Fully-closed noise reduction structure of refrigeration compressor

A refrigeration compressor, fully enclosed technology, applied in the field of refrigeration compressors, can solve the problems of large noise, high energy excited by valve seat sound, and aggravated vibration of the shell, so as to reduce mechanical noise and reduce the effect of noise transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

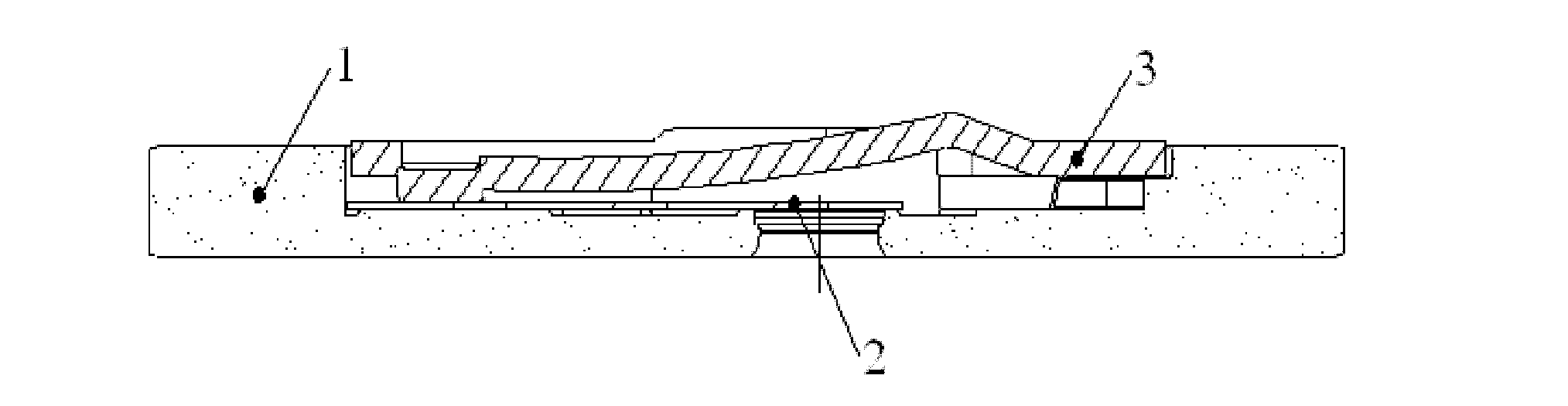

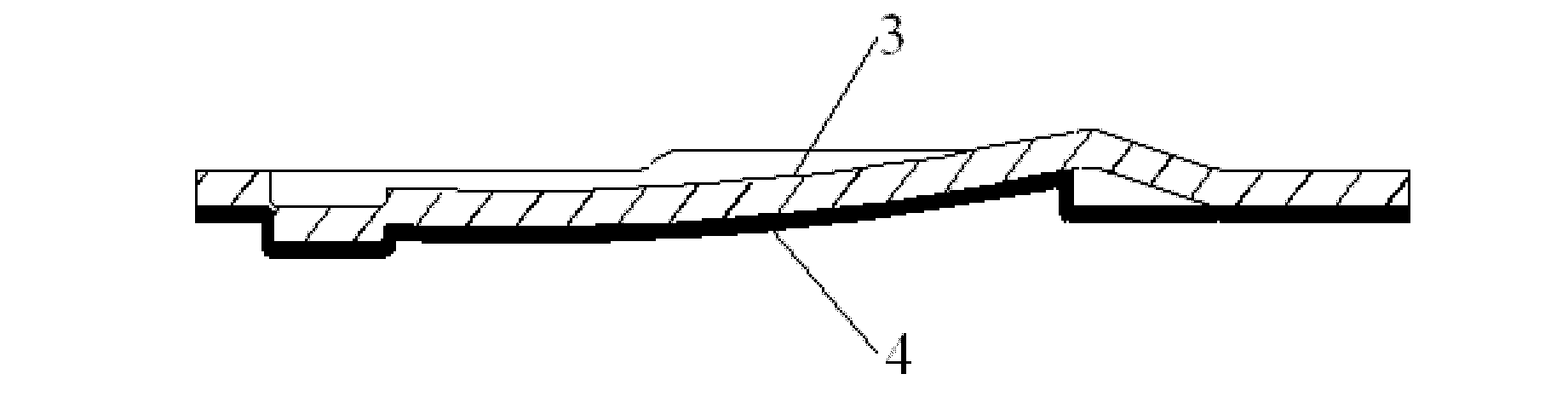

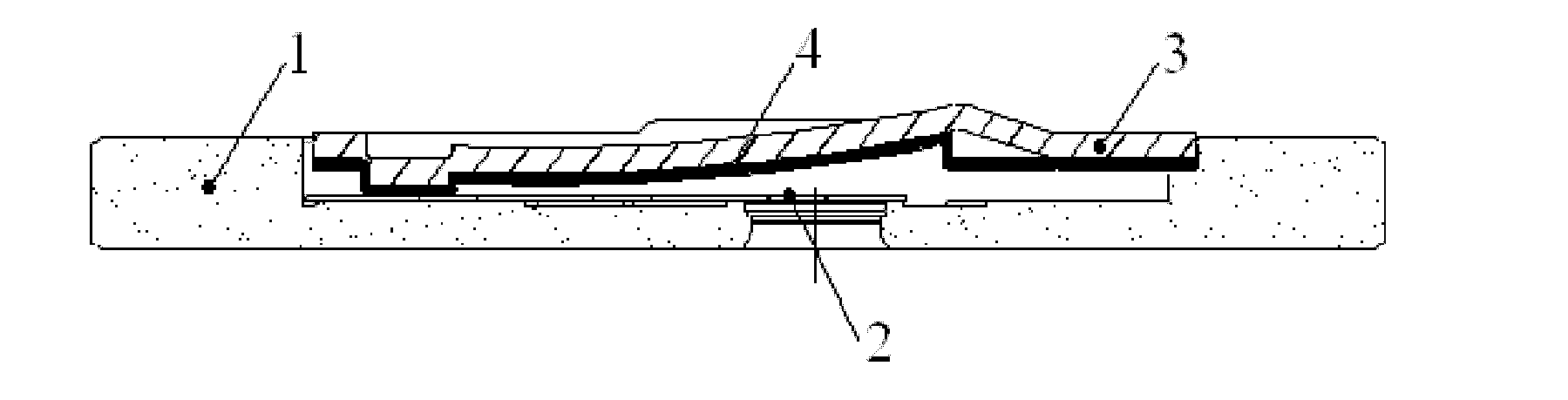

[0034] like figure 2 , image 3 As shown, the present invention provides a noise reduction structure for a fully enclosed refrigeration compressor. The refrigeration compressor is provided with an exhaust valve, including a valve plate 1, an exhaust valve plate 2 and an exhaust valve plate limiting plate. The exhaust valve plate limiting plate is a cold-rolled carbon steel limiting plate 3, and a damping material layer is provided on the surface of the exhaust valve plate 2 on the cold-rolled carbon steel limiting plate 3. .

[0035] The damping material layer is a sprayed damping layer 4, and the material composition of the sprayed damping layer 4 mainly includes polymer resin.

[0036] An epoxy primer is also mixed in the sprayed damping layer 4 .

[0037] In this embodiment, for the existing valve plate assembly, the rigid contact mode between the original exhaust limiting plate and the valve plate is changed, and a coating of damping material is added on the exhaust li...

Embodiment approach

[0038] The specific implementation method is:

