Measuring method for construction depth of asphalt road surface

A technology for asphalt pavement and structural depth, which is applied in the field of measuring structural depth, can solve the problems of reducing the evaluation of pavement structural depth, large detection technology errors, and low efficiency, so as to reduce labor intensity, improve measurement efficiency, and ensure no superposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

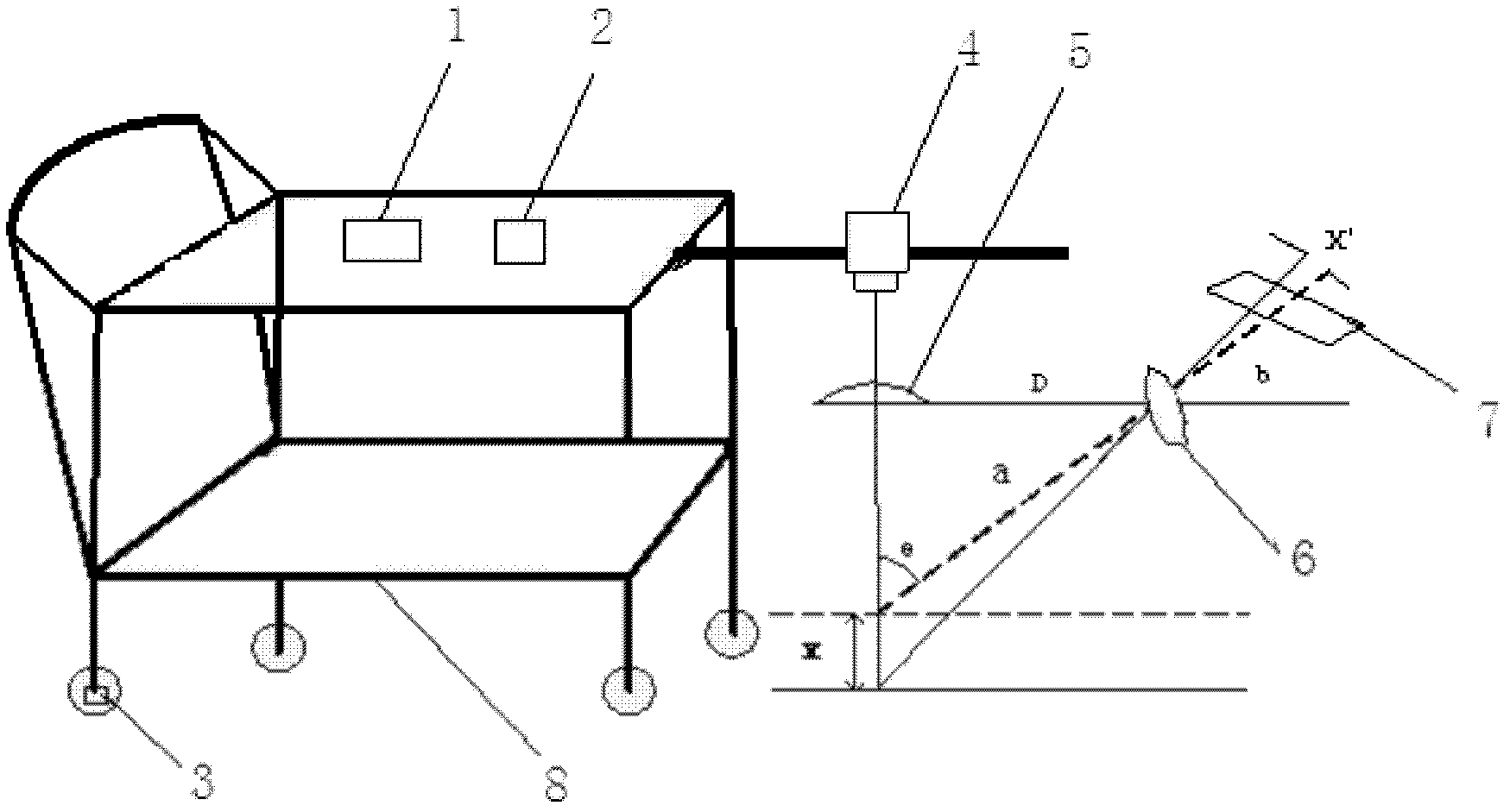

[0044] The CPU of computer 1 is RII350, the hard disk is 6.0GB, and the memory is 64MB. Encoder 3 adopts Omron E6B2-CWZ6C series encoder. The linear laser 4 is an infrared linear array laser, the CCD camera 7 is a CCD area array camera, and the CCD target surface is 1000*1000.

