Preparation method of self-heating food heating agent

A heating agent and food technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of affecting heating efficiency, long production cycle, and low heat output per unit, so as to simplify the production process, shorten the processing time, and unit The effect of high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

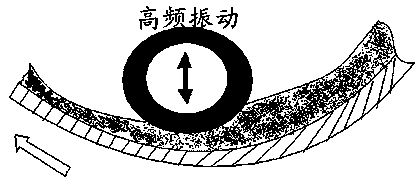

Method used

Image

Examples

Embodiment 1

[0020] The components and weight percentages of a self-heating food heating agent: 65% magnesium powder, 25% iron powder, and 10% surfactant.

[0021] Weigh the materials according to the proportion and pour them into the surface modification equipment. The equipment speed is set to 100 rpm and the processing time is 2 minutes to make the materials evenly mixed and dispersed. Inert gas is introduced into the surface modification equipment, the material heating device is turned on, the material temperature is raised to 60°C, the equipment speed is adjusted to 500 rpm, and the surface modification treatment is performed. The processing time is 5 minutes. Liquid nitrogen is introduced into the surface modification equipment for rapid cooling, and the material can be discharged after the temperature drops to room temperature.

[0022] Take 10 g of the food heating agent to conduct a heating test on 250 g of rice dumplings. The time required from adding the reaction water to heating of...

Embodiment 2

[0024] The components and weight percentages of a self-heating food heating agent: 75% magnesium powder, 20% iron powder, and 5% surfactant.

[0025] Weigh the materials according to the proportion and pour them into the surface modification equipment. The equipment speed is set to 100 rpm and the processing time is 2 minutes to make the materials evenly mixed and dispersed. Inert gas is introduced into the surface modification equipment, the material heating device is turned on, the material temperature is raised to 60-80°C, the equipment speed is adjusted to 500 rpm, and the surface modification treatment is performed. The processing time is 5 minutes. Liquid nitrogen is introduced into the surface modification equipment for rapid cooling, and the material can be discharged after the temperature drops to room temperature.

[0026] Take 10 g of the food heating agent to conduct a heating test on 250 g of rice dumplings. The time required from adding the reaction water to heating ...

Embodiment 3

[0028] The components and weight percentages of a self-heating food heating agent: 78% magnesium powder, 17% iron powder, and 5% surfactant.

[0029] Weigh the materials according to the proportion and pour them into the surface modification equipment. The equipment speed is set to 150 rpm and the processing time is 2 minutes to make the materials evenly mixed and dispersed. Inert gas is introduced into the surface modification equipment, the material heating device is turned on, the material temperature is increased to 60-80°C, the equipment speed is adjusted to 400 rpm, and the surface modification treatment is performed. The processing time is 5 minutes. Liquid nitrogen is introduced into the surface modification equipment for rapid cooling, and the material can be discharged after the temperature drops to room temperature.

[0030] Take 10 g of the food heating agent to conduct a heating test on 250 g of rice dumplings. The time required from adding the reaction water to heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com