[0039] Using polymer resin, adding appropriate amount of fillers and auxiliary materials to prepare damping paint coating materials, spraying damping paint directly on the side of the exhaust limit plate to limit the lift of the exhaust valve plate to form a sprayed damping layer 4 . Alternatively, the damping paint is used in conjunction with the epoxy primer, and the paint mixed with the epoxy primer is directly sprayed on the side of the exhaust limiting plate that is on the lift limit side of the exhaust valve plate to form a spray damping layer 4 . Constitute a specific coating structure, which can reduce vibration and noise.

[0040] The spraying thickness is controlled at 0.3-0.5mm. like image 3 Assembled in the manner shown: install the exhaust valve plate 2 in the groove valve plate 1, and then install the cold-rolled carbon structure sprayed with a 0.3mm-0.5mm thick spray damping layer 4 on the exhaust valve plate 2 ...

Embodiment 2

[0043] like Figure 4 , Figure 5 As shown, the present invention provides a noise reduction structure for a fully enclosed refrigeration compressor. The refrigeration compressor is provided with an exhaust valve, including a valve plate 1, an exhaust valve plate 2 and an exhaust valve plate limiting plate. The exhaust valve plate limiting plate is a cold-rolled carbon steel limiting plate 3, and a damping material layer is provided on the surface of the exhaust valve plate 2 on the cold-rolled carbon steel limiting plate 3. .

[0044] The damping material layer is a damping alloy cladding 5 .

[0045] The material of the damping alloy cladding 5 is Mn-Cu alloy.

[0046] The exhaust valve limiting plate described in this embodiment is made of damping alloy, which has good vibration damping performance, is not only a structural material, but also has high damping performance, such as Mn-Cu alloys, which have good vibration damping properties. It has high mechanical strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com