A kind of preparation method of lithium ion battery pole piece

A lithium-ion battery, pole piece technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of affecting battery charge and discharge performance, increasing electrolyte concentration gradient, insufficient active material capacity, etc. Effects of discharge performance and low temperature performance, improved mass specific capacity, and increased porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

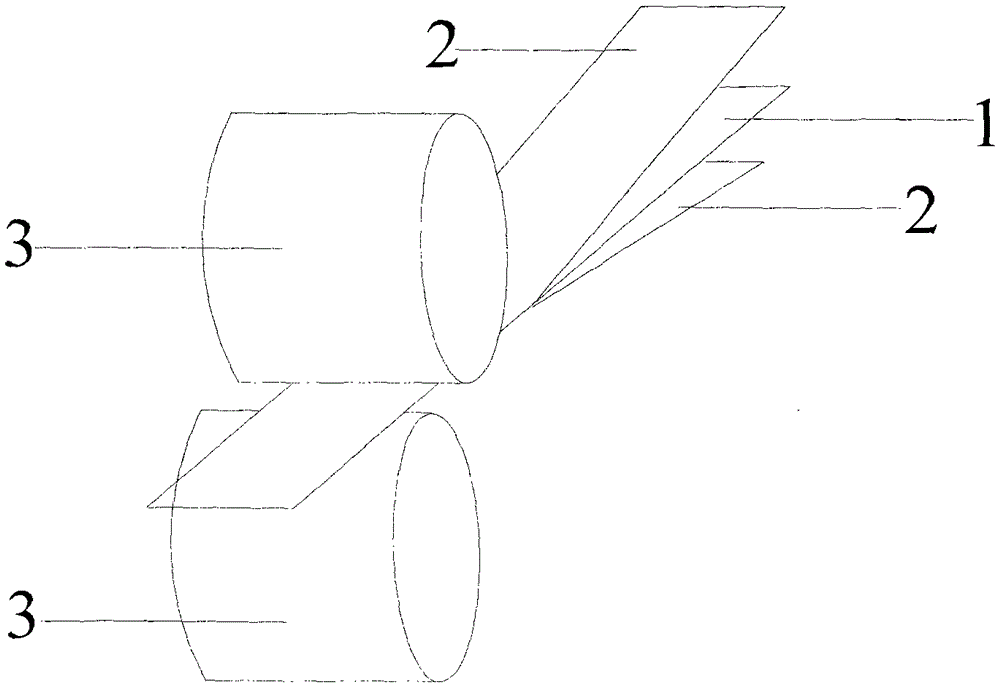

[0046] As described above in the manufacturing process of lithium-ion batteries, lithium cobalt oxide (LiCoO 2 ) as the positive electrode active material, polyvinylidene fluoride (PVDF) is used as the binder, and conductive carbon black is selected as the conductive agent. After the mixed slurry is coated on both sides of the positive electrode current collector made of aluminum foil, it is dried to obtain Positive electrode sheet, then the electrode sheet to be treated and the PP material porous film with a thickness of 20um are pressed together on the roller machine 3, so that the compacted density of the positive electrode sheet is 4.1g / cm 3 , and then remove the porous membrane to obtain the positive sheet.

[0047] High-energy-density graphite is used as the negative electrode active material, SBR (polystyrene, butadiene suspension) is used as the binder, CMC (sodium carboxymethylcellulose) is used as the thickener, and conductive carbon black is used as the conductive a...