[0045] The infrared linear array laser has good light source characteristics. The laser beam emitted by the laser beam is relatively uniform and sensitive to infrared light. The spectral response is within the photosensitive area of the area array CCD camera. The effect of the pictures taken is relatively good. It is suitable for High-precision measurement and testing.

[0046] The encoder 3 is used to convert the displacement signal of the trolley 8 into an electrical signal and transmit it to the computer 1. The computer 1 sends the electrical signal to the CCD camera 6 in the form of a trigger through the built-in software control, so as to control the shooting frequency of the CCD camera 6. Tha...

Embodiment 2

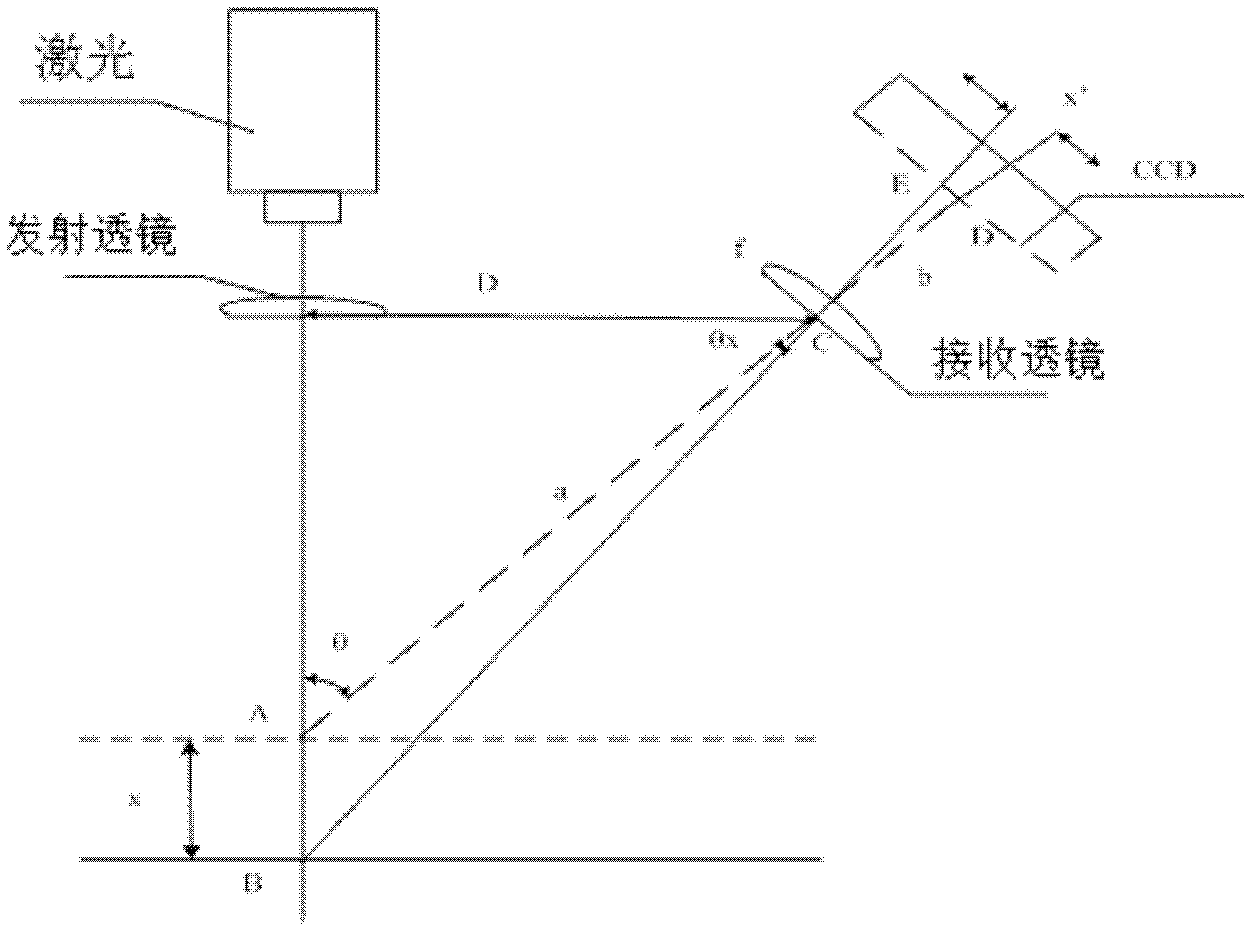

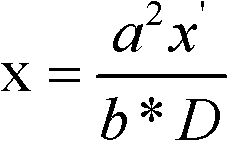

[0054] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the included angle θ is set to 35 degrees, a is 1221 mm, D is 700 mm, the height of the linear laser 4 is 1 meter, and the field of view is 1 meter. The depth of the asphalt pavement structure in the measured area is 0.5.186mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com