Manufacturing method of surface conduction electron emission source with uniform and controllable nano gaps

A nano-gap and electron-conducting technology, which is applied in the manufacture of discharge tubes/lamps, electrode system manufacturing, circuits, etc., can solve the difficulty of controlling the spacing and uniformity of nano-gap, the complicated process of making electron emission sources, and the failure of electron emission sources, etc. problem, achieve the effect of improving emission efficiency and uniformity, low cost, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

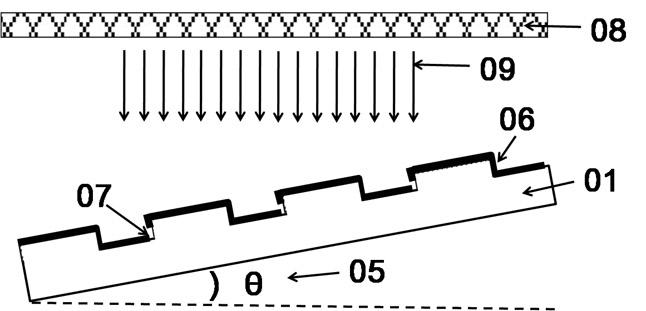

[0041] A specific embodiment comprises the following steps:

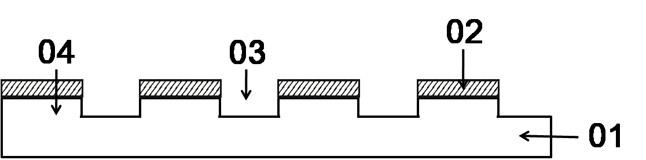

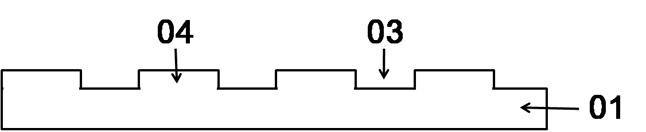

[0042] (S11) Fabrication of column pattern arrays:

[0043] Select a glass substrate of the required size for scribing, place the glass substrate in a cleaning solution with a volume ratio of Win-10: DI water = 3: 97, use an ultrasonic machine with a frequency of 32KHz to clean for 15 minutes, and spray for 2 minutes. Then place it in the cleaning solution with a volume ratio of Win-41: DI water = 5: 95, use an ultrasonic machine with a frequency of 40KHz to clean for 10 minutes, spray and rinse with circulating tap water for 2 minutes, and then use an ultrasonic machine with a frequency of 28KHz to clean it in DI Rinse in water for 10 minutes, blow dry with a nitrogen gun, and place in a clean oven at 50°C for at least 30 minutes for later use.

[0044] On the clean glass substrate 01, a layer of photoresist RZJ-304 was evenly coated by screen printing process, baked at 110°C for 20 minutes, and then exposed-deve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com