Terminal structure of channel power metal oxide semiconductor (MOS) device and manufacture method of terminal structure

A technology of MOS device and terminal structure, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as being susceptible to external influences and adverse device stability, and achieve chip cost and device reliability improvement and savings. The effect of mask plate times and protection breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

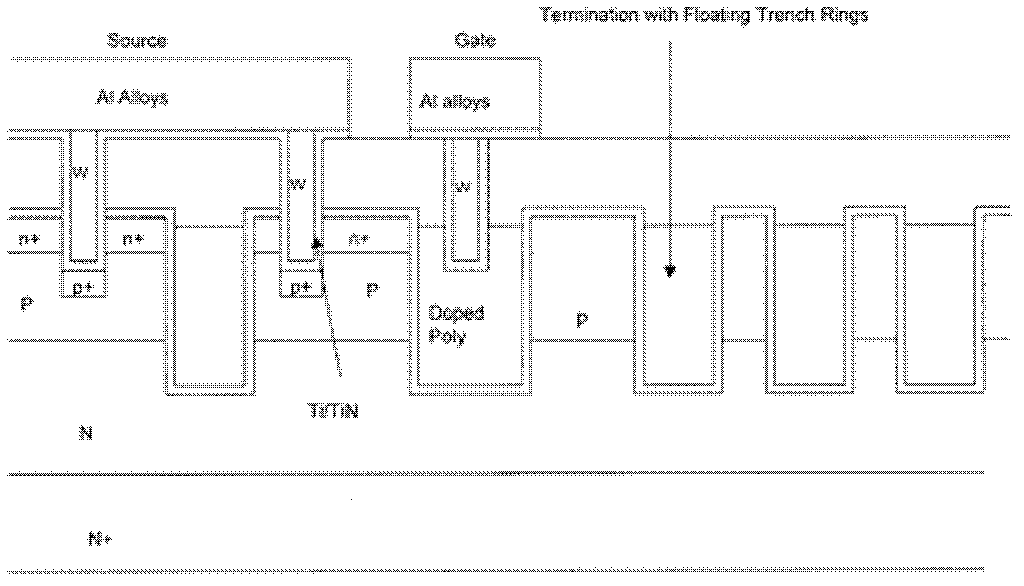

[0023] The present invention is described below in conjunction with accompanying drawing.

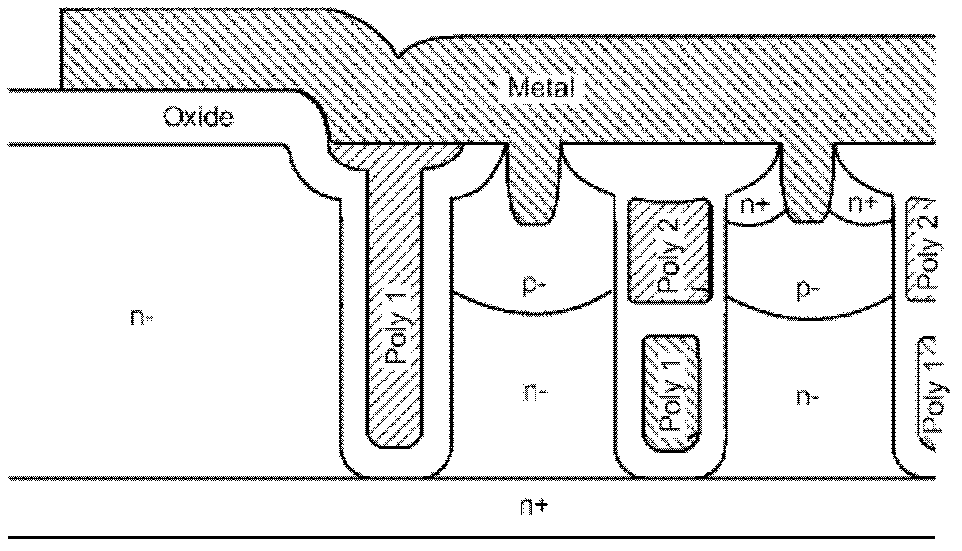

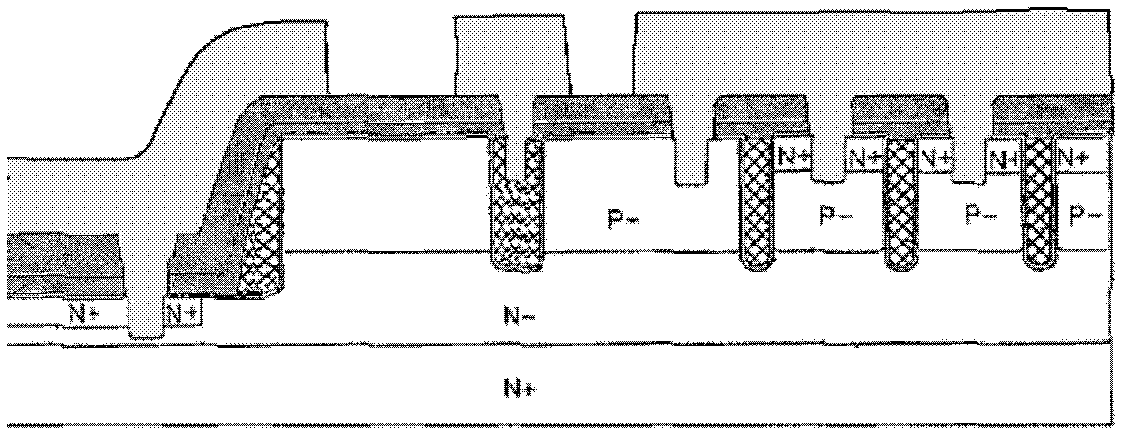

[0024] 1. In the terminal structure of the split gate trench power MOS device, the gate electrode lead-out structure and the corresponding lower split gate structure are produced under the same process conditions as the cells in the same device, as shown in the schematic diagram of the process steps in Figure 5 .

[0025] 2. In the process steps shown in Figure 5, the silicon nitride mask 1 is used to form a spacer oxide (Spacer Oxide) structure to etch out the trench gate structure, and it can also be used as the source electrode N+ ion implantation with the gate electrode lead-out part mask plate.

[0026] 3. Simulation curve of the breakdown characteristics of the split-gate trench MOSFET device. The breakdown voltage of the split-gate device is 35V (defined when the reverse drain-source current reaches 1×10 -12 device breakdown at A / μm).

[0027] 4. The internal current and poten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com