Embodiment 2~9

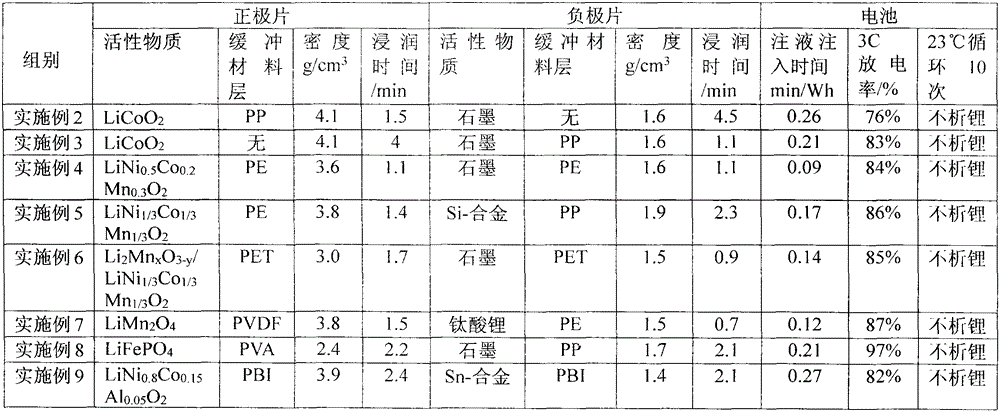

[0050] The positive electrode active material, negative electrode active material, buffer material layer material and pole piece compaction density used in Examples 2 to 9 are shown in Table 1. For the specific preparation process, please refer to the preparation of the positive electrode sheet, the preparation of the negative electrode sheet, and the electrolysis process described in the above paragraphs. Liquid composition and assembly testing process.

[0051] Table 1: The positive and negative active materials used in Examples 2 to 9, the material of the buffer material layer and the compaction density of the pole piece and the test results

[0052]

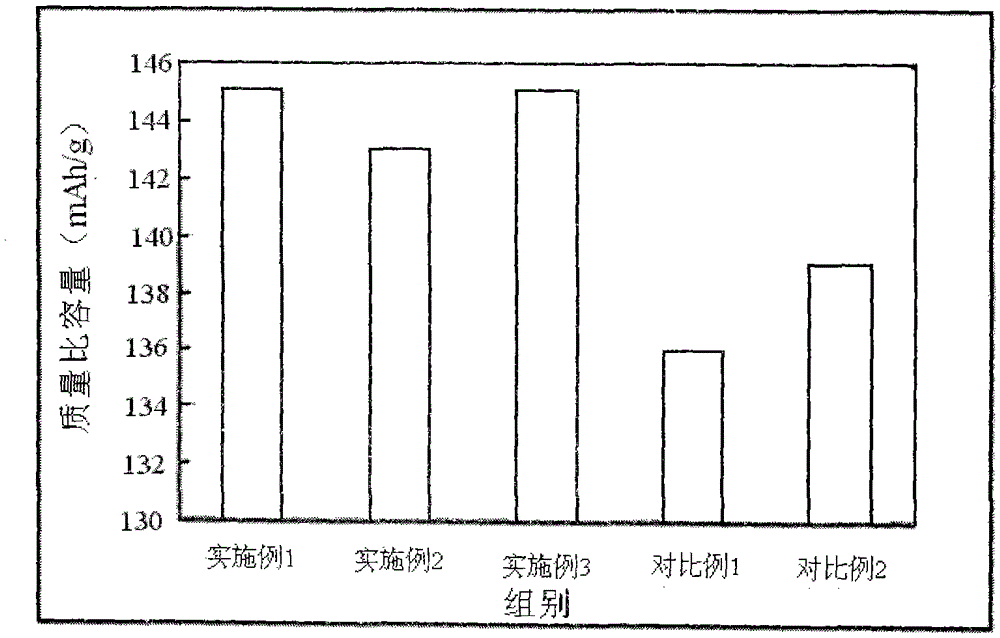

[0053] Simultaneously, the positive electrode sheet and the negative electrode sheet of embodiment 2~9 are tested as follows:

[0054] Drop 50uL electrolyte solution on the surface of the pole piece (the solvent is a mixture of ethylene carbonate and ethyl methyl carbonate with a mass ratio of 1:1, and the solute is 1MLiPF...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com