component of the coating.

[0028] 2) Mix 5 parts of isopropanol and 5 parts of ethanol, and add 65 parts of methyltriethoxysilane, 18 parts of dimethyldimethoxysilane, and 18 parts of dimethyldimethoxysilane in order under the condition of low speed stirring at 25℃ and 125rpm. 11 parts of monophenyltriethoxysilane, stir and disperse uniformly to make the coating B component.

[0029] 3) The A component obtained in step 1) and the B compo...

Embodiment 3

[0031] 1) Mix 8 parts of isopropanol and 23 parts of deionized water, then add 3 parts of carboxymethyl cellulose acetate butyrate, and then add 50 parts of silica sol, 8 parts of alumina sol, and 5 parts of zirconia sol in sequence , 9 parts of mica powder, 3 parts of iron oxide black, 5 parts of high-temperature alumina, stir evenly at 1000 rpm high speed, and then grind it with a grinder for 7 hours to fineness ≤ 10μm, then add phosphoric acid solution to adjust the pH of the mixture = 4.5, and finally Add 4.5 parts of fluorosilicone oil and stir evenly to obtain the A component of the coating.

[0032] 2) Mix 8 parts of isopropanol and 8 parts of ethanol, and add 68 parts of methyltriethoxysilane, 20 parts of dimethyldimethoxysilane, and 20 parts of dimethyldimethoxysilane in order under the condition of low speed stirring at 30℃ and 150rpm. 13 parts of a phenyltriethoxysilane, stir and disperse uniformly to make the coating B component.

[0033] 3) The A component obtained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com