Melt blown fiber

A technology of melt-blown fibers and fibers, which is applied in the directions of fiber processing, fiber chemical characteristics, melt spinning, etc., and can solve problems such as limited mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The preparation of meltblown fibers and / or webs is described in more detail below.

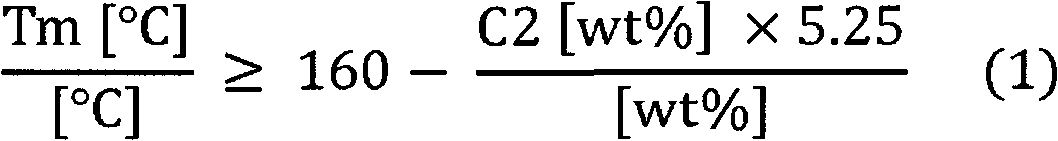

[0058] The propylene copolymers described in the present invention can be prepared by reacting propylene optionally with at least another C 2 to C 20 Alpha-olefins (comonomers) are polymerized to make part of the propylene copolymer. This fraction is then transferred to a subsequent gas phase reactor where propylene is then mixed with appropriately selected other C 2 to C 20The alpha-olefin (comonomer) reacts to make another fraction in the presence of the reaction product from the first step. This reaction sequence achieves reactor mixing of fractions (i) and (ii) constituting the propylene copolymer. Of course, the present invention can also adopt the following method: the first reaction is carried out in a gas phase reactor, and the second polymerization reaction is carried out in a slurry reactor such as a loop reactor. Further, it is also possible to reverse the manufacturing ...

Embodiment

[0072] 1. Definition / measurement method

[0073] Unless otherwise stated, the following definitions of terms and determination methods are applicable to the above description and the following examples of the present invention.

[0074] pass 13 C NMR spectroscopy to quantify isotacticity in polypropylene

[0075] By quantitative 13 C Isotacticity was determined by nuclear magnetic resonance (NMR) spectroscopy. The experimental parameters are adjusted to ensure the determination of quantitative spectra for this specific task, for example as described in: S. Berger and S. Braun, 200 and More NMR Experiments: A Practical Course, 2004, Wiley-VCH, Weinheim . Quantitative values were calculated using simple corrected ratios of signal integrals for representative sites in a manner known in the art. Isotacticity is determined at the pentavalent level (ie the mmmm portion of the pentavalent distribution).

[0077] The relative amount of 2,1-inser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| To melt | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com